Vacuum bag assembly for carbon fiber composite material and vacuum pumping method thereof

A composite material and vacuum bag technology is applied to the vacuum bag assembly for carbon fiber composite materials and the field of vacuuming, which can solve the problems of troublesome operation, increase processing cost, and can not solve the problems of broken bags, etc. Sealing effect, avoiding the effect of unsmooth air conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

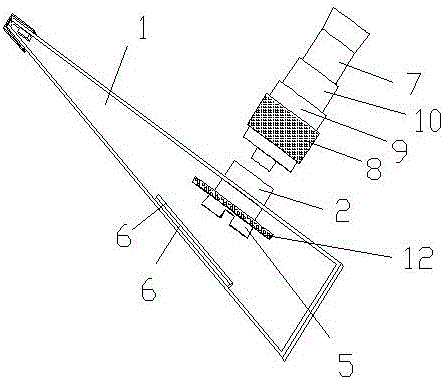

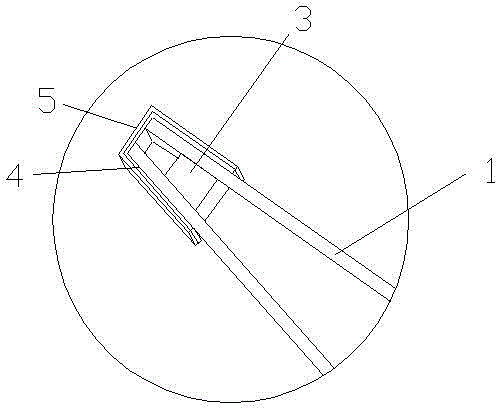

[0040] Such as Figure 1-2 As shown, this embodiment discloses a vacuum bag assembly for carbon fiber composite materials, including a vacuum bag 1 and a vacuum interface 2, the vacuum interface 2 is used to connect the vacuum bag 1 to a vacuum machine. It also includes a first sealing strip 3, a second sealing strip 4, an adhesive tape 5, and an air guiding cloth 6.

[0041] The vacuum bag 1 is a structure with three sides sealed and one side opened, and a vacuum interface 2 is arranged on its surface. One end of the vacuum interface 2 extends into the vacuum bag 1 , and the other end of the vacuum interface 2 extends out of the vacuum bag 1 . A suction nozzle 5 is provided at the end of one end of the vacuum port 2 protruding into the vacuum bag 1 .

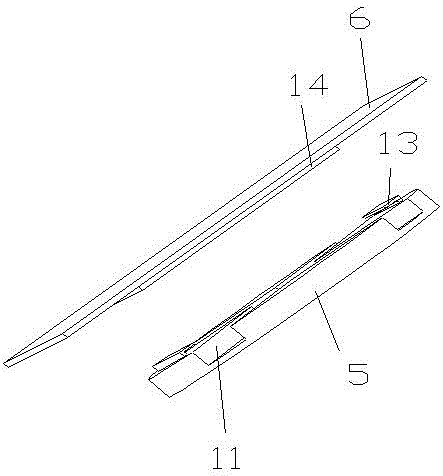

[0042] Such as Figure 4 As shown, an air guide groove 15 is opened on the end of the suction nozzle 5 , and the air guide groove 15 communicates with the vacuum interface 2 . The air guide cloth 6 is arranged in the vacuum...

Embodiment 2

[0058] Such as Figure 1-4 As shown, this embodiment discloses a method for vacuuming the above-mentioned carbon fiber composite material with a vacuum bag assembly, including the following steps:

[0059] (1) Put the material to be vacuumed into the vacuum bag 1 through the opening on the vacuum bag 1 .

[0060] (2) The first sealing strip 3 is placed between the two films of the opening, and the films are clamped to seal the opening to form a sealing edge.

[0061] (3) After sealing, trim off the excess, unsealed area of the two films.

[0062] (4) Wrap the sealing edge with one side of the second sealing strip 4 , and glue the other side of the second sealing strip 4 with adhesive tape 5 .

[0063] (5) Connect the vacuum tube body 7 to the vacuum interface 2, install the sealing gasket 8, the pressure ring 9, and the fastening nut 10 in sequence, and tighten the fastening nut 10.

[0064] (6) Connect the vacuum machine to the vacuum tube body 7, press down on the sucti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com