Nursing bottle component and nursing bottle

A feeding bottle and component technology, applied to feeding bottles, internal accessories, etc., to achieve the effect of wide milk powder falling channel and fast milk powder release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

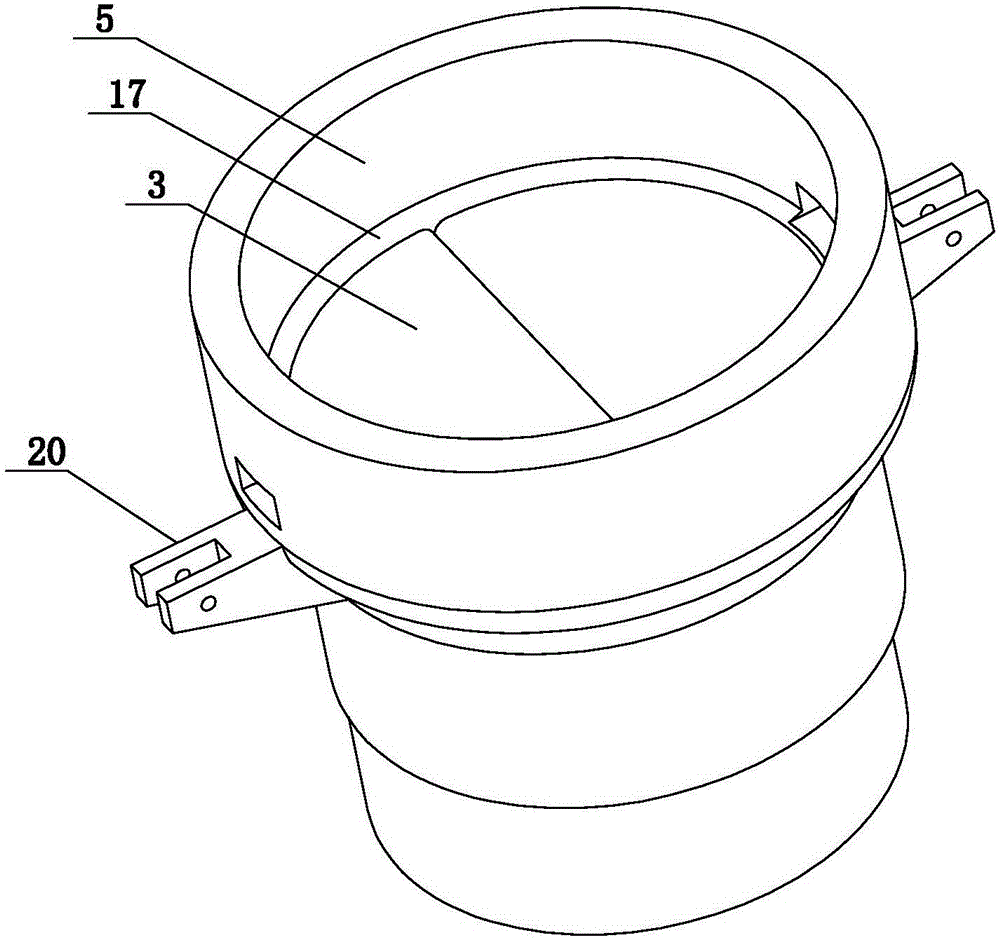

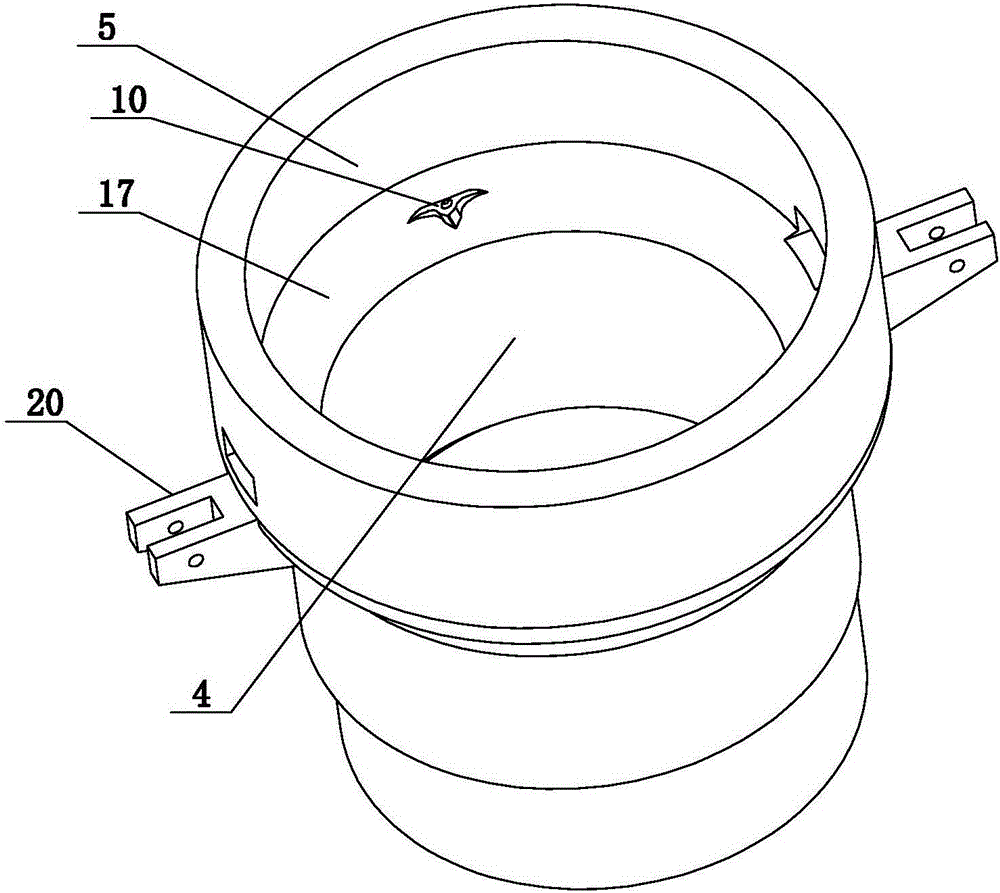

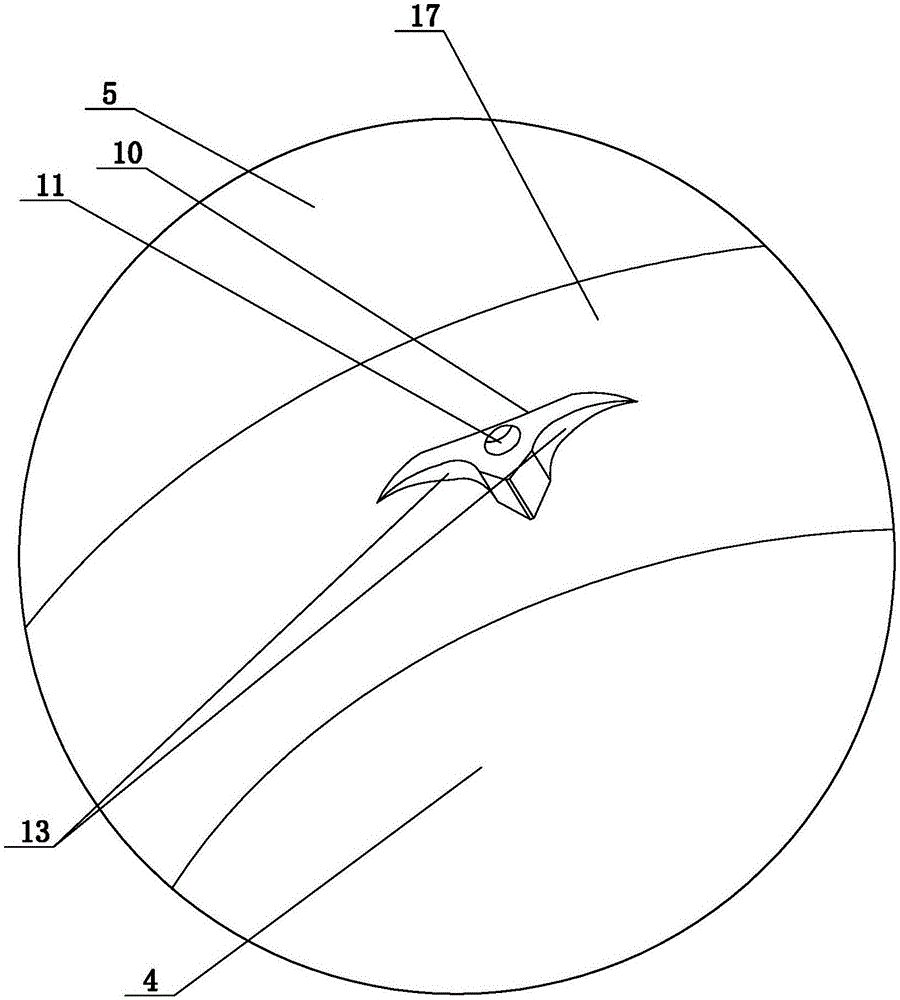

[0040] Embodiment one, such as Figure 1 to Figure 6 ,as well as Figure 17 , 18 shown.

[0041] A feeding bottle assembly, which includes a powder storage box with openings at both ends. The powder storage box is provided with a barrier piece 3 that can be folded and folded in half. Parts are respectively marked as the first part 4 and the second part 5, and the barrier sheet 3 is connected with a control mechanism, which is used to control the barrier sheet 3 to be folded and folded toward the second part 5 side to fold the first part 4 and the second part 5 connected.

