Station design mode-based air particulate matter automatic film-changing sampling device

A technology for air particulate matter and automatic film change, applied in sampling devices, measuring devices, sampling, etc., can solve the problems of result deviation and manpower consumption, and achieve the effects of continuous improvement, convenience and consistency, and reduction of manpower output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

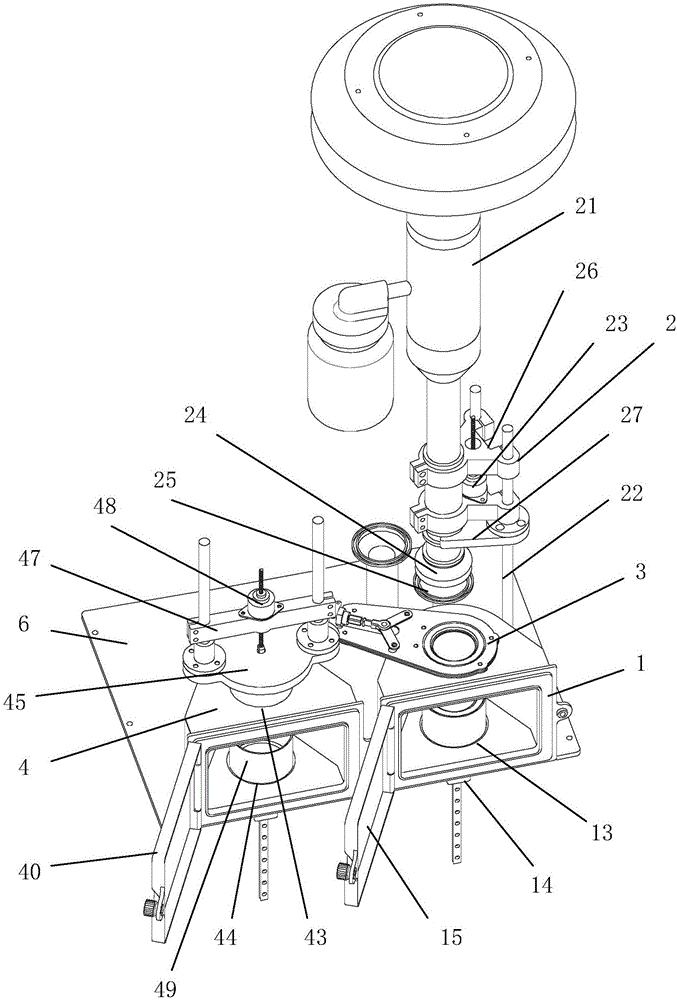

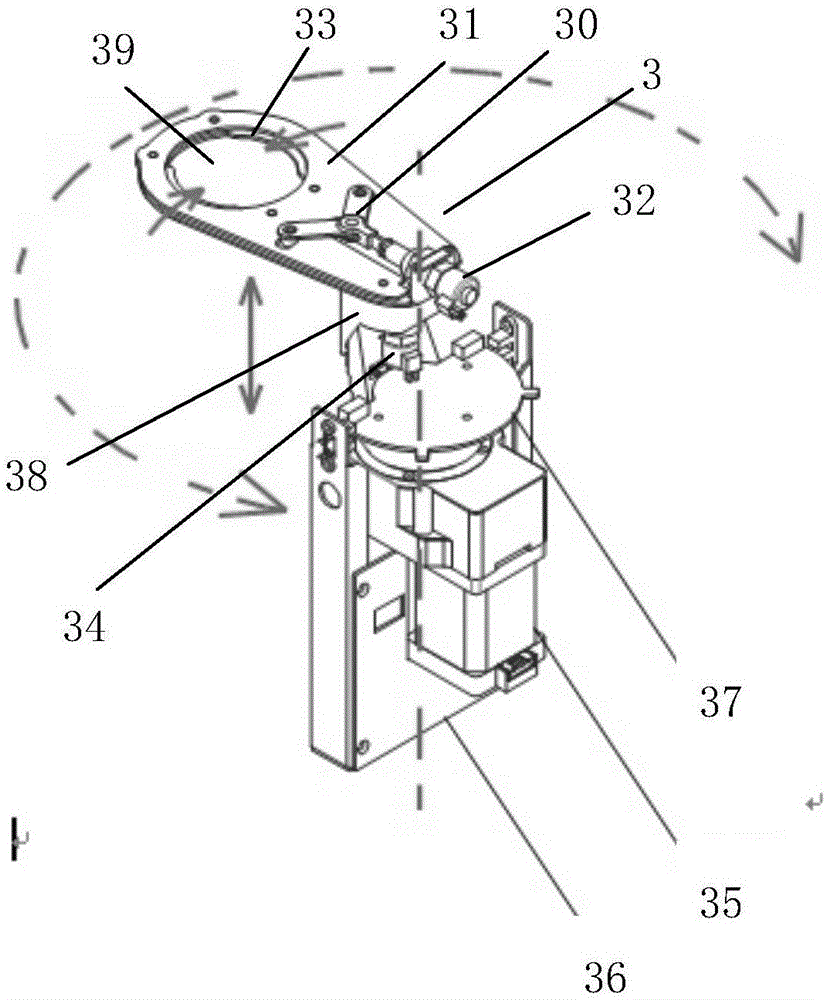

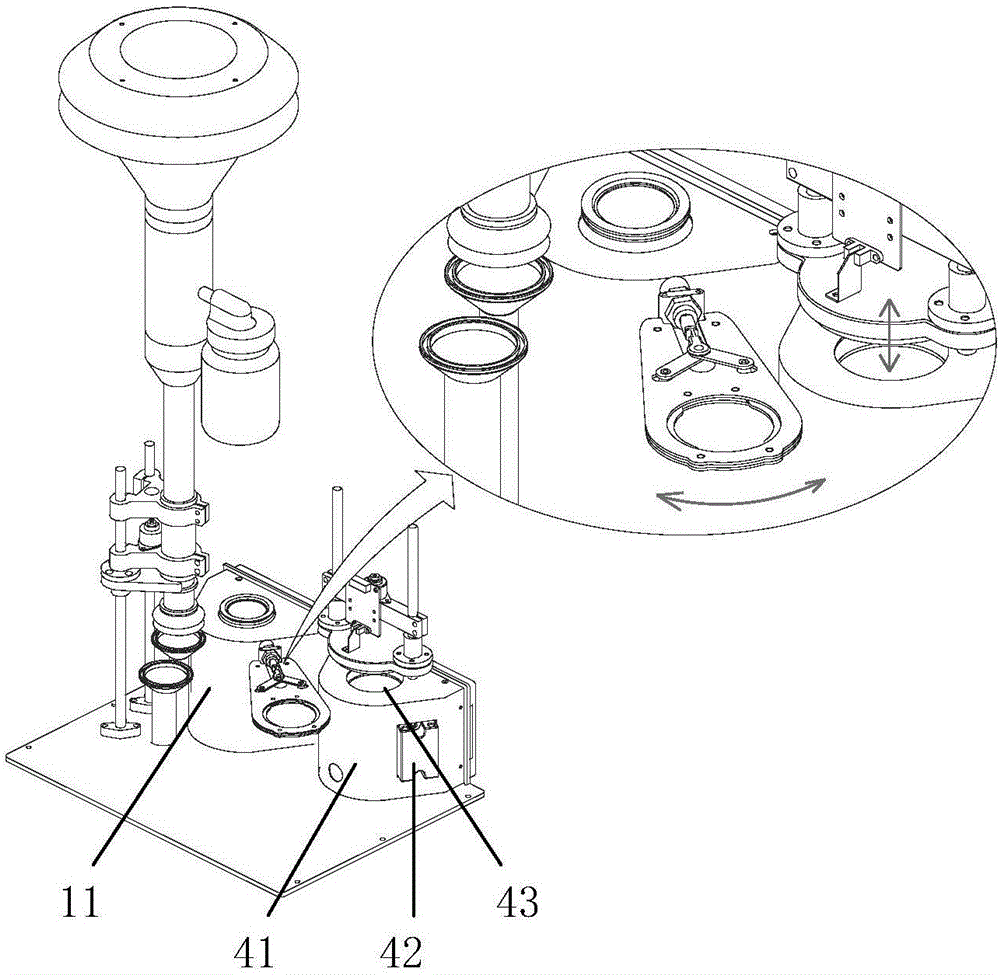

[0024] Such as Figure 1-Figure 7 As shown, an air particle automatic membrane-changing sampler device based on station design includes a membrane loading mechanism 1 , a collection mechanism 2 , a manipulator 3 , a storage mechanism 4 and a filter membrane jacket 5 .

[0025] Such as figure 1 As shown, the upper membrane mechanism 1 is fixed on the support plate 6, the upper membrane mechanism includes an upper membrane box 11, and the upper and lower parts of the upper membrane box are respectively provided with an upper membrane through hole 12 and an upper membrane. Lower through hole 13, such as Figure 4 and Figure 5 As shown, the filter membrane jacket 5 is placed in the through hole under the upper membrane, and the filter membrane jacket includes a filter membrane clamp 51 and a membrane car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com