shock absorbing parts

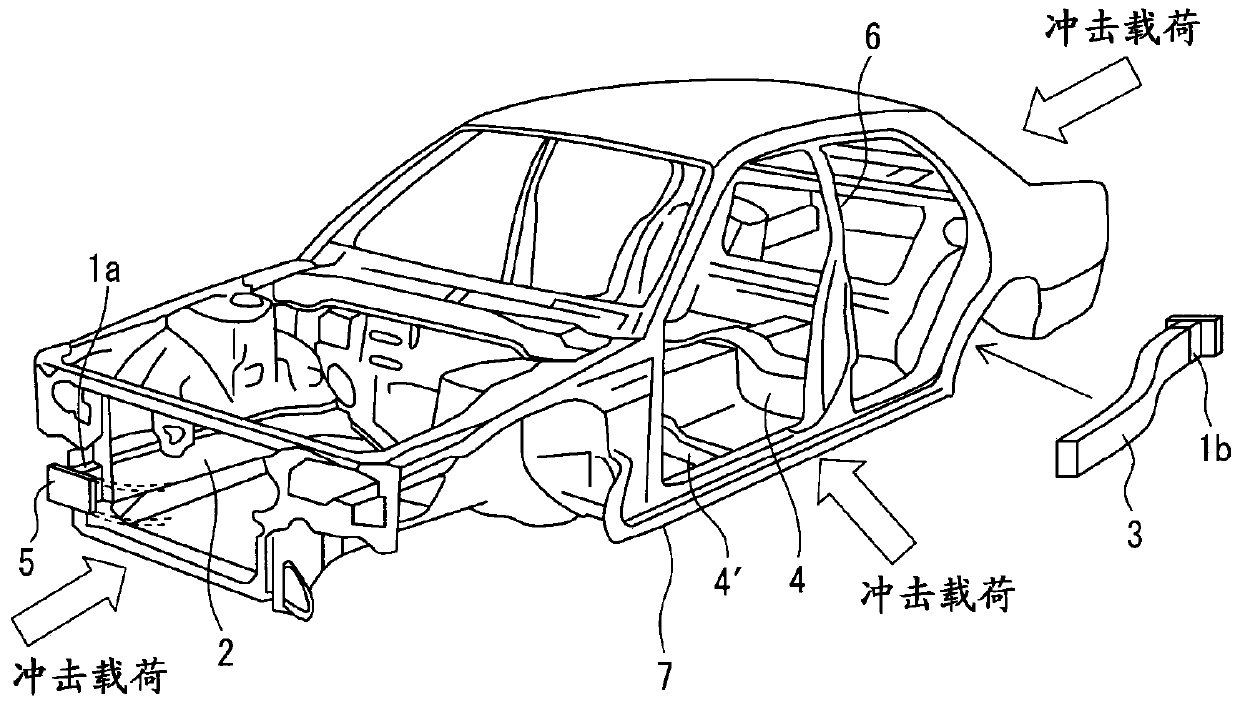

A technology of impact absorption and components, applied in the direction of vehicle components, substructure, superstructure, etc., to achieve the effect of ensuring energy absorption and increasing energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

