A drilling tool

A cutting tool and drilling technology, which is applied in the manufacture of tools, drilling tool accessories, metal processing equipment, etc., can solve the problems of difficult to guarantee cutting accuracy, reduce manufacturing cost, and affect the cutting performance of tools, so as to improve the circumferential rigidity and reduce the Effect of cutting vibration and increasing drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

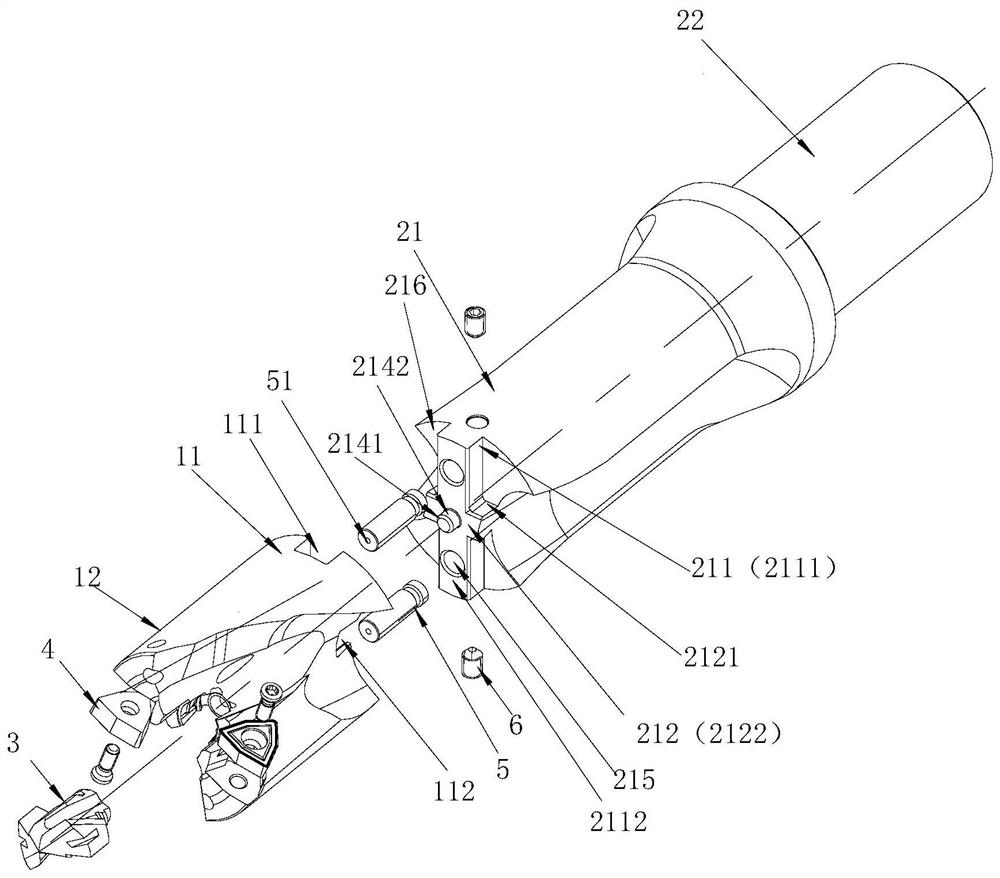

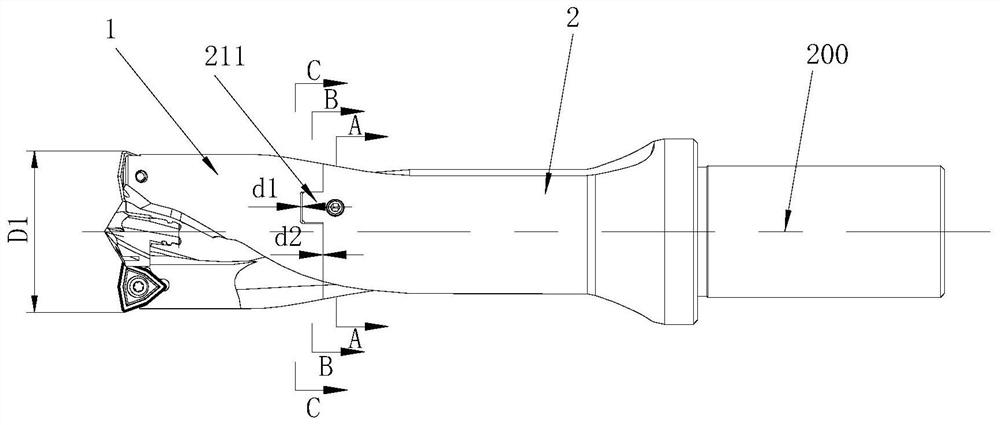

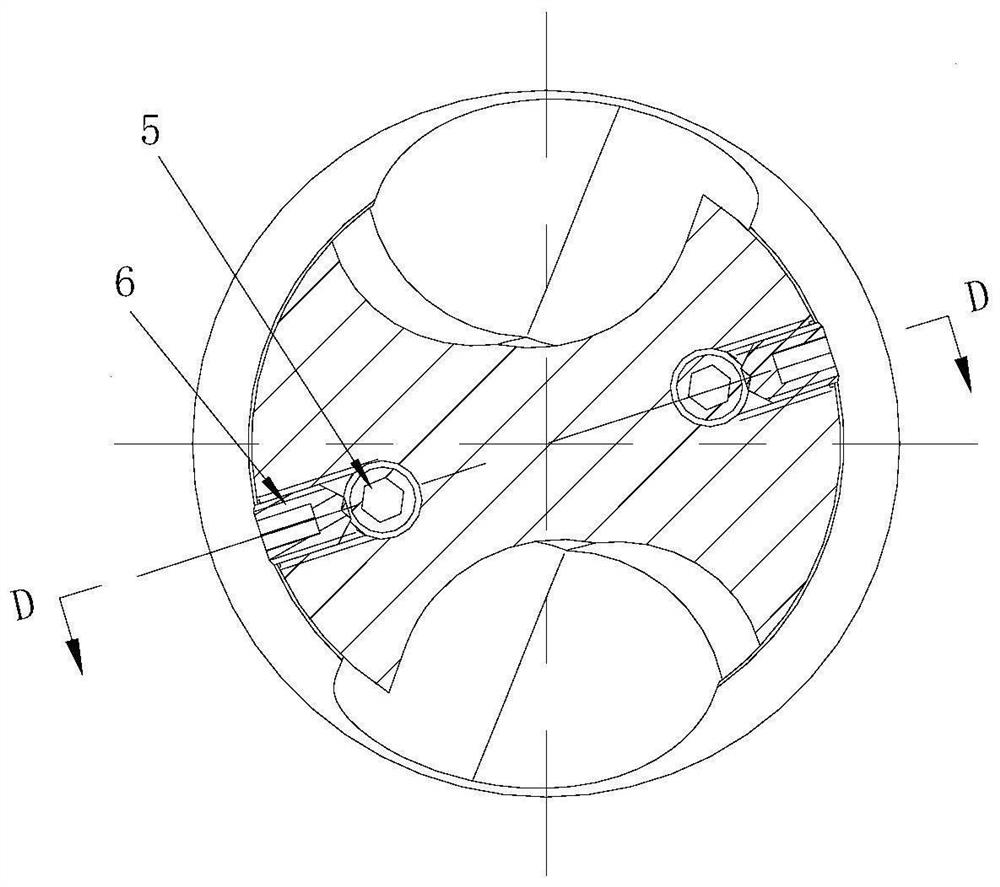

[0034] Figure 1 to Figure 8 An embodiment of the drilling tool of the present invention is shown, the drilling tool includes a cutting part 1, a clamping part 2, a center drill tip 3 and two outer cutting inserts 4, and the cutting part 1 is provided with a cutting interface The clamping part 11 and the cutting part 12, the clamping part 2 is provided with a clamping interface part 21 and a clamping part 22, the cutting interface part 11 can be repeatedly attached to and detached from the clamping interface part 21, the center drill tip 3 and the outer cutting insert 4 are respectively installed At the central and circumferential positions on the cutting portion 12, two outer cutting inserts 4 are respectively arranged on both sides of the central drill tip 3 to form a complete cutting unit with the central drill tip 3, and the cutting i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com