A top discharge internal mixer for tablecloth production

An internal mixer and table cloth technology, applied in the field of internal mixers, can solve the problems of difficulty in reclaiming materials for internal mixers, and achieve the effects of improving production efficiency and increasing the speed of material collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described.

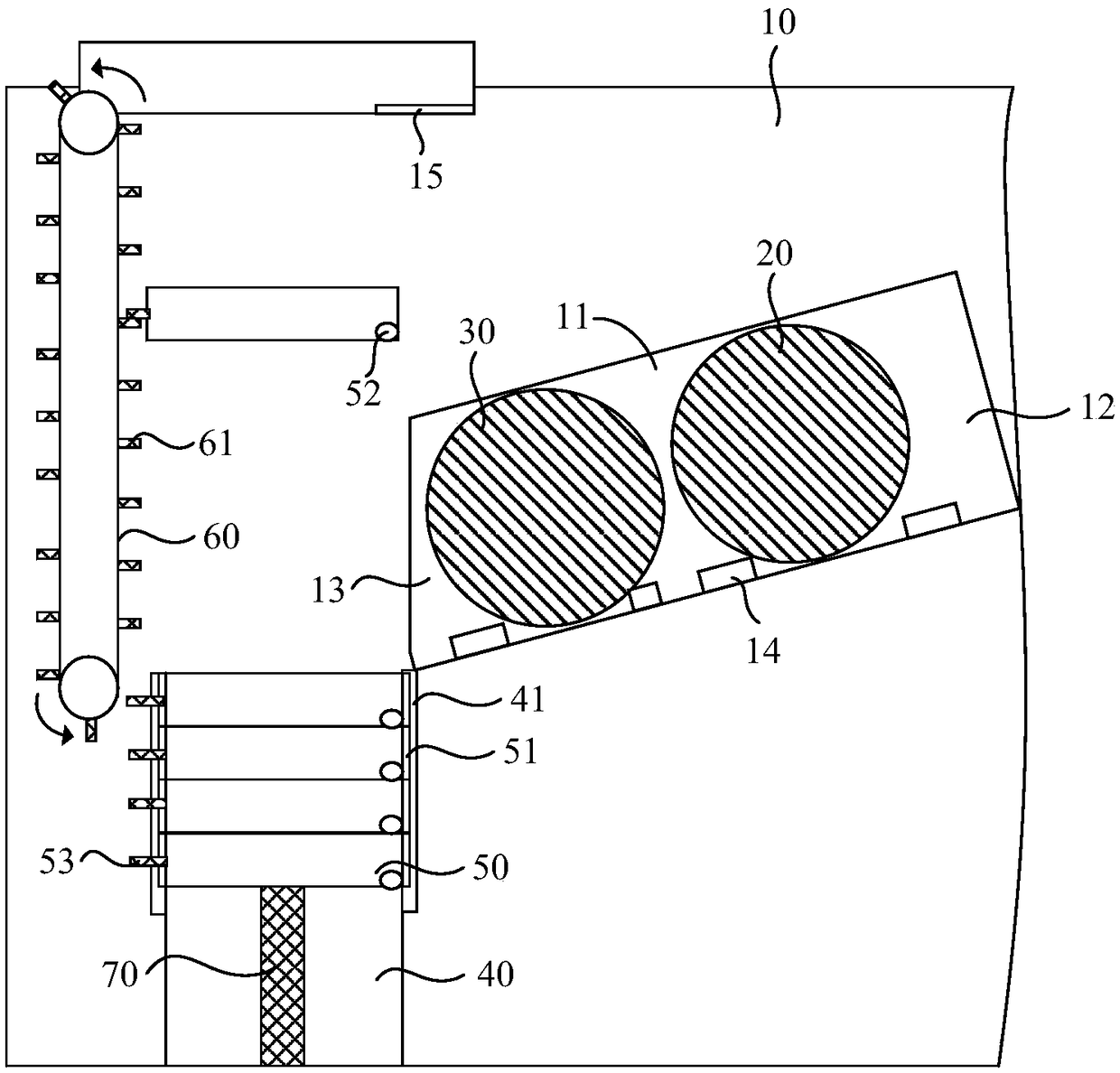

[0021] see figure 1 , figure 1 It is a horizontal structural schematic diagram of an embodiment of a top discharge internal mixer used for tablecloth production according to the present invention. figure 1 The shown internal mixer for the top discharge of tablecloth production comprises a housing 10, a feed inlet 12 and a discharge outlet 13, the housing 10 has a processing chamber 11, and the processing chamber 11 is provided with parallel The first rotor 20 and the second rotor 30 are provided, the feed port 12 communicates with the upper opening of the processing chamber 11, the discharge port 13 communicates with the lower end opening of the processing chamber 11, and the material is fed from the The port 12 enters the processing chamber 11, and is squeezed and sheared by the first rotor 20 and the second rotor 30 in the processing chamber 11 to realize processing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com