Adaptive sliding damping wheel for automobile

An adaptive and sliding technology, applied in the direction of wheels, highly elastic wheels, vehicle components, etc., can solve problems such as vehicle skids and traps, tires that cannot be driven due to flat tires, and damage to the shock absorption system, so as to save manpower, increase driving safety, Good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

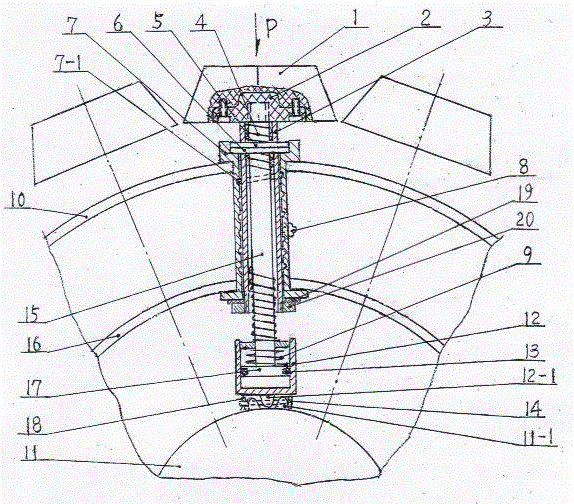

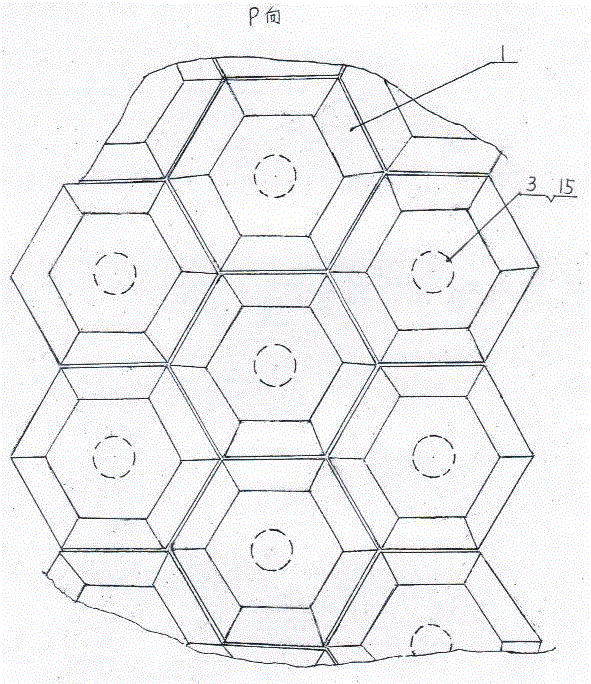

[0010] Example, reference sheet figure 1 , 2 , the self-adaptive sliding damping wheel for automobile is that several tire seat connecting bosses 11-1 are evenly arranged on the outer circumference of the tire seat 11, and the tire connecting seat bosses 11-1 correspond to two, according to the outer diameter of the whole tire And width, according to the bottom surface of each single regular hexagonal tire 1, the length of each side is 45mm, and each single regular hexagonal tire 1 is arranged at the required quantity of 1mm. A cylinder connecting boss 12-1 is inserted between every two tire seat connecting bosses 19-1, and the outer edge of the whole tire is an edge shape with angles. Use pin 14 to wear between tire connecting boss 11-1 and cylinder connecting boss 12-1, and the termination of pin 14 uses cotter pin 18 spacing. Fixedly connect the cylinder 12 above the cylinder connection boss 12-1, the piston 17 in the cylinder 12 is sealed with the inner wall of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com