Compound automobile tire

An automobile tire and composite technology, which is applied in tire parts, tire tread/tread pattern, vehicle parts, etc., can solve the problems of tire slippage, reduce tire friction, etc. The effect of good compressive impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

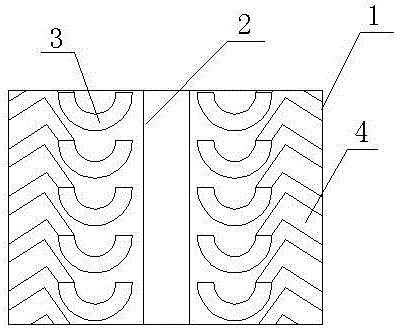

[0014] See figure 1 , a composite tire, including a tread 1 and a pattern block arranged on the tread 1, the pattern block includes a central pattern block 2, side pattern blocks 3 arranged on both sides of the central pattern block 1 and set on the side pattern blocks The shoulder pattern block 4 at the outer end of the block 3, the central pattern block 2 is a strip-shaped bump arranged longitudinally along the tread 1, the side pattern block 3 includes a row of semicircular annular pattern blocks arranged longitudinally, and the shoulder pattern block 4 includes a A row of L-shaped blocks arranged longitudinally, the inner end of the shoulder block 4 is connected to the outer end of the side block 3, the width of the inner end of the shoulder block 4 is equal to the width of the side block 3, the shoulder The width of the outer end of the block 4 is greater than the width of the inner end thereof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com