A pile machine with the function of following and supporting the drill pipe

A technology of pile machinery and drill pipe, which is applied in the field of pile machinery with the function of following and supporting the drill pipe, which can solve the problems of high cost, damage to the drill pipe, unfavorable energy saving and environmental protection, etc., and achieve the improvement of drilling depth and high construction accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing. The description in this part is only exemplary and explanatory, and the present invention can be implemented in many different ways defined and covered by the claims, which should not have any limiting effect on the protection scope of the present invention.

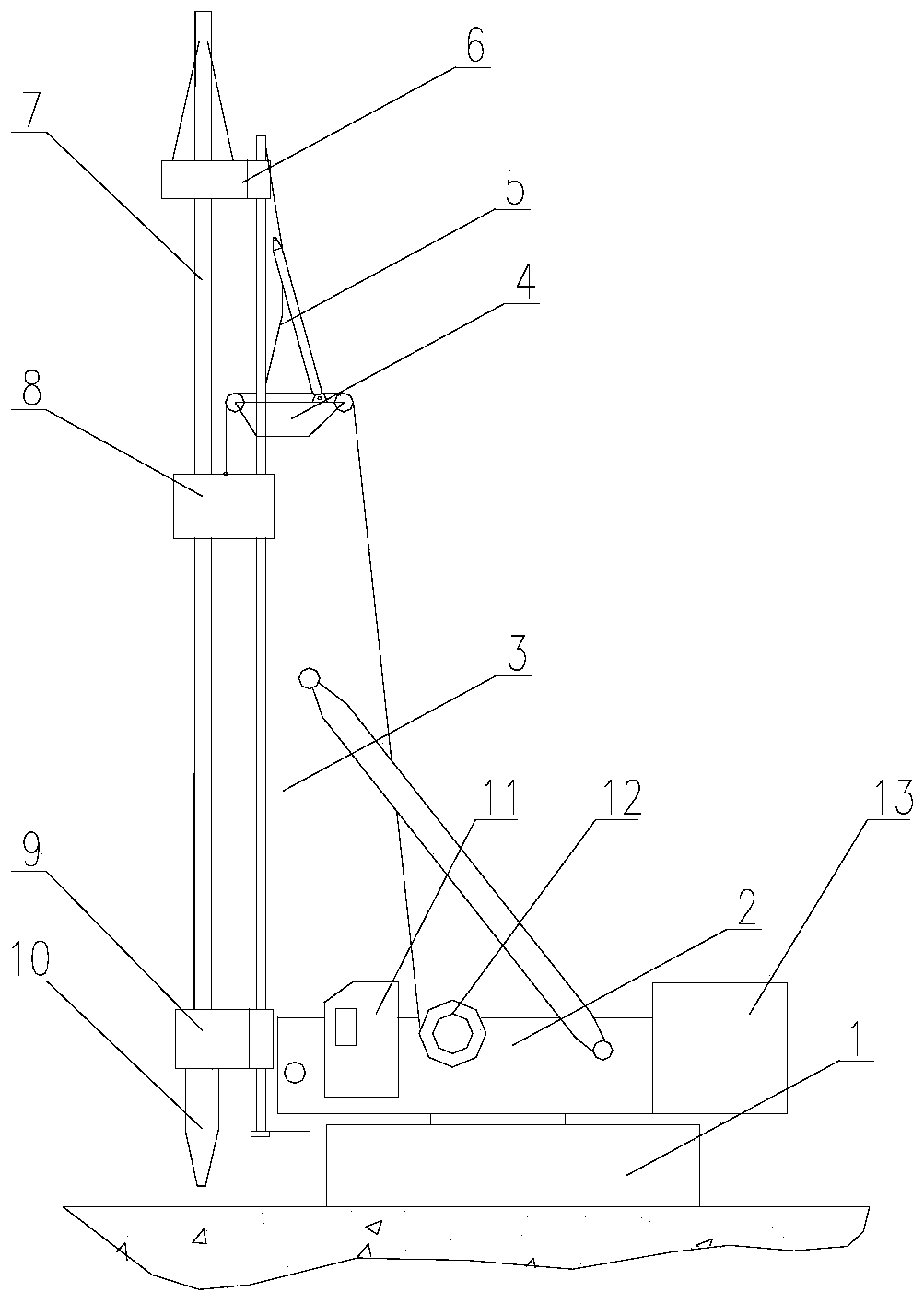

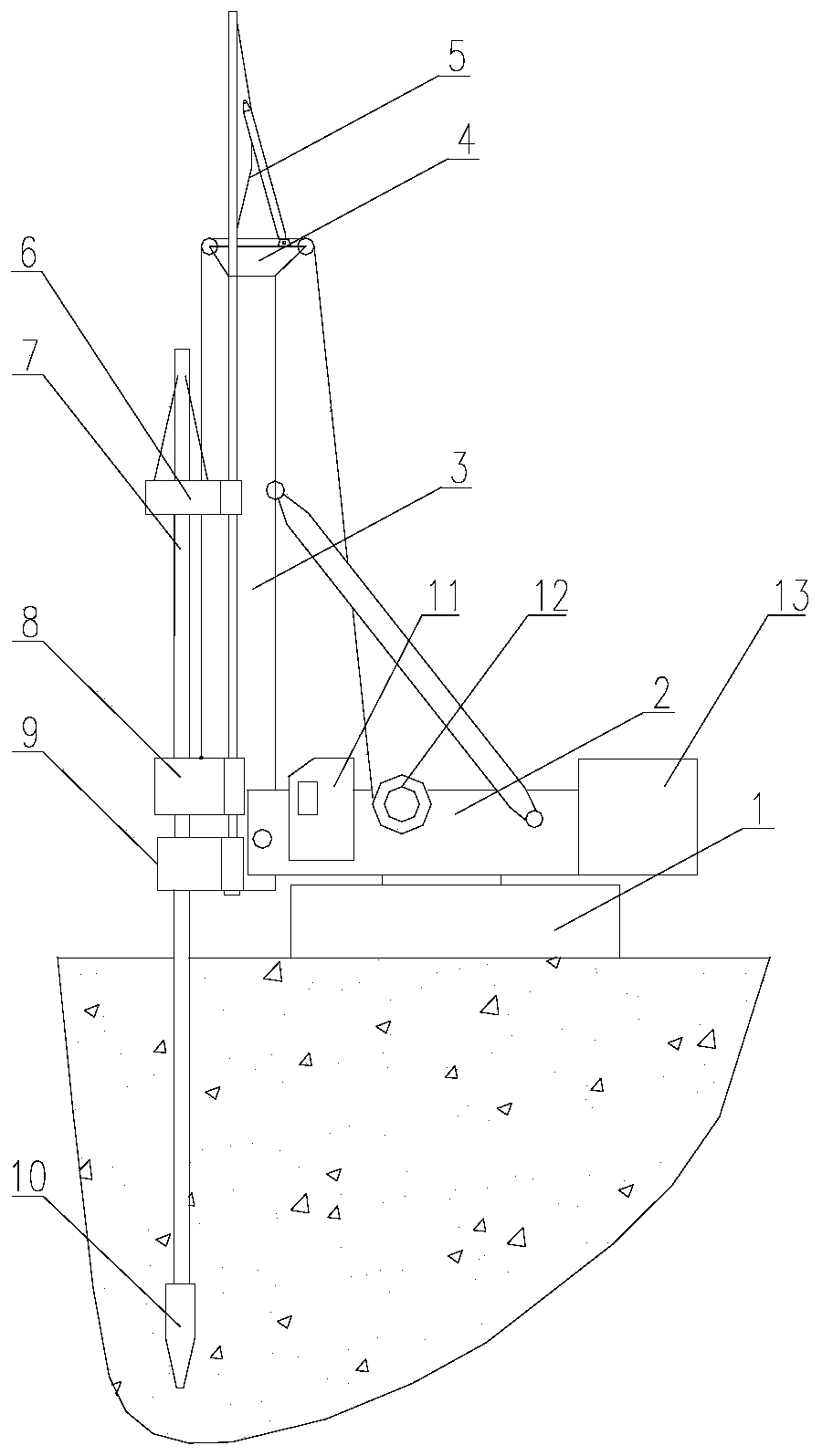

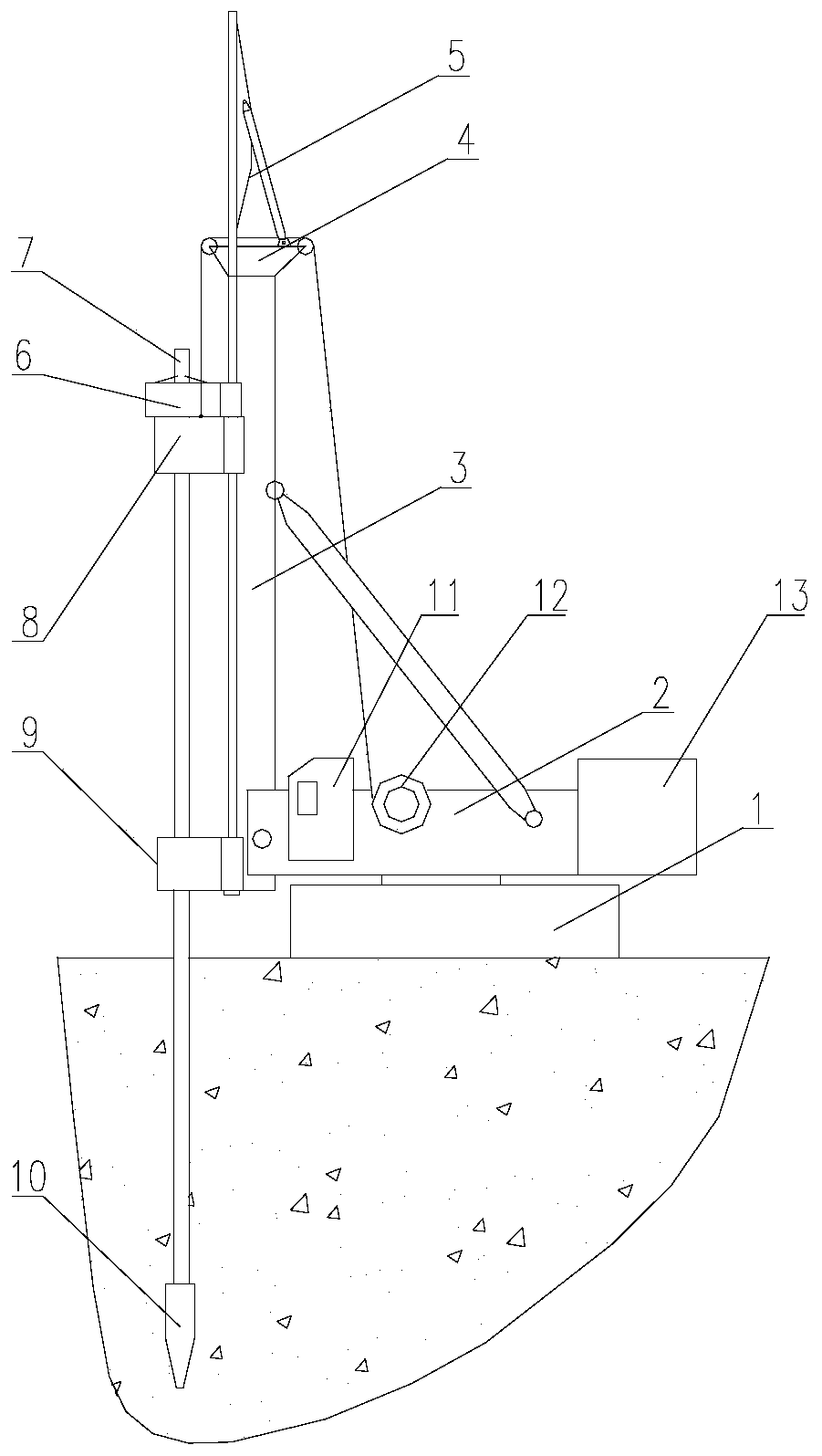

[0024] A specific structure of the present invention is composed of a chassis 1, a fuselage 2, a drill mast 3, a goose head 4, a top bracket 5, a follower supporter 6, a drill pipe 7, a lifting device 8, a lower clamping guide mechanism 9, and a milling head 10. , winch system 11, power system 12, control system 13, etc., see attached figure 1 .

[0025] The lower part of the drill mast 3 is hingedly supported on the front of the fuselage 2, and the goose head 4 is located on the top of the drill mast 3 and is connected with the drill mast 3 by bolts through a circular flange. And the top bracket 5 is located at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com