High-safety electric power supply device

A technology of power supply and safety, which is applied in the direction of coupling devices, components of connecting devices, circuits, etc., can solve the problems of easy wear of plugs, poor contact of circuits, and low safety, so as to improve stability and accuracy, Improve the convenience of installation and reduce the effect of personnel operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

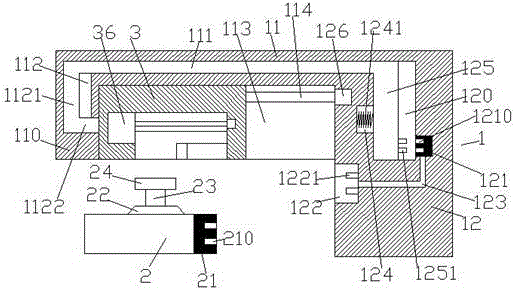

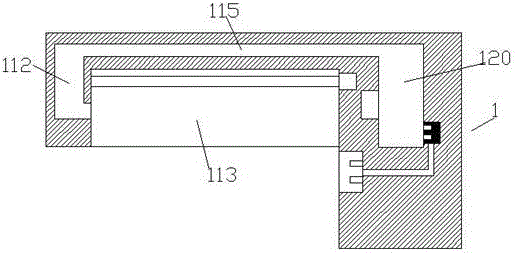

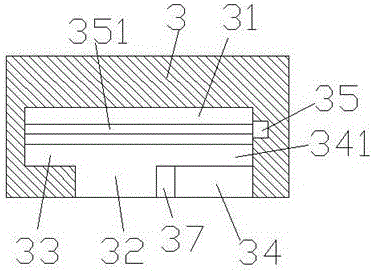

[0022] Such as Figure 1-Figure 6 As shown, a high-safety power supply device of the present invention includes a power supply base 1 composed of an execution part 11 and a power supply part 12, and a plug 2 for matching and connecting with the power supply base 1. A first chute 113 is provided at the lower right bottom of the execution part 11, and a first screw 114 is arranged inside the first chute 113, and the right end of the first screw 114 is power-connected with the first motor 126, and the first A screw rod 114 is provided with a locking guide slider 3 that is threadedly connected, and a second chute 31 is provided in the locking guide slider 3 , and a second screw rod 351 is provided in the second chute 31 . The right end of the two screw rods 351 is power-connected with the second motor 35, the bottom of the second chute 31 is provided with an installation groove 32, and the locking guide slider 3 on the left side of the installation groove 32 is provided with an ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com