A fully automatic capacitor taping machine and method thereof

A taping machine and fully automatic technology, applied in the field of fully automatic capacitor taping machine, can solve the problems of single detection method and wrong detection results, and achieve the effect of speeding up material collection, preventing capacitor installation from being reversed, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

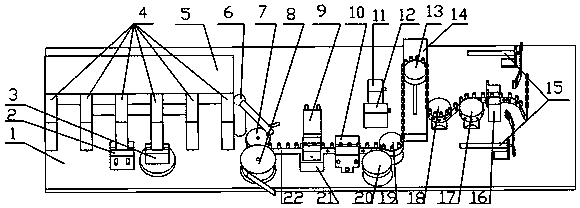

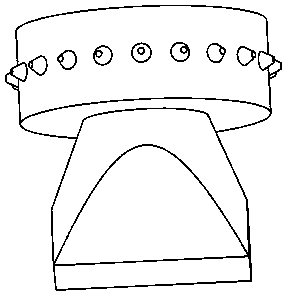

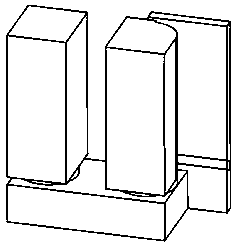

[0023] A fully automatic capacitance braiding machine, characterized in that it includes a frame 1, a first metal detection module 2, an indexing module 3, 6 sets of manipulators 4, a manipulator console 5, a first photoelectric detection module 6, and a first pulley 7. Second pulley 8, cylinder 9, second metal detection module 10, second photoelectric detection module 11, third metal detection module 12, sliding pulley 13, chute 14, two sets of push rods 15, braiding in half Module 16, counting pulley 17, third pulley 18, fourth pulley 19, fifth pulley 20, punching unit 21, capacitor braid 22 and receiving module; wherein the receiving module consists of two sets of lifting screw rods 24. Composed of a translation screw 25 and a slider 26; the first metal detection module 2 and the indexing module 3 are respectively fixed on the frame 1, the manipulator console 5 is fixed on the frame 1, and the 6 sets of manipulators 4 and the manipulator console 5 connected, the first photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com