Automatic feeding and counting machine

An automatic, sheet-feeding technology, applied in packaging and other directions, can solve problems such as difficult labor and lower production costs, and achieve low cost, reduced labor force, and good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

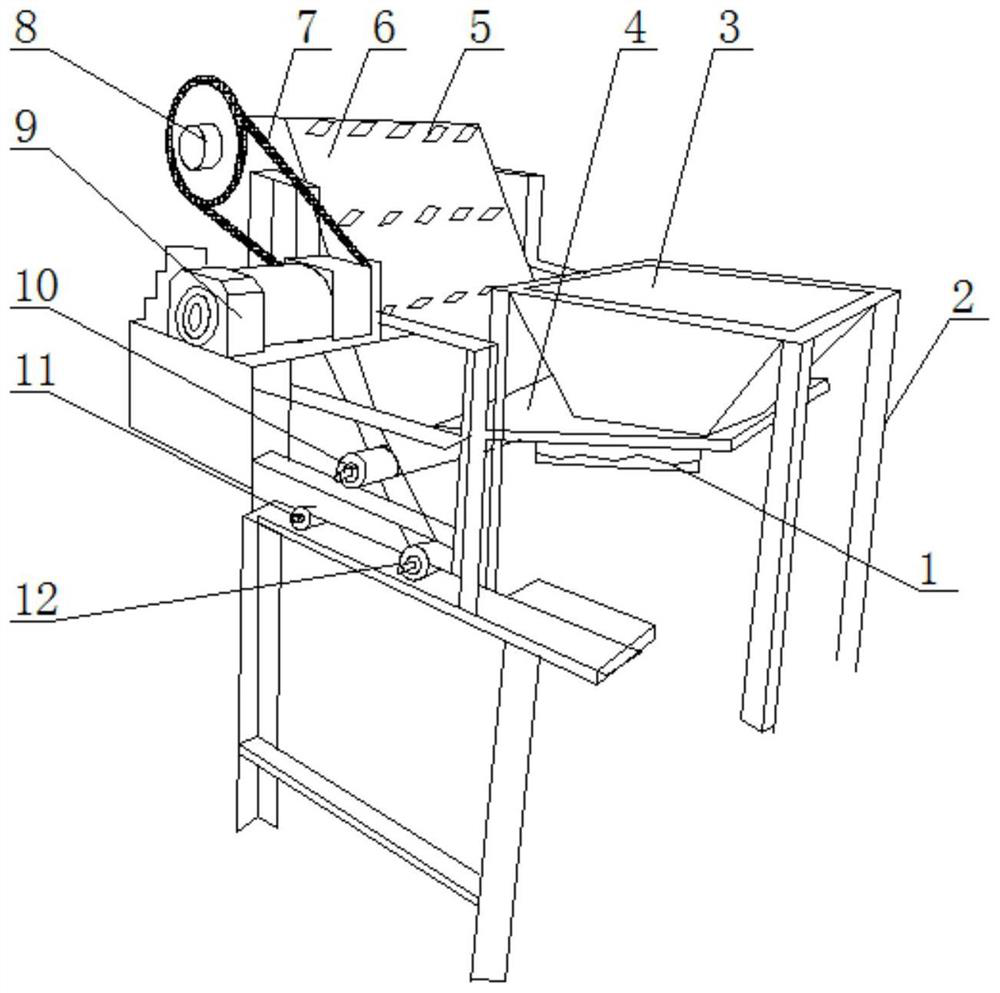

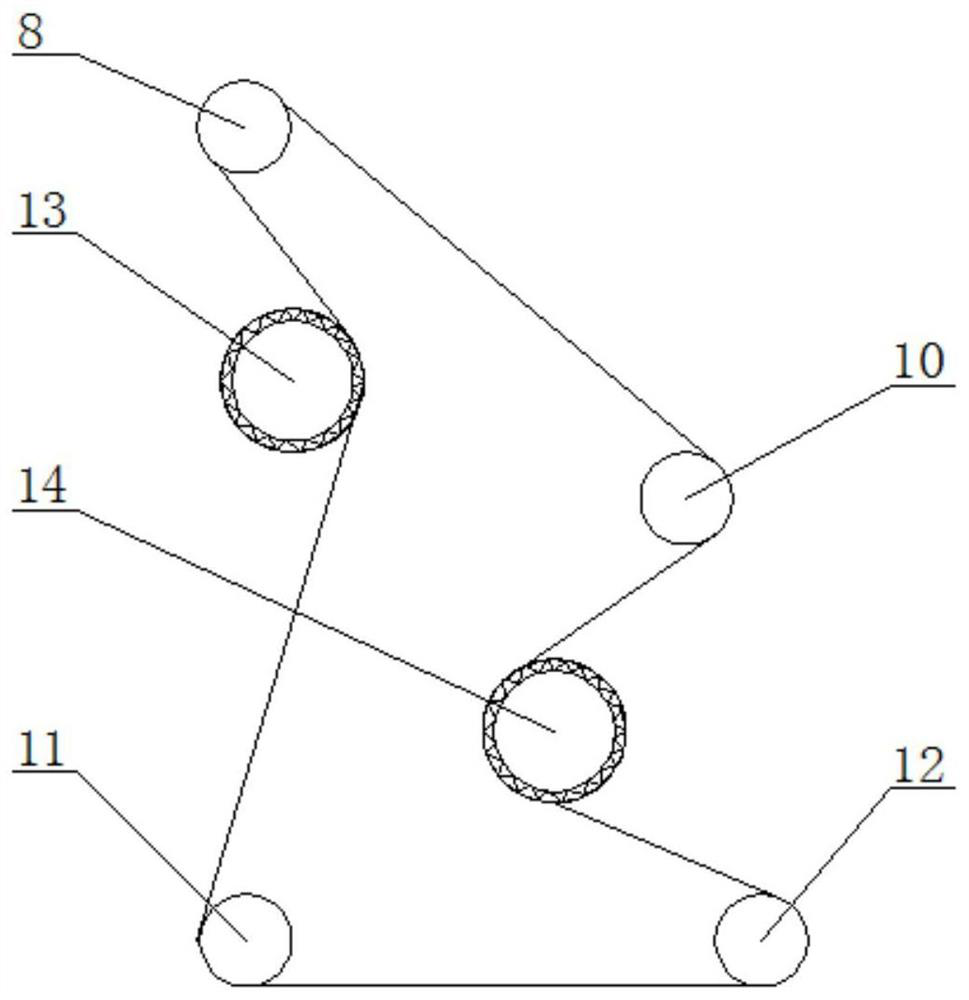

[0030] like figure 1 , figure 2 and image 3As shown in the figure, the automatic feeding machine includes a vibrating feeder, a support frame, a hopper, a blanking plate, a feeding tray, a lifting belt, a transmission device, a slow-feeding baffle, and a horizontal conveyor belt a. The support frames are respectively provided with There are a hopper, a lifting belt, and a transmission device. A blanking plate is arranged below the hopper. A vibrating feeder is installed at the bottom of the blanking plate. The free end of the blanking plate is set against the lower end of the lifting belt. Drive roller, adjusting roller, driven roller a, driven roller b, tensioning sprocket a, tensioning sprocket b, driven roller a and driven roller b are arranged at a distance from left to right along the same horizontal line Setting, the driving roller is set right above the driven roller a, an adjusting roller is arranged between the driving roller and the driven roller b, the adjusting...

Embodiment 2

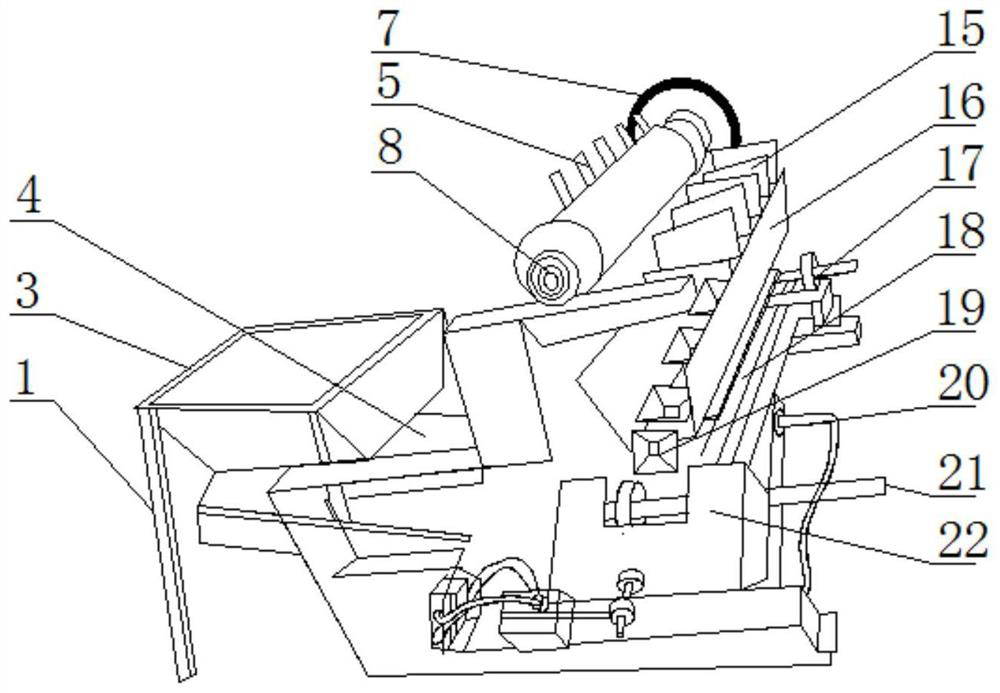

[0037] like Figure 1 to Figure 4 The automatic block counting machine includes an automatic feeding machine. The end of the horizontal conveyor belt a on the automatic feeding machine is provided with a distributor, and two horizontal conveyor belts b arranged in parallel are arranged below the distributor. The