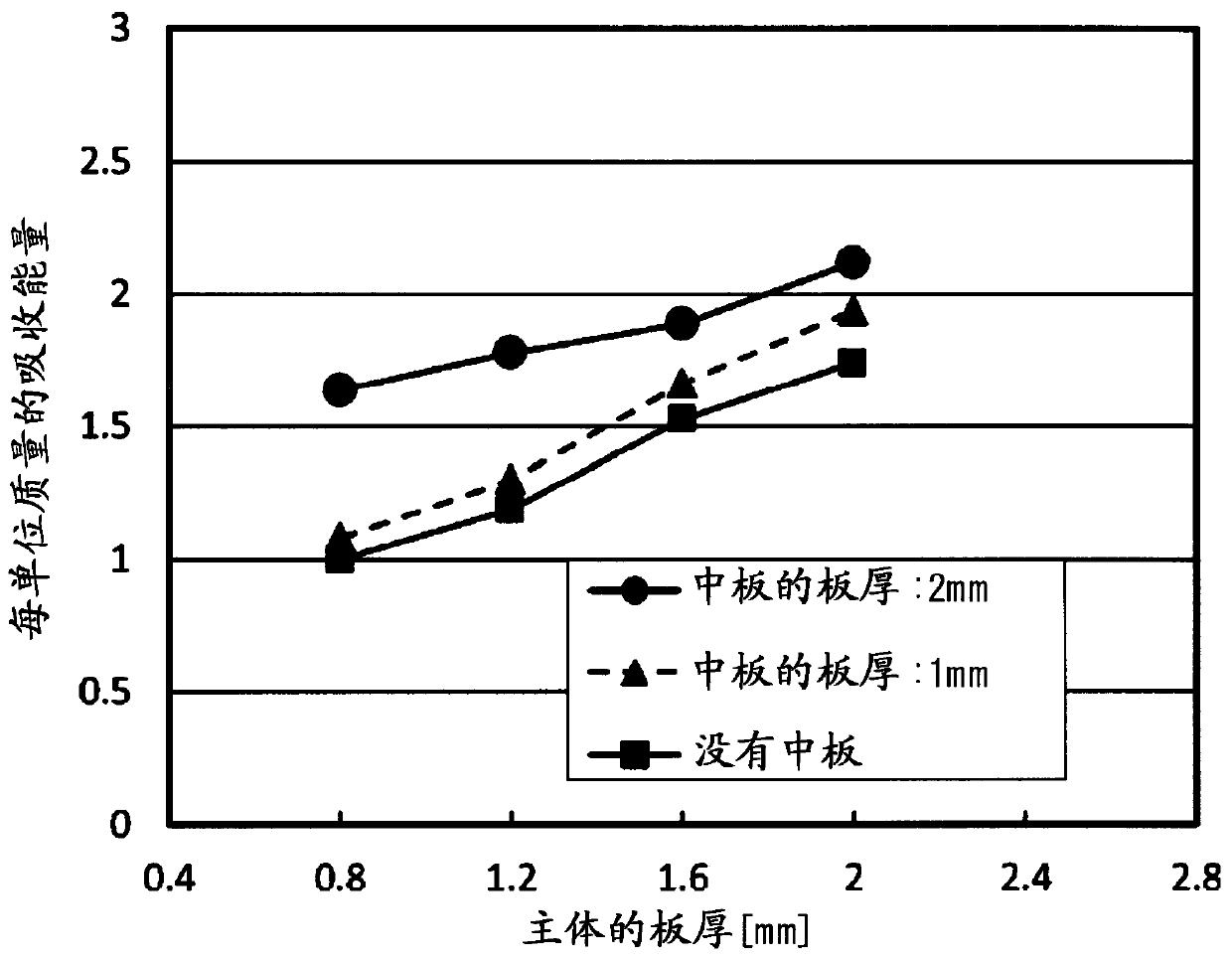

[0103] In order to confirm the effect of the impact absorbing member of this embodiment, an impact test was performed.

