Suspension type ultrasonic atomization generator and humidifier

A technology of ultrasonic atomization and generator, applied in the direction of air humidification system, heating method, lighting and heating equipment, etc., can solve the problems of unmaintainable, difficult maintenance, harsh use conditions, etc., achieve simple structure, convenient use, and get rid of dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

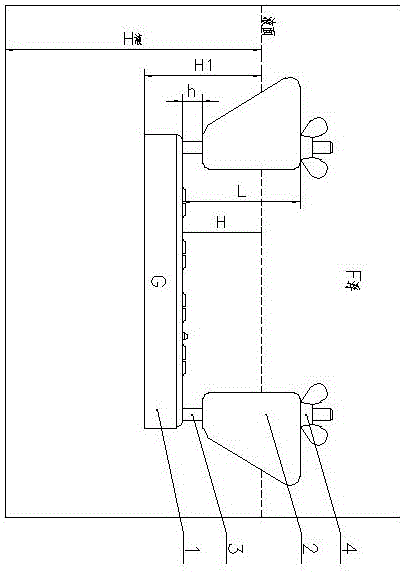

[0048] Example 1, see figure 1 , install connectors at both ends of the body of the ultrasonic atomization generator, the connectors are round rods with threads at one end, one end of the connectors is fixedly connected with the body of the ultrasonic atomizer, and then the floating bodies are respectively set on the connectors Then install the wing nuts on the connecting piece respectively, the wing nut adjusts the position of the floating body on the connecting piece, the distance from the highest point of the floating body to the working surface of the ultrasonic atomizing generator is greater than the normal working distance of the ultrasonic atomizing generator The depth of the liquid level, the total buoyancy is greater than the total gravity, the bottom of the floating body is small, and the top is large, which is conducive to the balance and stability of the suspended ultrasonic atomization generator; the wing nut may be replaced by an ordinary nut.

Embodiment 2

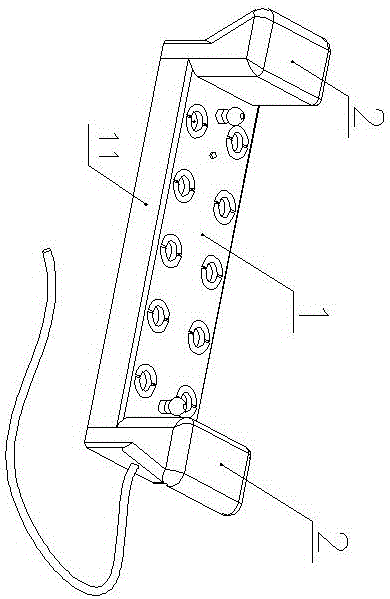

[0049] Example 2, see figure 2 , on the shell of the ultrasonic atomizing generator body, two floating bodies are symmetrically arranged left and right. The floating bodies are pasted on the left and right sides of the outer surface of the shell of the ultrasonic atomizing generator body. The distance is greater than the liquid level depth of the normal working of the ultrasonic atomization generator, and the total buoyancy generated by the two floating bodies is greater than the total gravity of the suspension type ultrasonic atomization generator. The balance and stability of the generator.

Embodiment 3

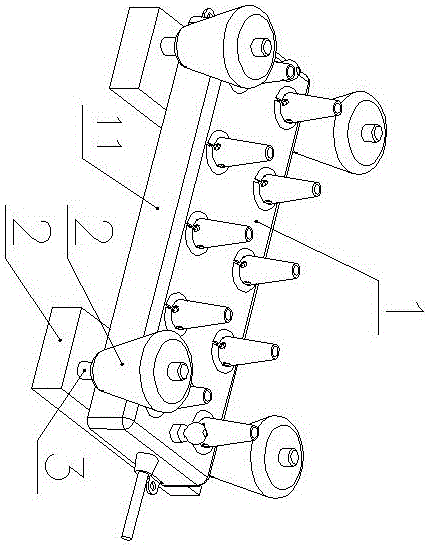

[0050] Example 3, see image 3 , at the bottom of the body of the ultrasonic atomization generator, two floating bodies are symmetrically fixedly installed, and connecting pieces are respectively fixed symmetrically on both sides of the two floating bodies. The connecting piece is a cylindrical rod, and the other end of the cylindrical rod is provided with a screw thread , in addition, on the four cylindrical rods, internally threaded floating bodies are respectively installed. The floating body is a cone with the small end facing down and the large end facing upwards. The floating body can rotate up and down along the thread provided on the cylindrical rod. , the distance from the highest point of the floating body to the working surface of the ultrasonic atomization generator is greater than the liquid level depth of the normal operation of the ultrasonic atomization generator, and the total buoyancy generated by all the floating bodies is greater than the total gravity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com