Sheet metal stamping device

A stamping device and plate technology, applied in the direction of stamping machines, electromechanical devices, presses, etc., can solve the problems of low safety factor, personal injury, etc., and achieve the effects of improving safety, convenient control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

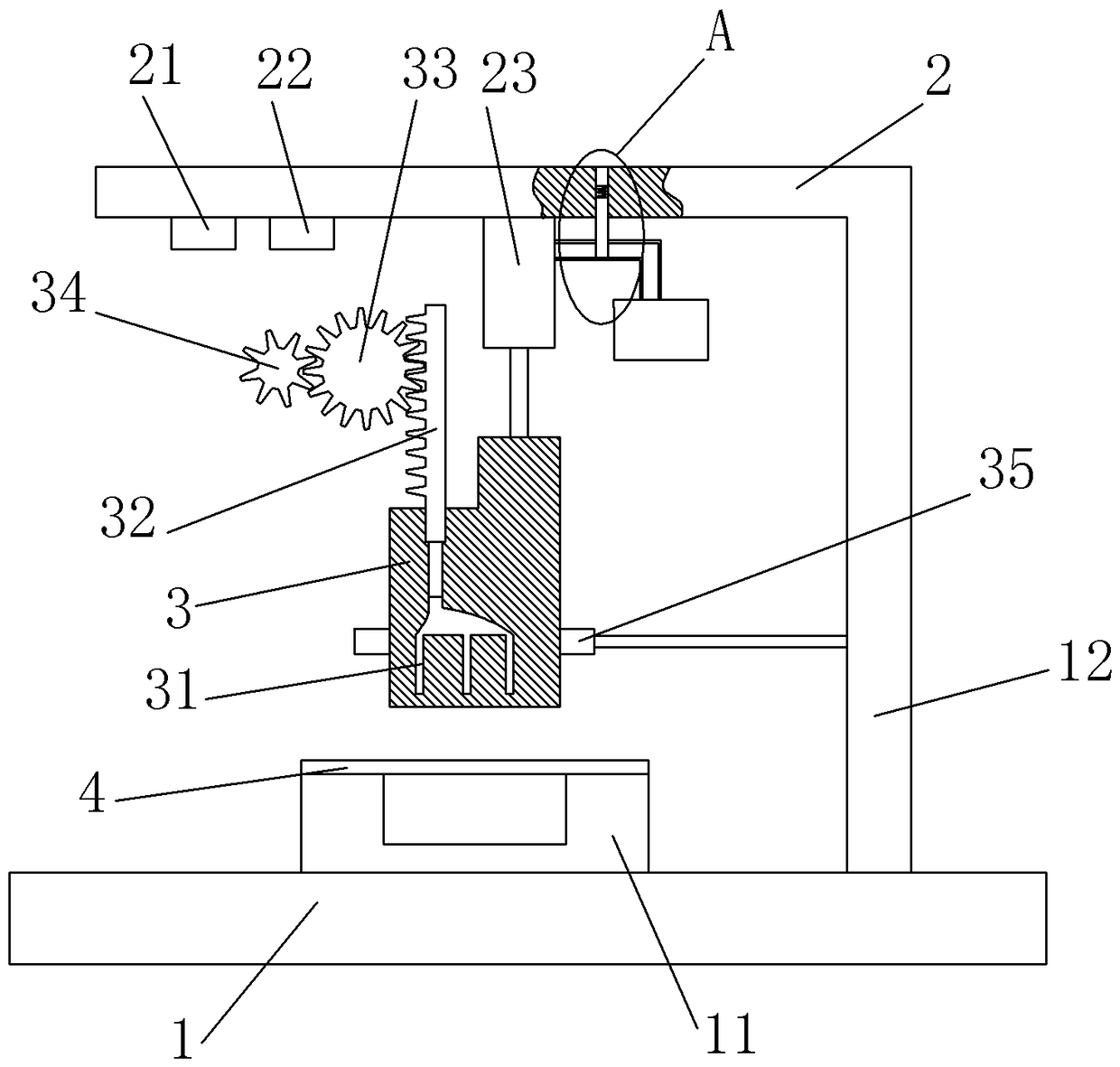

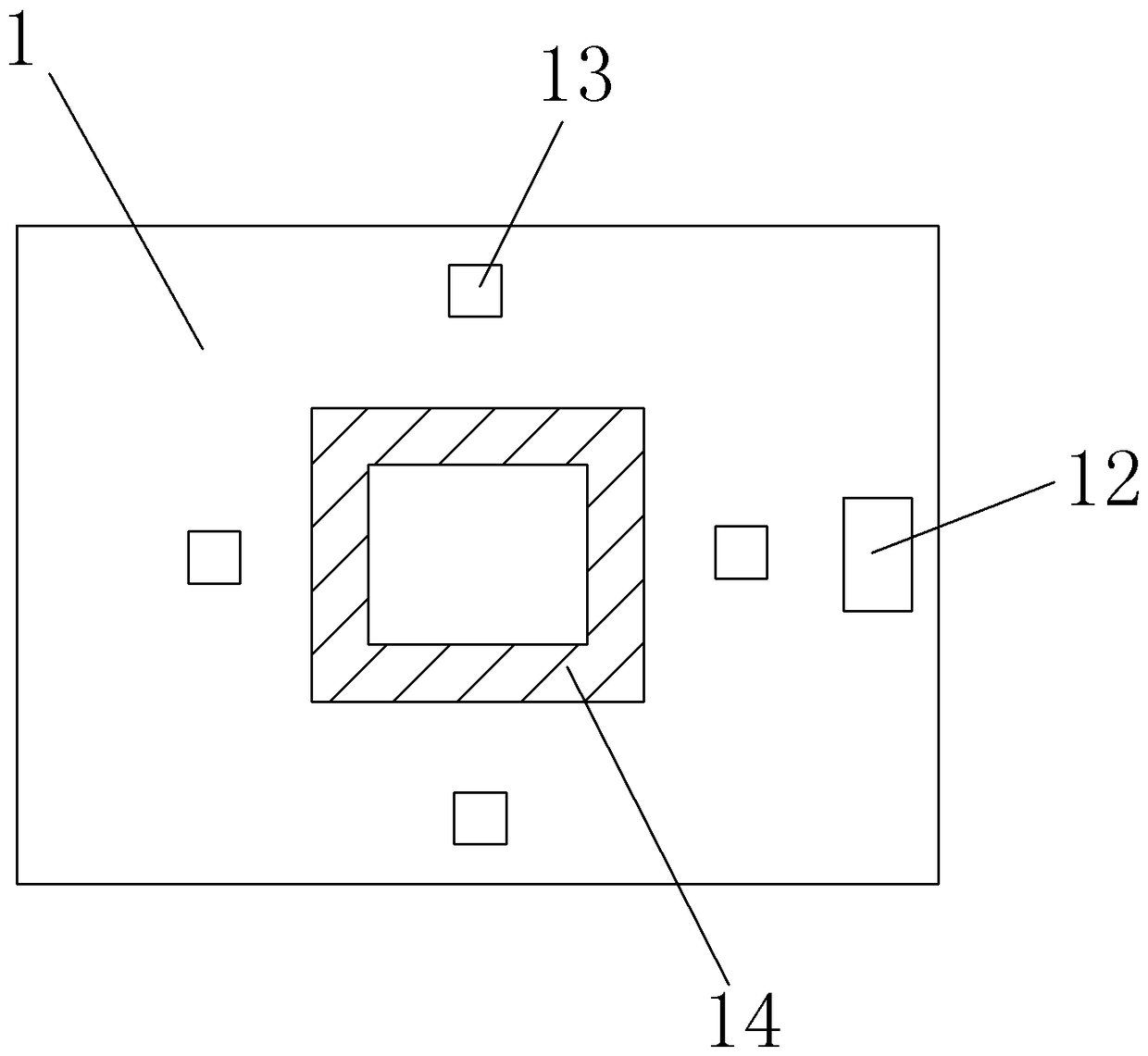

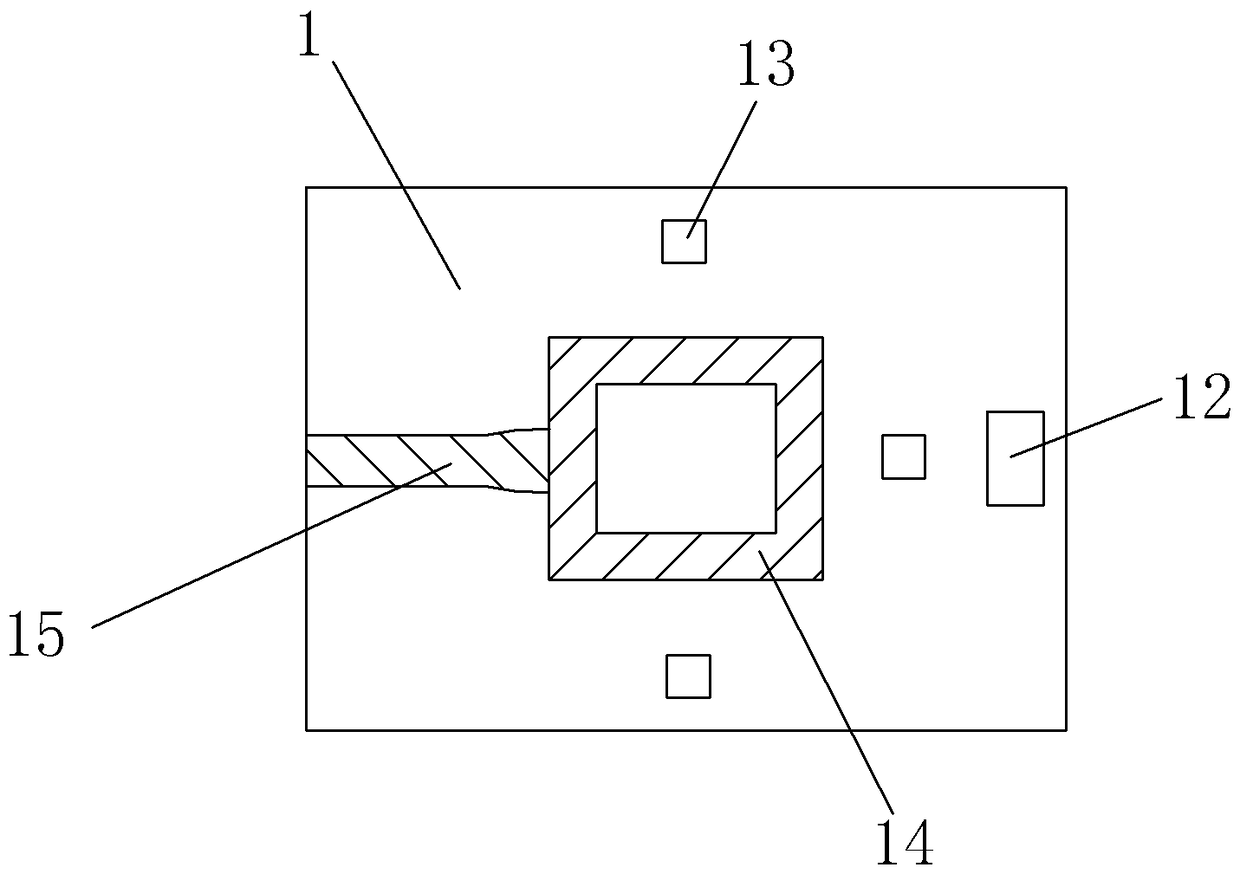

[0024] The reference signs in the accompanying drawings include: base 1, mounting base 11, bracket 12, photoelectric switch 13, safety shadow area 14, hand shadow area 15, mounting frame 2, first storage battery 21, second storage battery 22, cylinder 23 , intake pipe 24, spool 25, electromagnetic block 26, stamping head 3, air collecting tank 31, first rack 32, first gear 33, second gear 34, light source 35, generator 36, plate 4.

[0025] The embodiment is basically as attached figure 1 Shown: the sheet metal stamping device, including a base 1, a mounting seat 11 is arranged on the upper part of the base 1, and a mounting groove is opened on the mounting seat 11, and a stamping die is placed in the mounting groove, and a number of photoelectric devices are distributed on the upper part of the base 1 There are 4 switches 13 and photoelectric switches 13 in total. The 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com