A Waste Heat Power Generation System with Conical Rotor Generator

A conical rotor and generator technology, which is applied in the direction of machines/engines, electromechanical devices, electrical components, etc., can solve the problems of heat waste, high pressure, high temperature, etc., to reduce mechanical friction loss, low manufacturing cost, and long maintenance cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects.

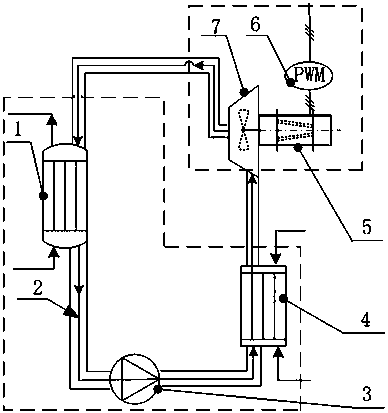

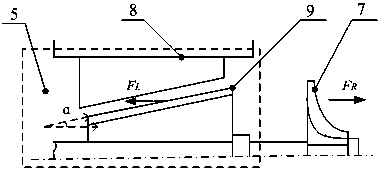

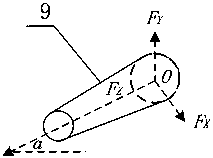

[0014] Such as figure 1 As shown, the waste heat power generation system with a conical rotor generator of the present invention is composed of three parts: working medium, heat exchange device and electrical system, wherein the working medium is an organic medium (2), and R245fa, R123 , R134a, R600a; the heat exchange device consists of a condenser (1), an evaporator (4) and a working medium pump (3); the electrical system consists of a radial turbo expander (7), a PWM converter (6 ) and conical rotor generator (5).

[0015] In the system, the outlet of the condenser (1) is connected to the inlet of the working med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com