horizontal conveyor belt b A conveying tray is provided, and the ends of the conveying trays of the horizontal conveying belt a and the horizontal conveying belt b are respectively provided with a photoelectric switch I and a photoelectric switch II, the horizontal conveying belt b is driven by the motor b, and the horizontal conveying belt b is sleeved. On the horizontally arranged transfer roller III and transfer roller V, the ends of the transfer roller III and the transfer roller V are connected by a chain b, and the end of the transfer roller V is connected with the motor b; the end of the horizontal transfer belt b is provided with a material catcher The end of t...

Embodiment 3

[0043] like Figure 5 As shown in the figure, a packaging device is arranged below the feeder, and the packaging device includes a bracket, a bag holder, a support plate, a cylinder d, a suction cup, a rotating shaft, a cylinder e, a manipulator and a bagger, and a bag holder is arranged above the bracket. The bag holder is set as a hollow cylindrical body, the two symmetrical sides of the bag holder are respectively provided with a support plate a and a support plate b, the support plate b is provided with a cylinder d and a sliding guide rail, the piston rod of the cylinder d and the bag holder The middle part of the bracket is provided with a rotating shaft, the rotating shaft is connected with the middle part of the cylinder e, the rotating shaft is connected with the manipulator, the manipulator controls the rotating shaft to rotate 90°, thereby controlling the cylinder e to rotate 90°, the cylinder e and the supporting plate a are provided with suction cups at the relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com