Adaptive hard-rock impact rotary crushing system

A rotary crushing and self-adaptive technology, which is applied in testing machinery, earthwork drilling, cutting machinery, etc., can solve problems such as long auxiliary excavation time, large amount of pick damage, and large excavation tasks, and achieves low cost and high maintenance. The effect of small amount and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

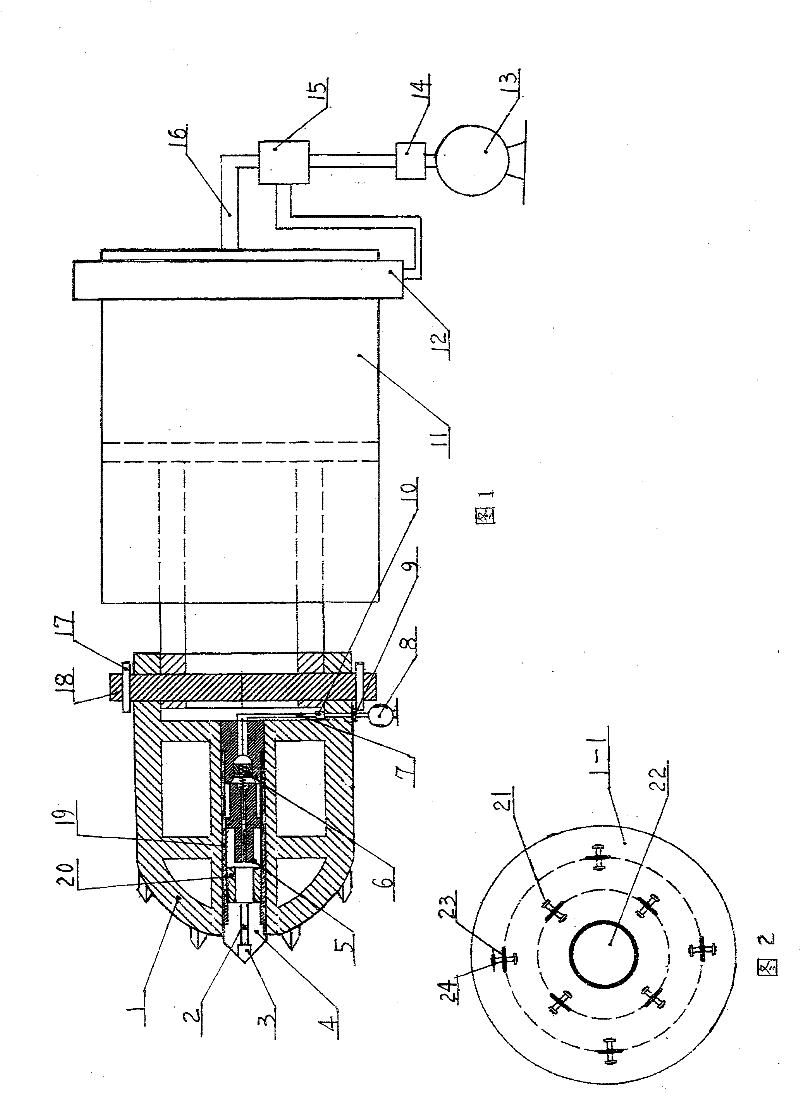

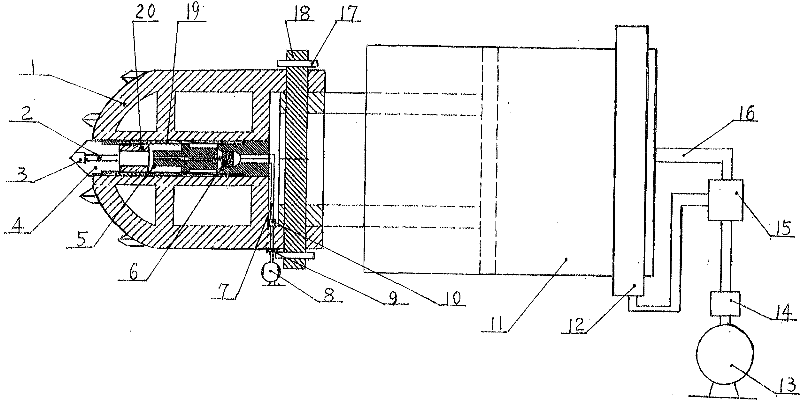

[0010] Examples, see attached figure 1 , 2 , the right end and the lower end of the hydraulic motor 12 of the self-adaptive hard rock impact rotary crushing system are respectively connected with a hydraulic control valve 15 through a hydraulic pipeline 16, and the lower part of the hydraulic control valve 15 is connected with a hydraulic control module 14 through a hydraulic pipeline 16, and the hydraulic control A hydraulic pump 13 is connected with a hydraulic pipeline 16 below the module 14 . The left end of hydraulic motor 12 is provided with a propulsion hydraulic master cylinder 11, advances hydraulic master cylinder 11 left end sets a rotary knife rest 1, is connected with support pin 18 between propulsion hydraulic master cylinder 11 and rotary knife rest 1, and support pin 18 two The ends are fixed with locking pins 17 respectively. Rotary knife rest 1 front end face is provided with hob support surface 1-1, center hole 22, is evenly distributed on the hob support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com