[0042] The barrier sheet 3 includes a first skeleton 6, a second skeleton 7, and a third skeleton 8. The folded and folded state of the barrier sheet 3 is set as an initial state. In this initial state, the first skeleton 6, the second skeleton 7, and the third skeleton 8 It is distributed in an inverted U shape, wherein the first skeleton 6 and the third skeleton 8 are vertically arranged side by side, ...

Embodiment 2

[0052] Embodiment two, such as Figure 7 , 8 shown.

[0053] A feeding bottle, which includes a nipple 1 and a bottle body, characterized in that the bottle body at least includes two parts, the first section 2.1 and the second section 2.2 distributed up and down, the first section 2.1 and the second section 2.2 are detachably connected, That is threaded connection; the first paragraph 2.1 is the powder storage box.

[0054] The powder storage box adopted in the second embodiment is the structure of the first embodiment.

[0055] The recovery process of the barrier sheet 3 is to remove the second part 2.2 to expose the lower end of the first part 2.1, then the barrier sheet 3 is unfolded, and the telescopic rod 18 is reset and supported, that is, the reset of the entire barrier sheet 3 is completed.

Embodiment 3

[0056] Embodiment three, such as Figure 9 , 10 shown.

[0057] A feeding bottle comprises a nipple 1 and a bottle body 2, one end of a powder storage box is detachably connected to the nipple 1 of the feeding bottle, and the other end of the powder storage box is detachably connected to the bottle body 2 of the feeding bottle.

[0058] Generally speaking, in existing conventional feeding bottles, the part of the nipple 1 that is used to connect the bottle body 2 is provided with an internal thread, and the part of the bottle body 2 that is used to connect the nipple 1 is set as an external thread. Therefore, the upper end of the powder storage box is set as External thread, the lower end of the powder storage box is set as internal thread, so as to match the structure of the existing feeding bottle.

[0059] In order to control the axial length of the powder storage box and to obtain a large milk powder storage capacity, the diameter of the powder storage box is relatively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com