A mechanical molecular spring vibration isolation buffer device

A technology of molecular springs and buffer devices, which is applied in the field of vibration isolation buffer devices, can solve the problems of low natural frequency and small static deformation, low working pressure, and incompatibility, achieving multiple design parameters, low working water pressure, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

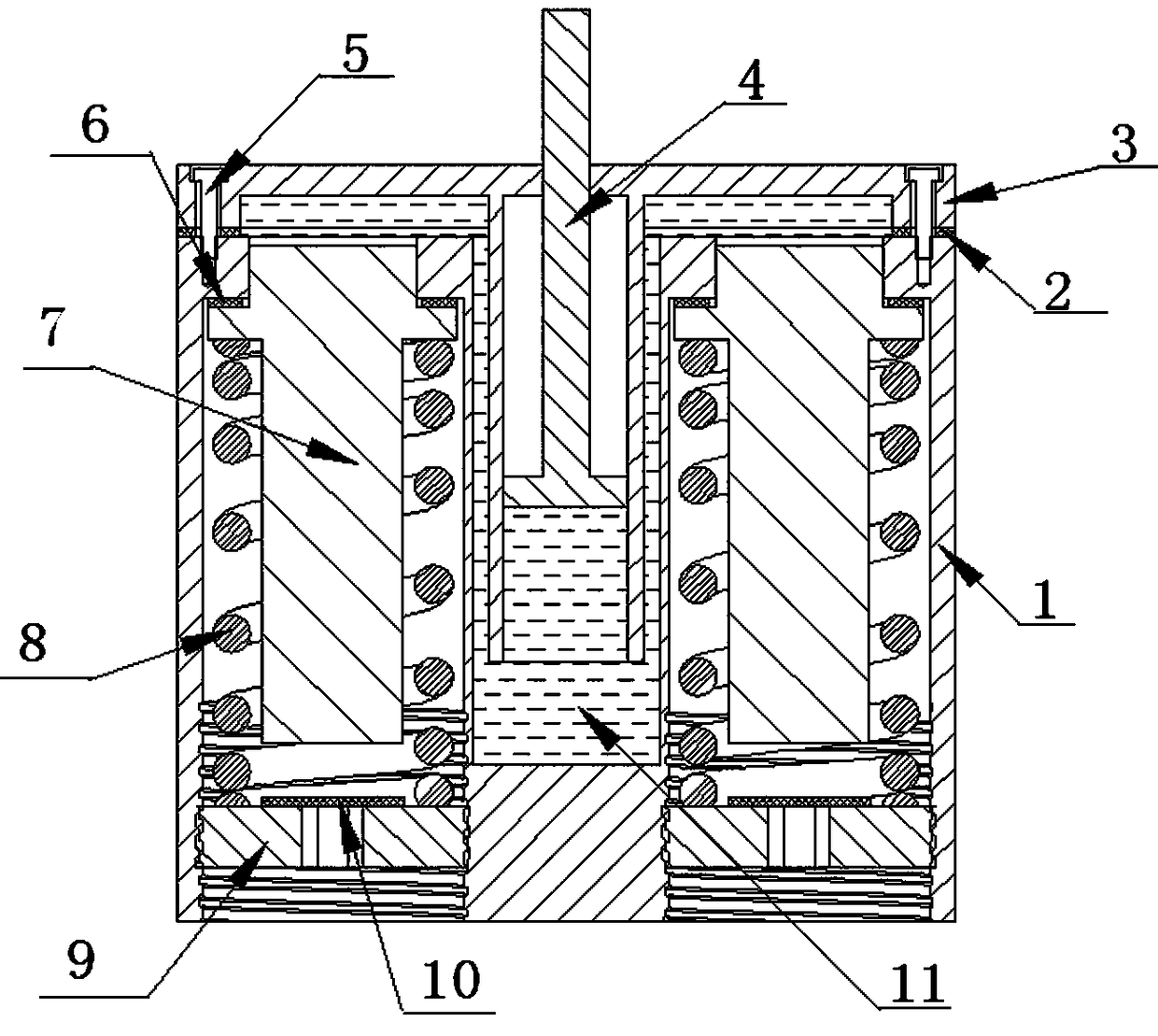

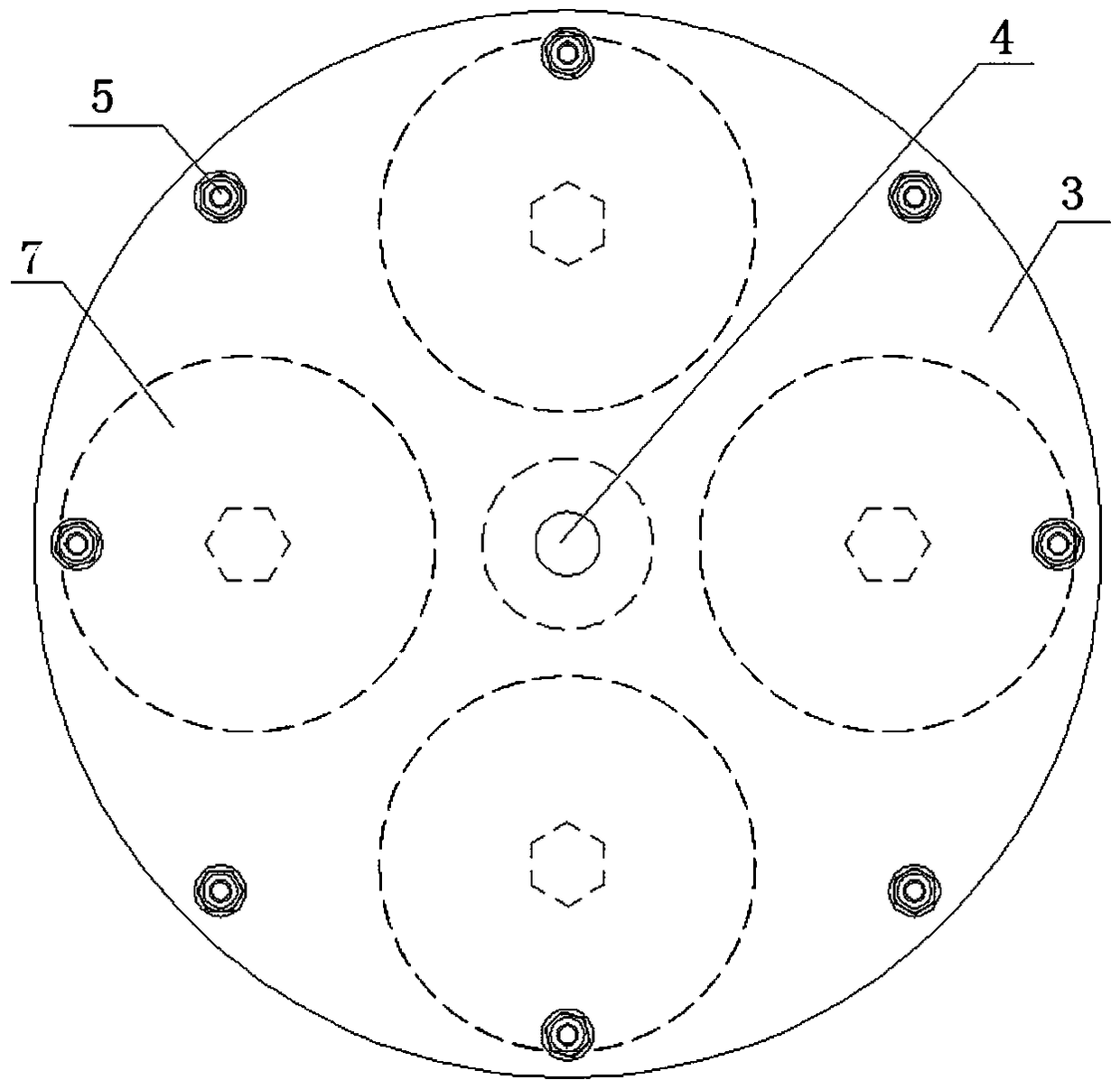

[0025] Such as figure 1 and figure 2 As shown, a mechanical molecular spring vibration isolation buffer device, the mechanical molecular spring vibration isolation buffer device includes a cylinder 1, a sealing ring 2, an upper end cover 3, a main piston 4, a countersunk screw 5, a rubber washer 6, and a slave piston 7. Spring 8, pre-tightening block 9, rubber pad 10 and water 11, the water 11 is sealed in the closed chamber composed of the master cylinder 1, the upper end cover 3, the master piston 4 and the slave piston 7, forming a sealed hydraulic container The sealing ring 2 is located on the contact surface between the cylinder body 1 and the upper end cover 3, and the upper end cover 3 is provided with 8 screw holes, and the cylinder body 1 and the upper end cover 3 are fixedly connected by countersunk screws 5 in the screw holes; The middle part of the upper end cover 3 is provided with a hollow shaft protruding into the cylinder body, the main piston 4 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com