Pipeline dredger of rotary crushing reverse jet propulsion

A pipeline dredger and pipe protection technology is applied in the field of pipeline dredgers for rotary crushing and reverse jet propulsion, which can solve the problems of difficulty in crushing and easy obstruction, and achieve the effect of reducing friction and promoting the use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

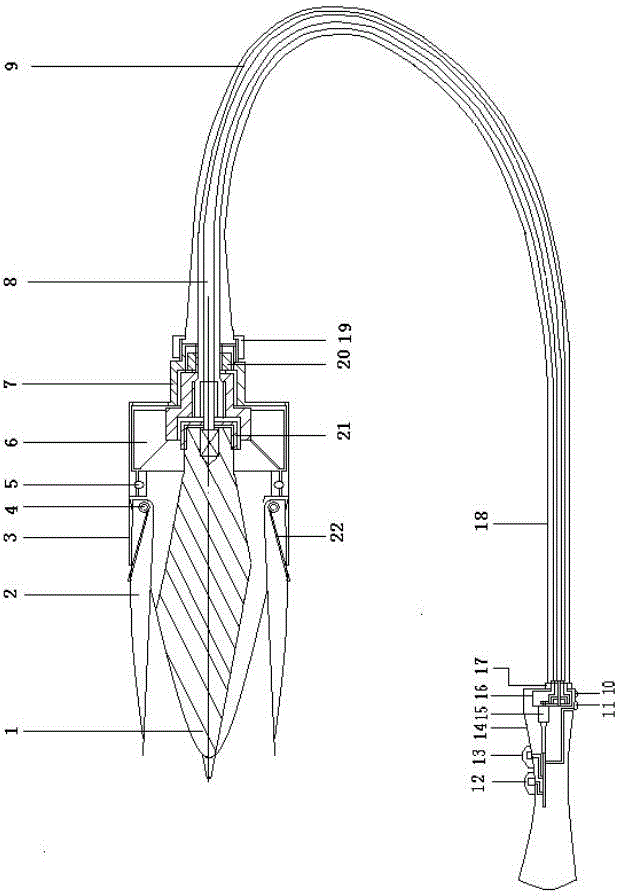

[0028] A pipe dredger for rotary pulverization and anti-jet propulsion of the present invention comprises a handle 14, a transmission flexible shaft and a motor 15, the transmission flexible shaft is connected with the handle 14, the motor 15 is arranged on the handle 14, and a shaft head 1. Chopping blade 2. Chopping knife reducer 3. Anti-spray impeller 6 and bracket 7. The transmission flexible shaft is mainly composed of transmission flexible shaft a8, transmission flexible shaft b9 and transmission flexible shaft protection tube 18 from inside to outside. The motor 15 can drive the transmission flexible shaft a8 and the transmission flexible shaft b9 to rotate, the length of the transmission flexible shaft a8 is greater than the length of the transmission flexible shaft b9, the length of the transmission flexible shaft b9 is greater than the length of the transmission flexible shaft protection tube 18, and the transmission flexible shaft a8. The first ends of the transmissi...

Embodiment 2

[0030] A pipe dredger for rotary pulverization and anti-jet propulsion of the present invention comprises a handle 14, a transmission flexible shaft and a motor 15, the transmission flexible shaft is connected with the handle 14, the motor 15 is arranged on the handle 14, and a shaft head 1. Chopping blade 2. Chopping knife reducer 3. Anti-spray impeller 6 and bracket 7. The transmission flexible shaft is mainly composed of transmission flexible shaft a8, transmission flexible shaft b9 and transmission flexible shaft protection tube 18 from inside to outside. The motor 15 can drive the transmission flexible shaft a8 and the transmission flexible shaft b9 to rotate, the length of the transmission flexible shaft a8 is greater than the length of the transmission flexible shaft b9, the length of the transmission flexible shaft b9 is greater than the length of the transmission flexible shaft protection tube 18, and the transmission flexible shaft a8. The first end of the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com