Combined suspended monorail traffic track beam and its processing technology

A technology for suspending monorails and track beams, which is applied in the field of rail transit, and can solve the problems of difficulty in construction, transportation and on-site installation, large cutting and cutting loss of stiffening plates, and increased cutting and cutting losses of stiffeners, so as to reduce secondary processing and welding The effect of reducing the amount of work, improving the efficiency of processing and manufacturing, and reducing the amount of steel used in the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

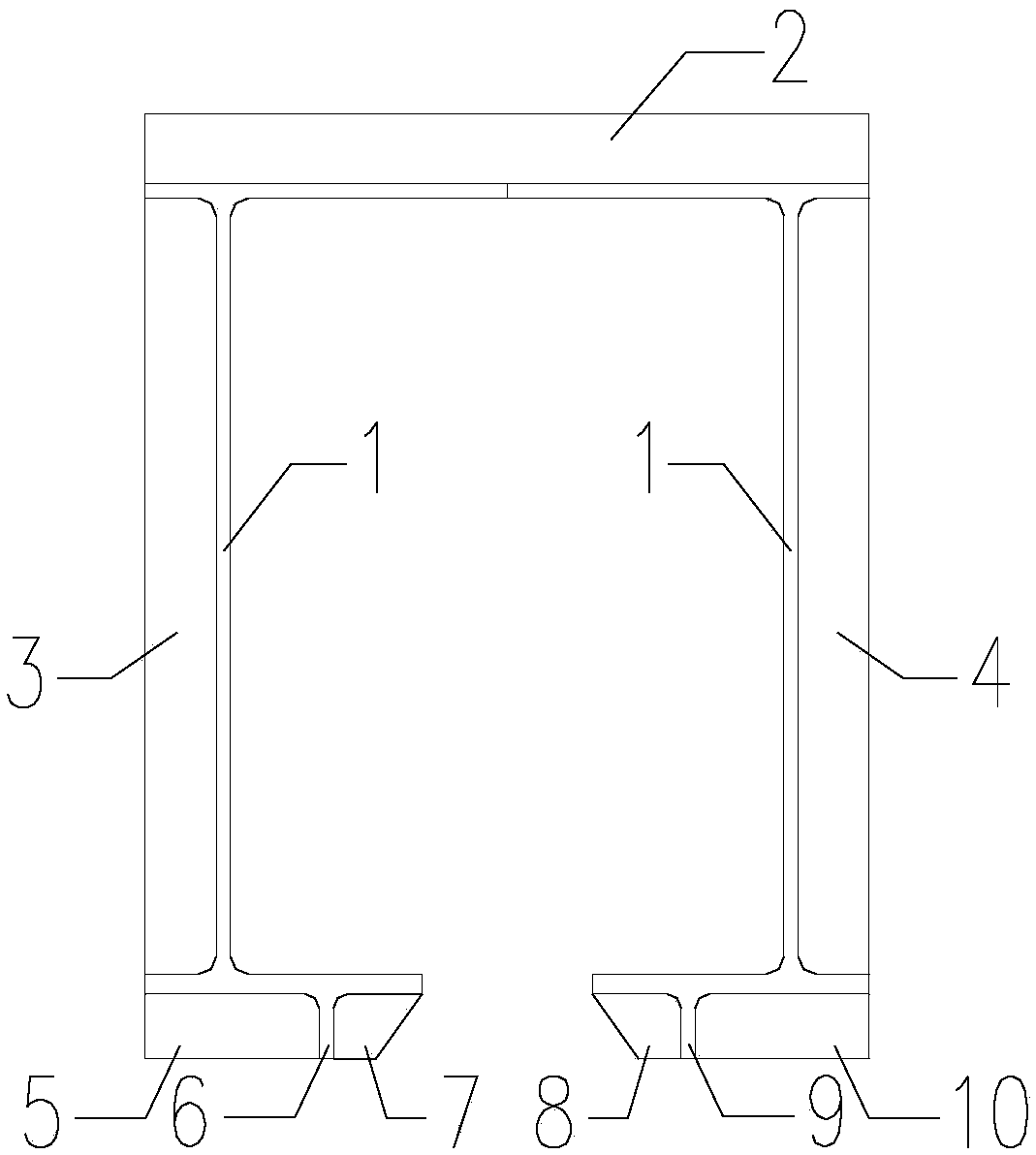

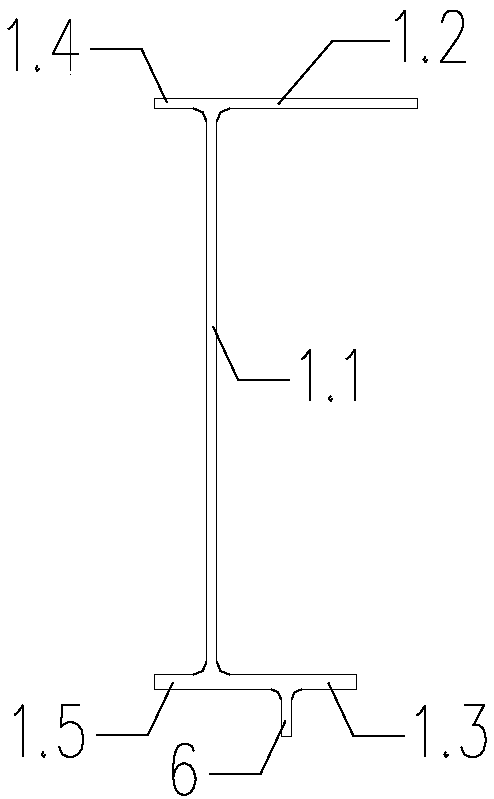

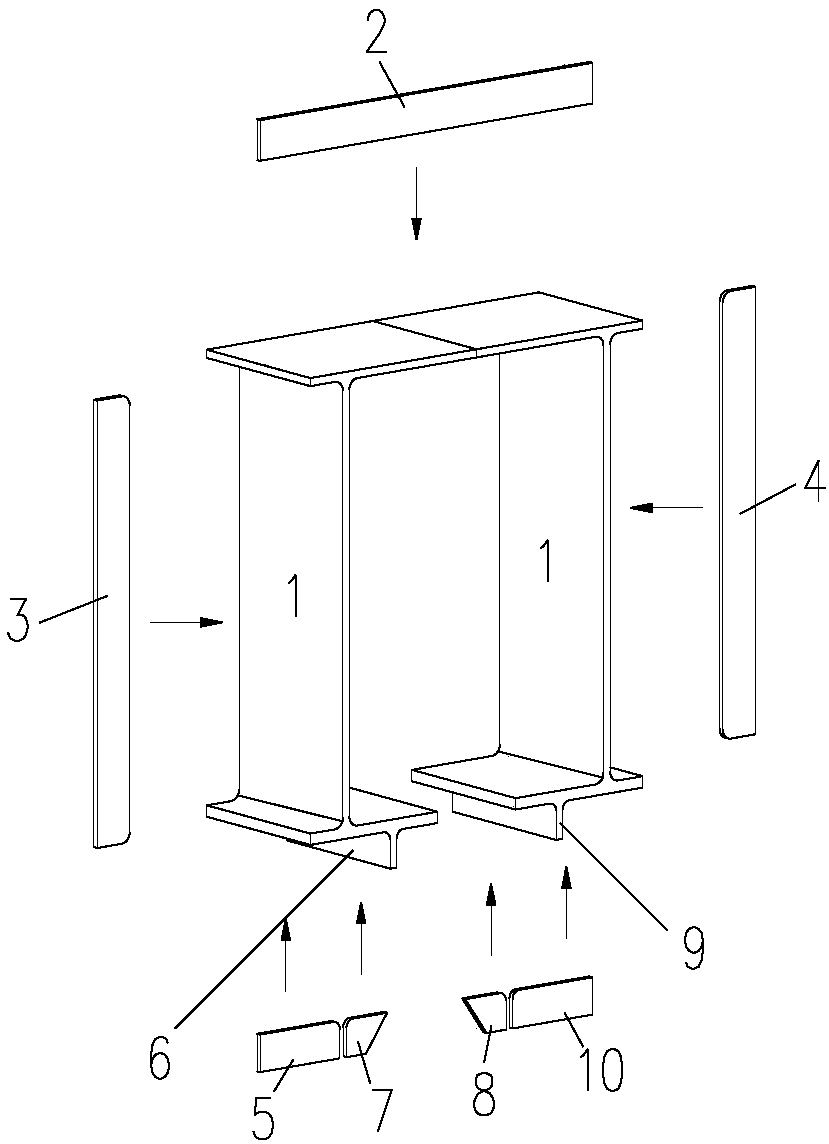

[0058] like Figure 1 to Figure 5 As shown, the combined suspended monorail traffic track beam includes a first track beam main body and a second track beam main body, and the first track beam main body and the second track beam main body are combined into a whole track beam main body 1;

[0059] The first track beam main body and the second track beam main body both include a track beam web 1.1, a track beam top inner flange 1.2,

[0060] The inner flange 1.3 at the bottom of the track beam and the outer flange 1.5 at the bottom of the track beam;

[0061] Both the first track beam main body and the second track beam main body are formed by rolling.

[0062] Preferably, the first track beam main body is provided with a first track beam top outer flange 1.4, and the first track beam main body and the first track beam top outer flange 1.4 are integrally rolled; the second track beam The main body is provided with a second track beam top outer flange 1.4, and the second track ...

Embodiment 2

