Method for cast-bonding of journal of finished product roller through protective jacket

A technology of protective sleeves and rollers, which is applied in the field of repairing rollers, can solve problems such as the shrinkage of the diameter of the journal, no effective countermeasures, and easy scalding of the rollers, so as to improve operability, improve machining efficiency, The effect of convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is described in further detail:

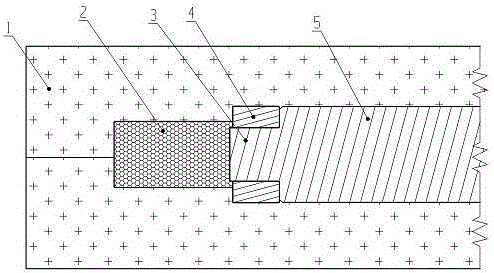

[0032] like figure 1 Shown is a schematic diagram of the structure of each element in the casting process of the present invention. The present invention is a method for casting the journal 3 of the finished roll 5 by using the protective sleeve 4, which mainly includes the following steps:

[0033] Step a: Use a flaw detector to detect flaws on the journal 3 of the roll 5 to determine the depth and position of internal defects in the journal 3 .

[0034] Step b: According to the position of the defect of the journal 3 of the roll 5, cut off and remove the defective part of the journal 3 of the roll 5, and remove the defective part to form a flat end surface of the journal 3.

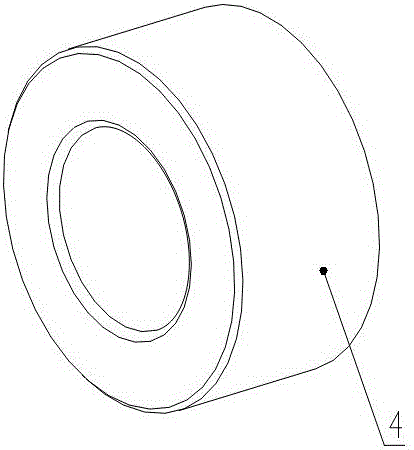

[0035] Step c: making the protective sleeve 4 according to the remaining length of the journal 3 and the diameter of the journal 3, so that the length of the protective sleeve 4 is 5-15mm shorter than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com