Automatic cleaning system for ink box of printer

An automatic cleaning and printer technology, applied to printing devices, printing, etc., can solve the problems of time-consuming cleaning of inkjet devices, and achieve the effects of simple structure, flow control, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

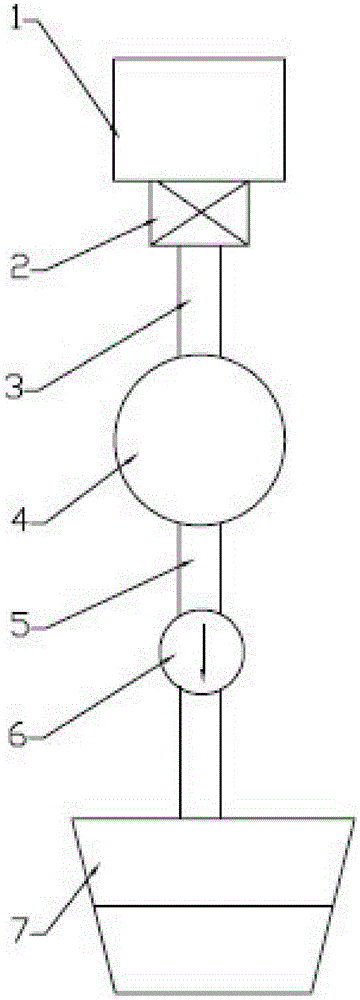

Examples

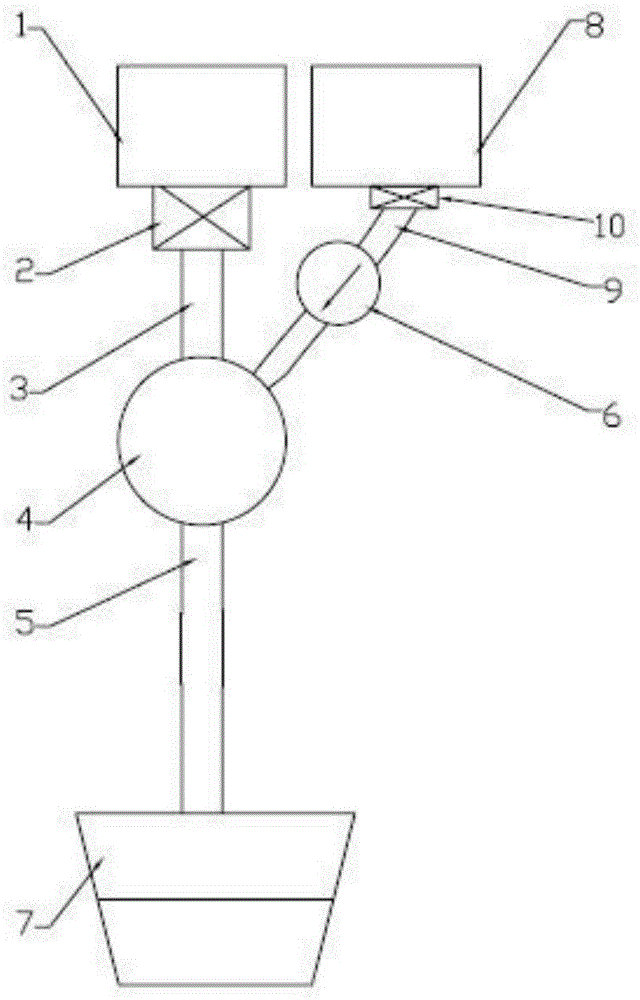

Embodiment 2

[0017] In Example 2, during printing, the auxiliary valve 10 is closed and the control valve 2 is opened.

[0018] When cleaning, close the control valve 2 and open the auxiliary valve 10, the cleaning agent in the cleaning box 8 will reach the nozzle 7 along the pipeline.

[0019] In Example 1 and Example 2, during printing, the dome cover 4 will control the flow of the ink, so that the ink in the nozzle 7 is fully mixed to prevent excessive ink; during cleaning, the dome cover 4 will clean The flow of the cleaning agent is controlled to ensure that the cleaning agent is evenly distributed inside the entire nozzle 7, which makes cleaning more clean and thorough.

[0020] In specific use, the ink cartridges and the connecting devices are in one-to-one correspondence in Embodiment 1, but multiple ink cartridges and connecting devices can be used in Embodiment 1, and all the ink cartridges and connecting devices are connected to one nozzle. The same is true for Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com