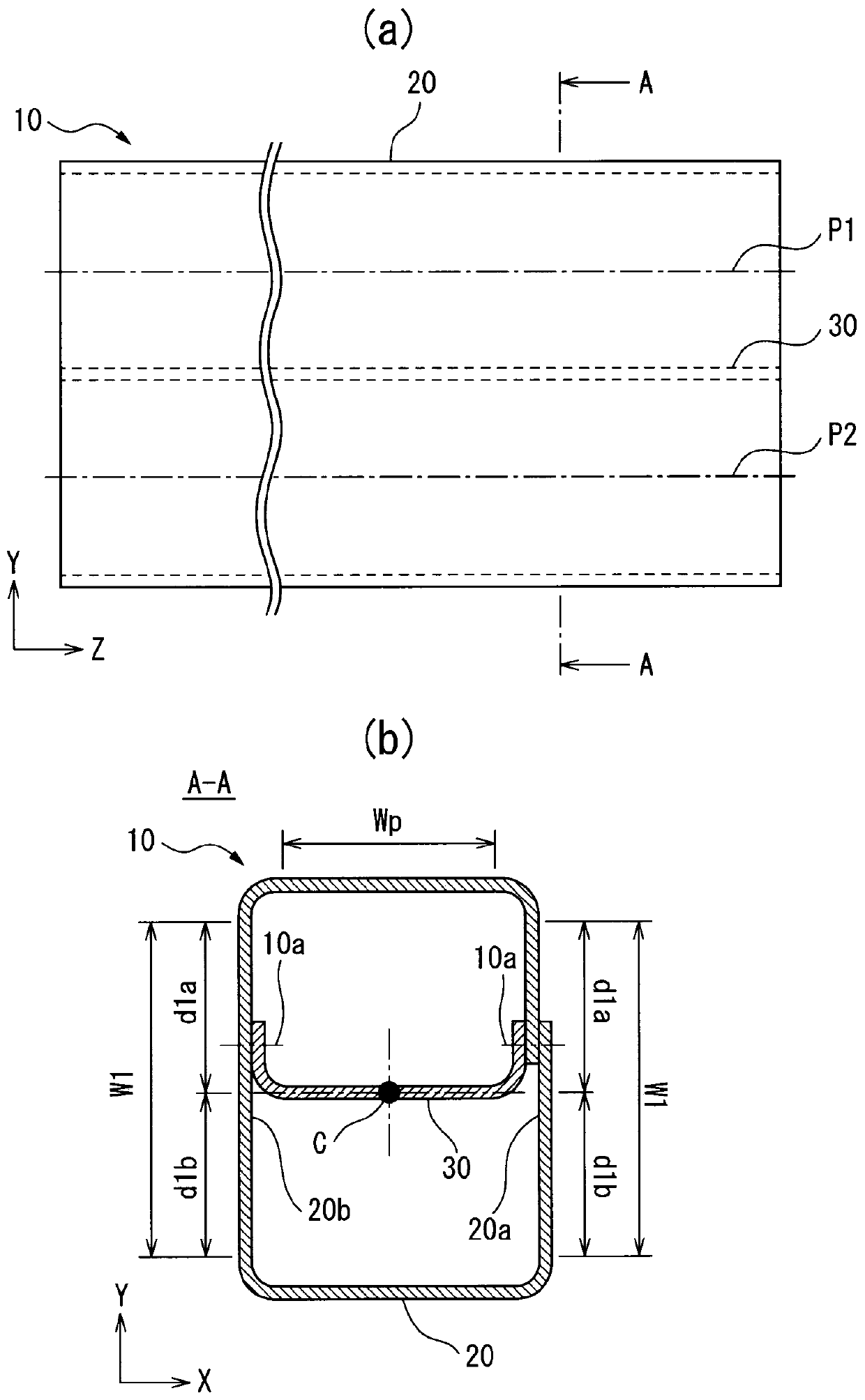

[0104] In this test, an analysis was performed to simulate a drop-weight impact test. Specifically, in the figure 2 The impact absorbing member of the shape shown is arranged such that the axial direction is along the vertical direction, and a collision body with a mass of 700 kg is dropped from a height of 13.8 m to cause the collision body to collide with one end of the impact absorbing member. At this time, the axial load and the axial displacement of the collision body are calculated, and the relationship between the load and the displacement is obtained. In addition, for one of the long side surfaces of the impact absorbing member after the impact test, the displacement in the direction (X direction) perpendicular to the surface including the welded portion was obtained. The displacement in the X direction is on both sides of the middle plate, specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com