Pre-twisted suspension clamp with monitoring function

A suspension clamp and pre-twisting technology, which is applied in the direction of measuring devices, cable suspension devices, instruments, etc., can solve the problem of difficult to measure the force of the suspension clamp, the deformation of the clamp, and the difficulty of accurately knowing the force of the suspension clamp Problems such as the heating of the wires on the hanging wire clamps, etc., to avoid tip discharge phenomenon, reliable performance, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

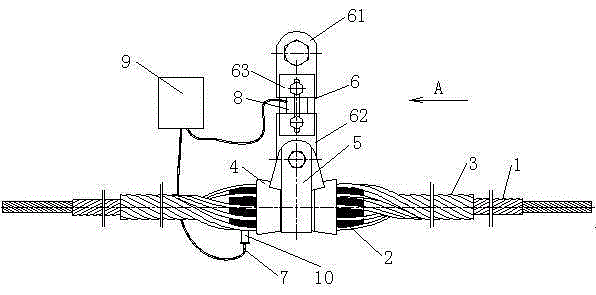

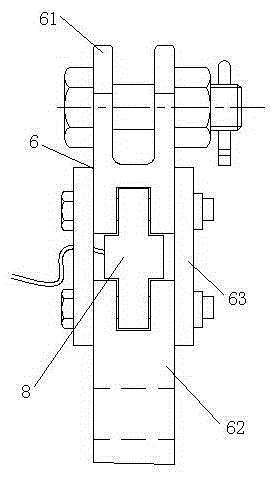

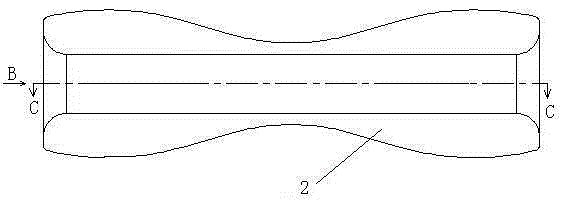

[0023] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 7 , attached Figure 8 , a pre-twisted suspension wire clamp with monitoring function of the present invention is composed of an inner twisted wire 1, a liner 2, an outer twisted wire 3, a suspension casing 4, a hoop 5, a hanging plate 6, a temperature sensor 7, and a tension sensor 8 , a controller 9, and a temperature sensor seat 10. The inner skein 1 is wound on the transmission wire; the two liners 2 are symmetrically arranged at the center of the inner skein 1; the outer skein 3 is wound around the inner skein 1 and the liner 2 Above; the two hanging casings 4 are symmetrically arranged in the center of the liner 2 wound with the outer twisted wire 3, and are tightly held by the hoop 5; the hanging plate 6 is connected with the hanging casing 4 and the hoop 5 through bolts; the liner 2 Connected with the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com