[0081] like Figure 6 ~ Figure 10 As shown, the combined suspended monorail traffic track beam includes a first track beam main body and a second track beam main body, and the first track beam main body and the second track beam main body are combined into a whole track beam main body 1;

[0082] The first track beam main body and the second track beam main body both include a track beam web 1.1, a track beam top inner flange 1.2,

[0083] The inner flange 1.3 at the bottom of the track beam and the outer flange 1.5 at the bottom of the track beam;

[0084] Both the first track beam main body and the second track beam main body are formed by rolling.

[0085] Preferably, the first track beam main body is provided with a first track beam top outer flange 1.4, and the first track beam main body and the first track beam top outer flange 1.4 are integrally rolled and formed; the second track beam The main body is provided with a second track beam top outer flange 1.4, and the se...

Embodiment 3

[0104] like Figure 11 to Figure 15 As shown, the combined suspended monorail traffic track beam includes a first track beam main body and a second track beam main body, and the first track beam main body and the second track beam main body are combined into a whole track beam main body 1;

[0105] The first track beam main body and the second track beam main body both include a track beam web 1.1, a track beam top inner flange 1.2,

[0106] The inner flange 1.3 at the bottom of the track beam and the outer flange 1.5 at the bottom of the track beam;

[0107] Both the first track beam main body and the second track beam main body are formed by rolling.

[0108] Preferably, the first track beam main body and the second track beam main body are welded.

[0109] Preferably, the first track beam main body and the second track beam main body are mirror images.

[0110] Preferably, the bottom of the first track beam main body is provided with a first bottom full-length stiffener 6;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com