Field winding type magnetic flux sensor calibration method

A technology of magnetic flux sensor and calibration method, applied in instruments, measuring devices, measuring fluid pressure, etc., to achieve the effect of easy engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

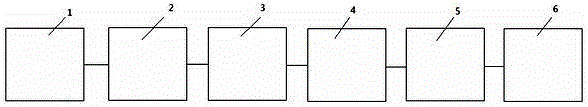

[0017] Attached below figure 1 The present invention is described in detail:

[0018] A field-wound magnetic flux sensor calibration method, the method is as follows: after the sensor is installed and self-tested through link 1, different numbers of load test vehicles are manually added on the bridge or a water load test method is adopted;

[0019] The load simulated by this method is divided into 5 stages to simulate the change of cable force. Among them, 25% load case 2, 50% load case 3, 75% load case 4, and 100% load case 5. After the load simulation of the stage, perform calibration and fitting to obtain the fitting coefficient K6 of the force value-measurement value;

[0020] After carrying out the load simulation at different stages, the data of the load value and the measured value are obtained, and the quadratic term fitting is carried out according to this, and the calibration coefficient is obtained. In the subsequent measurement, the fitting coefficient K6 can be u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap