A process and device for preventing water hammer in LNG pipelines

A process method and water hammer technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of inapplicability, and achieve the effects of easy processing, reasonable design and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Configuration device:

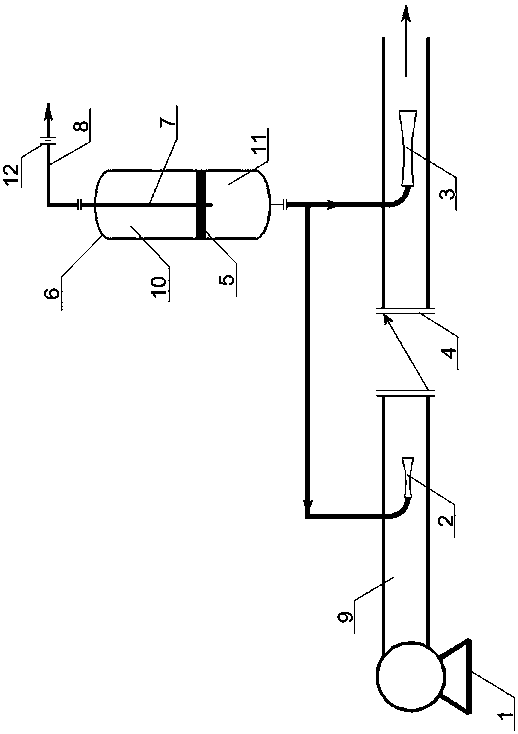

[0021] The device for preventing water hammer in LNG pipelines includes an LNG pump 1 and a buffer tank 6, a check valve 4 is installed in the middle of the outlet pipeline 9 of the LNG pump 1, and the outlet pipeline 9 on the upstream side of the check valve 4 is Injector 1 2 is arranged inside, and injector 2 3 is arranged in the outlet pipeline 9 of the downstream part on the other side of check valve 4; the nozzle direction of injector 1 2 and injector 2 3 is in line with the normal liquid outlet direction of LNG pump 1 same.

[0022] The outlet pipes at the bottom of the buffer tank 6 communicate with the first injector 2 and the second injector 3 respectively, and the top of the buffer tank 6 communicates with the cold preservation circulation pipeline 8 on which a flow-restricting orifice 12 is arranged. The inside of the buffer tank 6 is radially equipped with a separation plate 5, and the inner cavity of the buffer tank 6 at the top of ...

Embodiment 2

[0025] Configuration device:

[0026] The device for preventing water hammer in LNG pipelines includes an LNG pump 1 and a buffer tank 6, a check valve 4 is installed in the middle of the outlet pipeline 9 of the LNG pump 1, and the outlet pipeline 9 on the upstream side of the check valve 4 is Injector 1 2 is arranged inside, and injector 2 3 is arranged in the outlet pipeline 9 of the downstream part on the other side of check valve 4; the nozzle direction of injector 1 2 and injector 2 3 is in line with the normal liquid outlet direction of LNG pump 1 same.

[0027] The outlet pipes at the bottom of the buffer tank 6 communicate with the first injector 2 and the second injector 3 respectively, and the top of the buffer tank 6 communicates with the cold preservation circulation pipeline 8 on which a flow-restricting orifice 12 is arranged. The inside of the buffer tank 6 is radially equipped with a separation plate 5, and the inner cavity of the buffer tank 6 at the top of ...

Embodiment 3

[0030] Configuration device:

[0031] The device for preventing water hammer in the LNG pipeline includes an LNG pump 1 and a buffer tank 6, a check valve 4 is installed in the middle of the outlet pipeline 9 of the LNG pump 1, and the outlet pipeline 9 on the upstream side of the check valve 4 is Injector 1 2 is arranged inside, and injector 2 3 is arranged in the outlet pipeline 9 of the downstream part on the other side of check valve 4; the nozzle direction of injector 1 2 and injector 2 3 is in line with the normal liquid outlet direction of LNG pump 1 same.

[0032] The outlet pipes at the bottom of the buffer tank 6 communicate with the first injector 2 and the second injector 3 respectively, and the top of the buffer tank 6 communicates with the cold preservation circulation pipeline 8 on which a flow-restricting orifice 12 is arranged. The inside of the buffer tank 6 is radially equipped with an isolation plate 5, and the inner cavity of the buffer tank 6 at the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com