Adjusting valve capable of adjusting prestress

A control valve and prestressing technology, applied in the field of control valve, can solve problems such as water resource waste and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

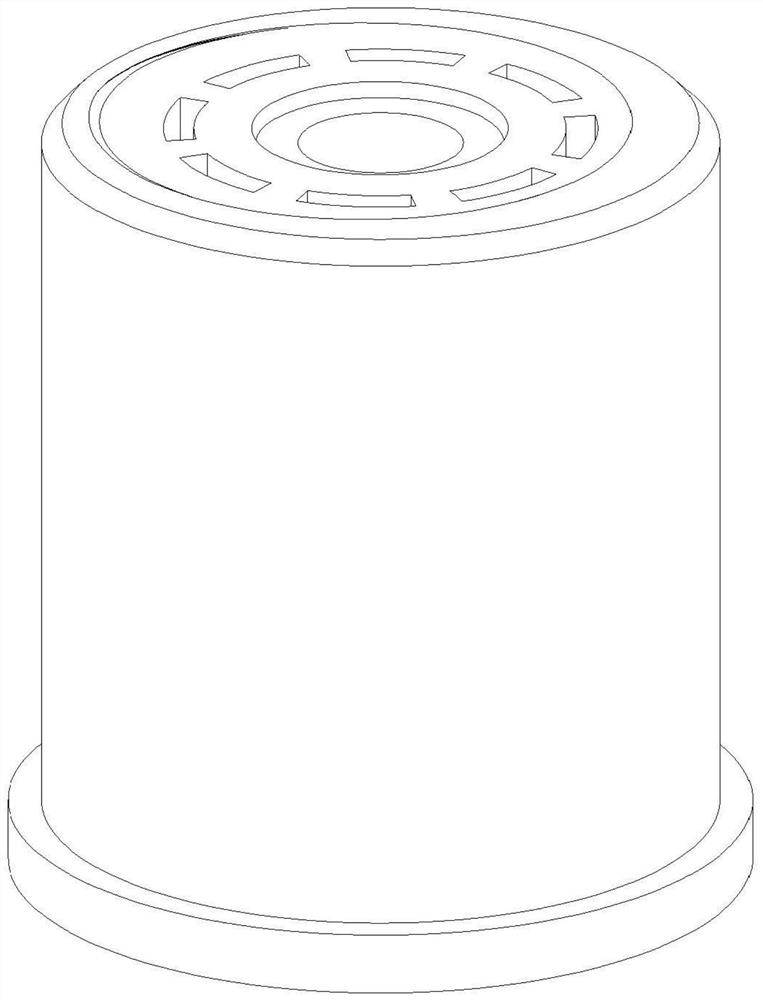

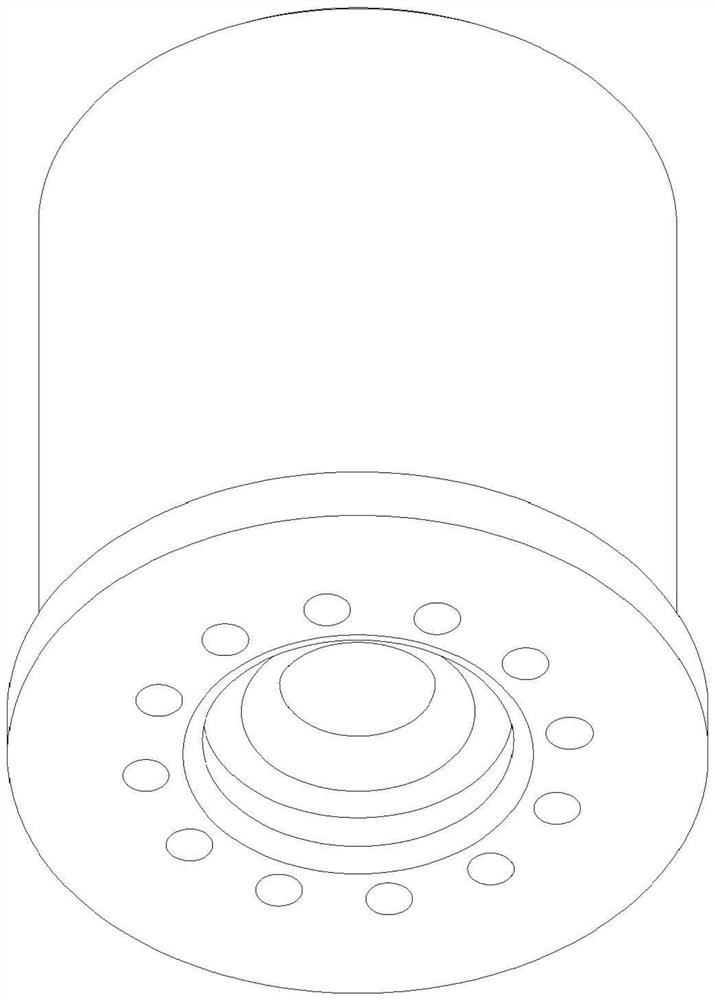

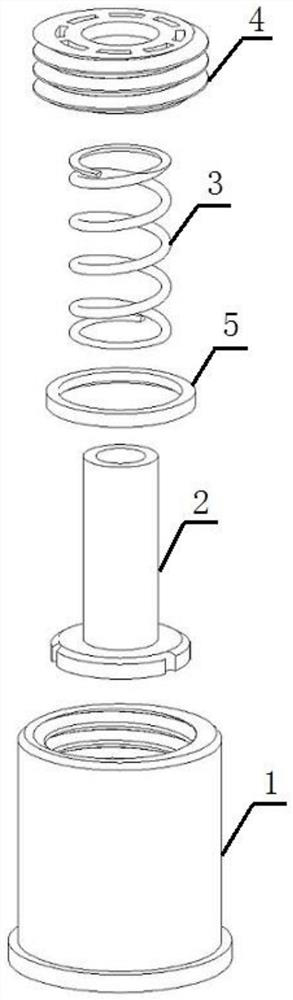

[0031] Such as Figure 1 to Figure 8 As shown, a regulating valve capable of adjusting the prestress, hereinafter referred to as the regulating valve, is composed of a valve seat 1, a valve core 2, a spring 3, and a valve sleeve 4. The valve seat 1 is provided with a valve seat through hole passing through the valve seat. The inner wall of the through hole of the valve seat near the water outlet is provided with an internal thread, correspondingly, the valve sleeve is provided with a matching external thread, and the inner wall of the valve seat between the internal thread of the valve seat and the water inlet end is provided with a positioning flange 5, The diameter of the through hole of the valve seat between the positioning flange and the water inlet is gradually enlarged, and the inner wall of the through hole of the valve seat between the positioning flange and the water inlet is provided with a plurality of outwardly sunken secondary water channels 11; end screwed into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com