A display panel and its manufacturing method

A manufacturing method and display panel technology, which is applied in the field of color display, can solve the problems that the display is difficult to realize and optical flatness, and achieve the effects of avoiding deviation and improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

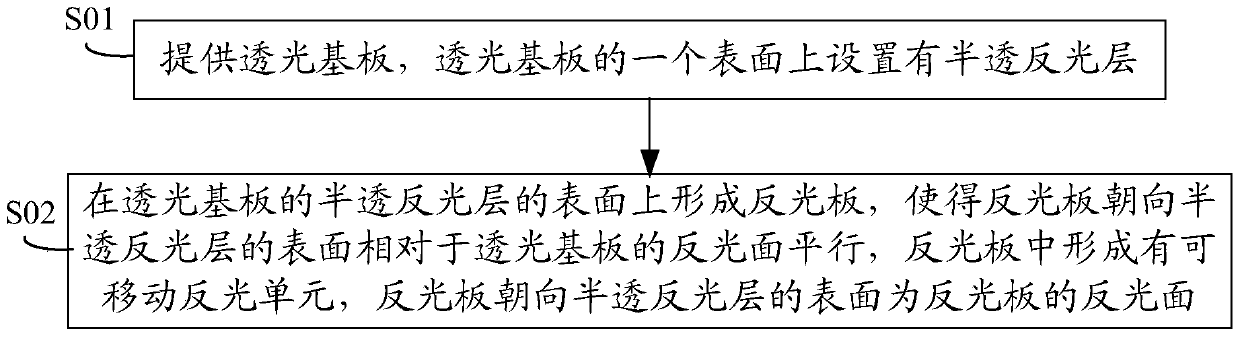

Method used

Image

Examples

Embodiment 2

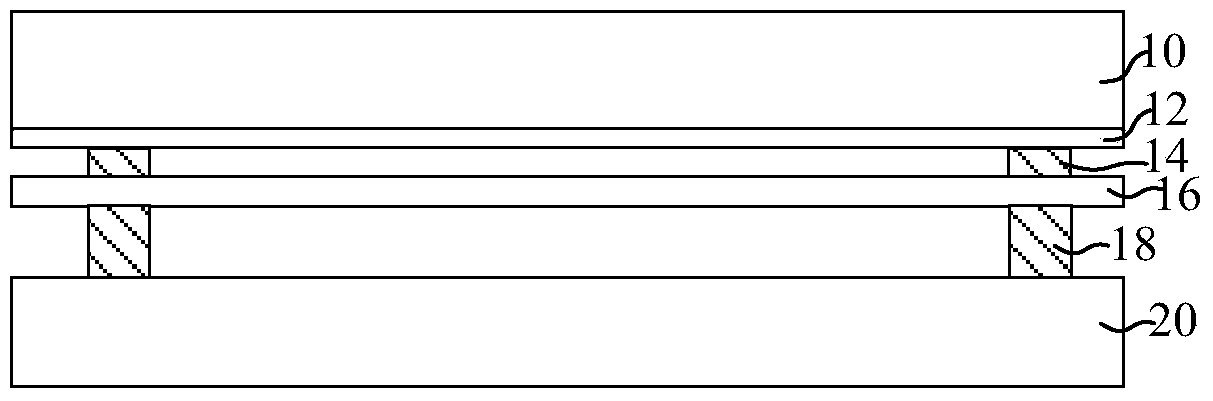

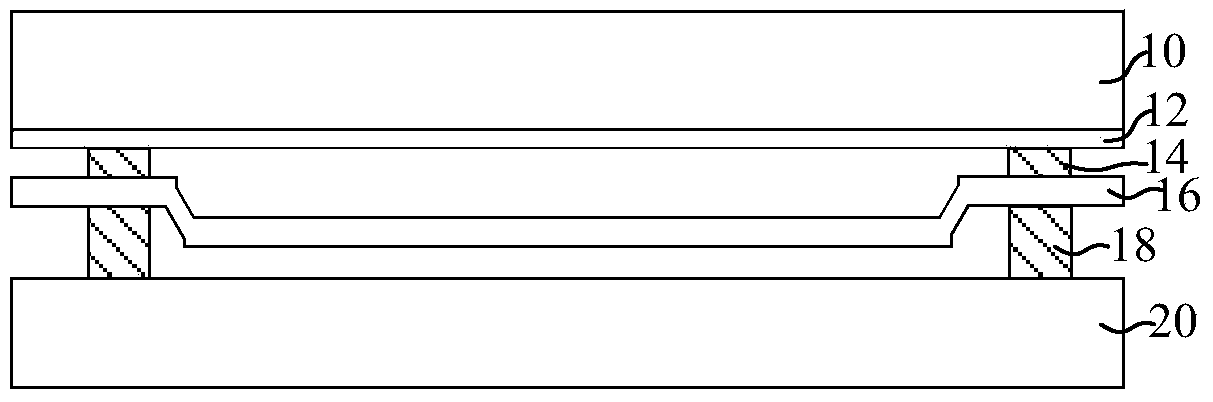

[0079] The manufacturing method of Embodiment 1 has been described in detail above. In Embodiment 2, the same as Embodiment 1, the heat-pressing process is used to laminate the formed light-transmitting substrate and reflective plate, and then, heat-pressing process, so that the surface of the reflective plate facing the semi-transparent reflective layer is parallel to the reflective surface of the light-transmitting substrate. After the pressing process, while flattening the interference surface, the fixation of the reflective plate or the light-transmitting substrate is realized. Parts that are different from those in Embodiment 1 will be described below, and the same parts will not be described again.

[0080] In step S201, a light-transmitting substrate is provided, and a light-transmitting substrate 100 is provided, and a semi-transparent and reflective layer 110 is provided on one surface of the light-transmitting substrate 100. Refer to Figure 4 shown.

[0081] In st...

Embodiment 3

[0092] The difference from Embodiment 1 and Embodiment 2 is that in this embodiment, after the light-transmitting substrate is provided, a molding plate with light-reflecting units is directly formed on the surface of the translucent reflective layer of the light-transmitting substrate through an injection molding process, and then A reflective film is formed on the surface of the forming plate facing the translucent reflective layer, thereby forming a reflective plate. Parts different from those in Embodiment 1 and Embodiment 2 will be described below, and the same parts will not be repeated.

[0093] In step S301, a light-transmitting substrate is provided, and a light-transmitting substrate 100 is provided, and a semi-transparent and reflective layer 110 is provided on one surface of the light-transmitting substrate 100. Refer to Figure 4shown.

[0094] Same as step S101 in Embodiment 1.

[0095] In step S302, a forming plate 201 with a plurality of reflective units 210 ...

Embodiment 4

[0104] The difference from Embodiment 1 and Embodiment 2 is that in this embodiment, after the light-transmitting substrate is provided, a molding plate with a light-reflecting unit is directly formed on the surface of the translucent reflective layer of the light-transmitting substrate through a photocuring molding process , and then form a reflective film on the surface of the forming plate facing the translucent reflective layer, thereby forming a reflective plate. Parts different from those in Embodiment 1 and Embodiment 2 will be described below, and the same parts will not be described again.

[0105] In step S401, a light-transmitting substrate is provided, and a light-transmitting substrate 100 is provided, and a semi-transparent and reflective layer 110 is provided on one surface of the light-transmitting substrate 100. Refer to Figure 4 shown.

[0106] Same as step S101 in Embodiment 1.

[0107] In step S402, a molding plate 201 with a plurality of reflective unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com