Cigarette inner package and manufacturing method thereof

A manufacturing method and inner packaging technology, which are applied in the directions of packaging recycling, cigarette packaging, and paper cigarette manufacturing, etc., can solve the problems such as the ineffectiveness of flavor additives, loss of cigarette cut tobacco moisture, and shortening of the storage period of cigarettes, so as to promote convenience and guarantee Stiffness and aesthetics, the effect of avoiding the emission of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

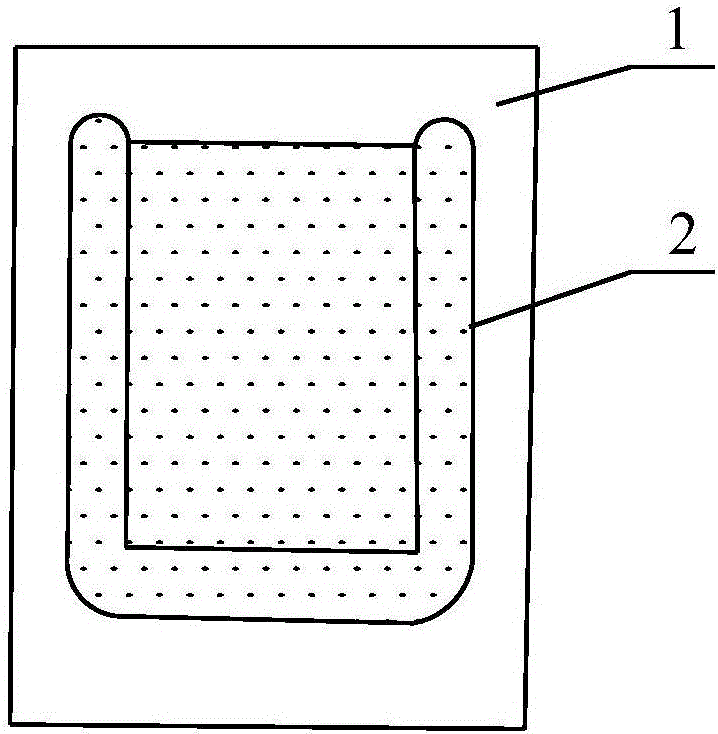

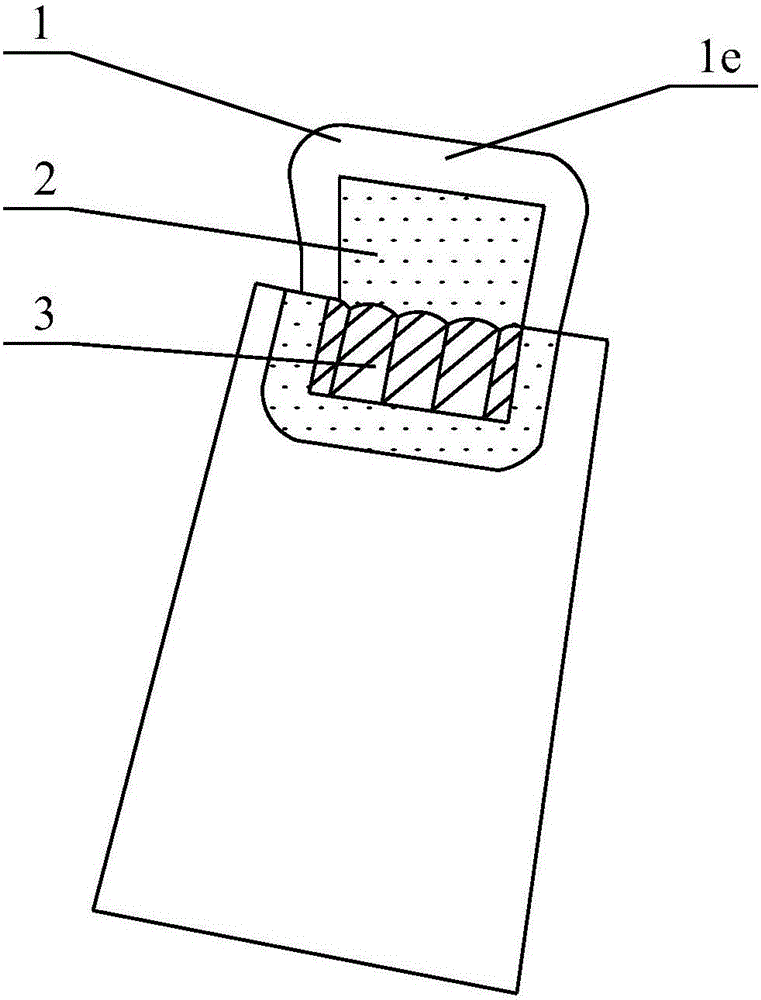

[0031] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a cigarette inner package, the cigarette inner package includes a sealing film 1 and a re-stickable label 2, the sealing film 1 includes an outer film layer 1a, a first composite adhesive layer 1b, and an intermediate film layer 1c , the second composite adhesive layer 1d and the inner film layer 1e, the outer film layer 1a is a polypropylene film layer, the middle film layer 1c is an aluminized layer, the inner film layer 1e is a polypropylene film layer or a paper substrate layer, and the outer film layer Layer 1a is connected to the middle film layer 1c through the first composite adhesive layer 1b, the middle film layer 1c is connected to the inner film layer 1e through the second composite adhesive layer 1d, and the re-stickable label 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com