Furnace body cutting device of biomass gasifier

A technology of cutting device and gasifier, which is applied in the direction of combination device, chemical instrument and method, separation method, etc., can solve the problems of easy leakage of high-temperature cutting steam and poor fixing effect of workpiece, and achieves increased contact time and increased The effect of cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

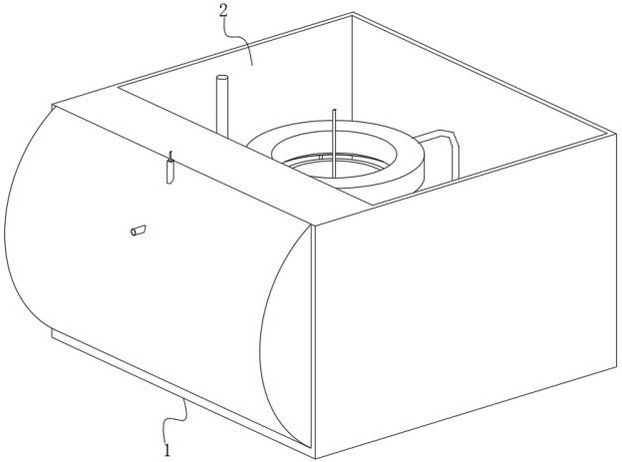

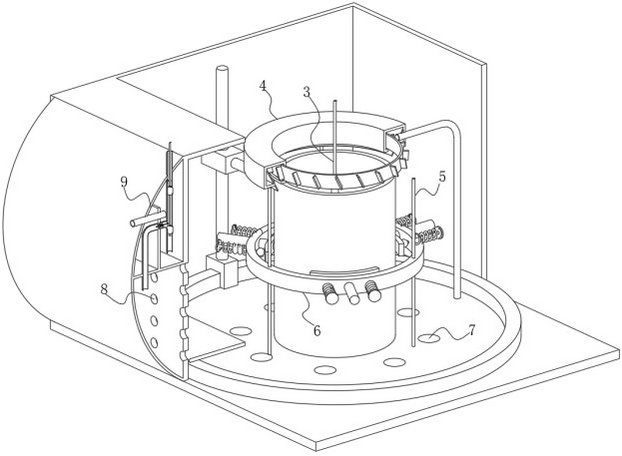

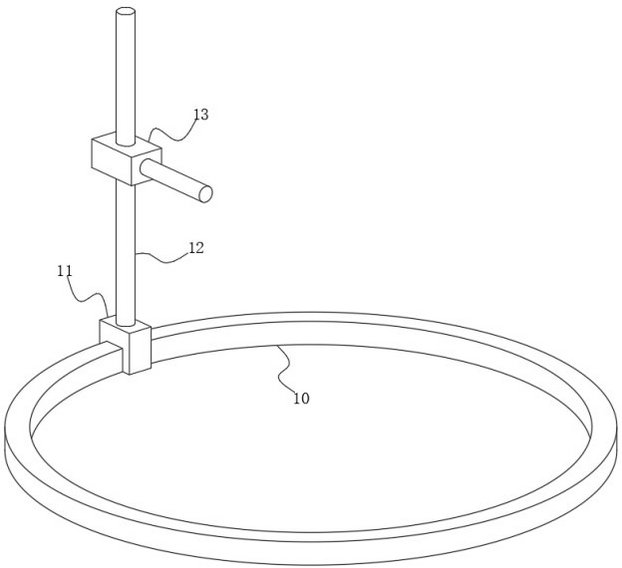

[0036] see Figure 1-10 , the present invention provides a technical solution: a furnace body cutting device for a biomass gasification furnace, comprising a bottom plate 1, an outer cover 2 is fixedly connected to the upper surface of the bottom plate 1, and a rotating machine 3 is arranged inside the outer cover 2, and the rotating machine 3 An air cooler 4 is arranged on the outside of the air cooler 4, a fixing rod 5 is fixedly connected to the lower surface of the air cooler 4, and a fixing machine 6 is slidably connected to the outer surface of the fixing rod 5. The port 7 is opened in the wall of the bottom plate 1, the wall on the left side of the outer cover 2 is provided with a through hole 8, the outside of the through hole 8 is provided with a suction machine 9, the upper surface of the bottom plate 1 is fixedly connected with an annular guide rail 10, the annular guide rail 10 A slider 11 is slidably connected to the outer surface of the slider 11 , a guide rod 12...

Embodiment 2

[0043] see Figure 1-10 , the present invention provides a technical solution: on the basis of the first embodiment, the suction machine 9 includes a side cover 30, the upper surface of the side cover 30 is fixedly connected with a fixing plate 31, and the lower surface of the side cover 30 is rotatably connected with a rotating plate 32. The top of the turning plate 32 is provided with a T-shaped plate 33, the inner surface of the T-shaped plate 33 is fixedly connected with a water inlet pipe 34, and the right end of the water inlet pipe 34 is provided with a purification pipeline 35. The inner surface of the pipe 40 is movably connected with a regulating valve 41, the right side of the regulating valve 41 is provided with a connecting pipe 42, the wall of the connecting pipe 42 is provided with a connecting hole 43, and the inner surface of the connecting pipe 42 is slidably connected with a stopper 45, which stops the A vertical rod 44 is fixedly connected to the inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com