A kind of production method of film hand-held rolling bag

A production method and continuous roll bag technology, which are applied in the field of film hand-held continuous roll bags, can solve the problems of no handle, not easy to separate, easy to separate at heat sealing, etc., and achieve the effect of saving materials, convenient use, and not easy to leak the bottom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

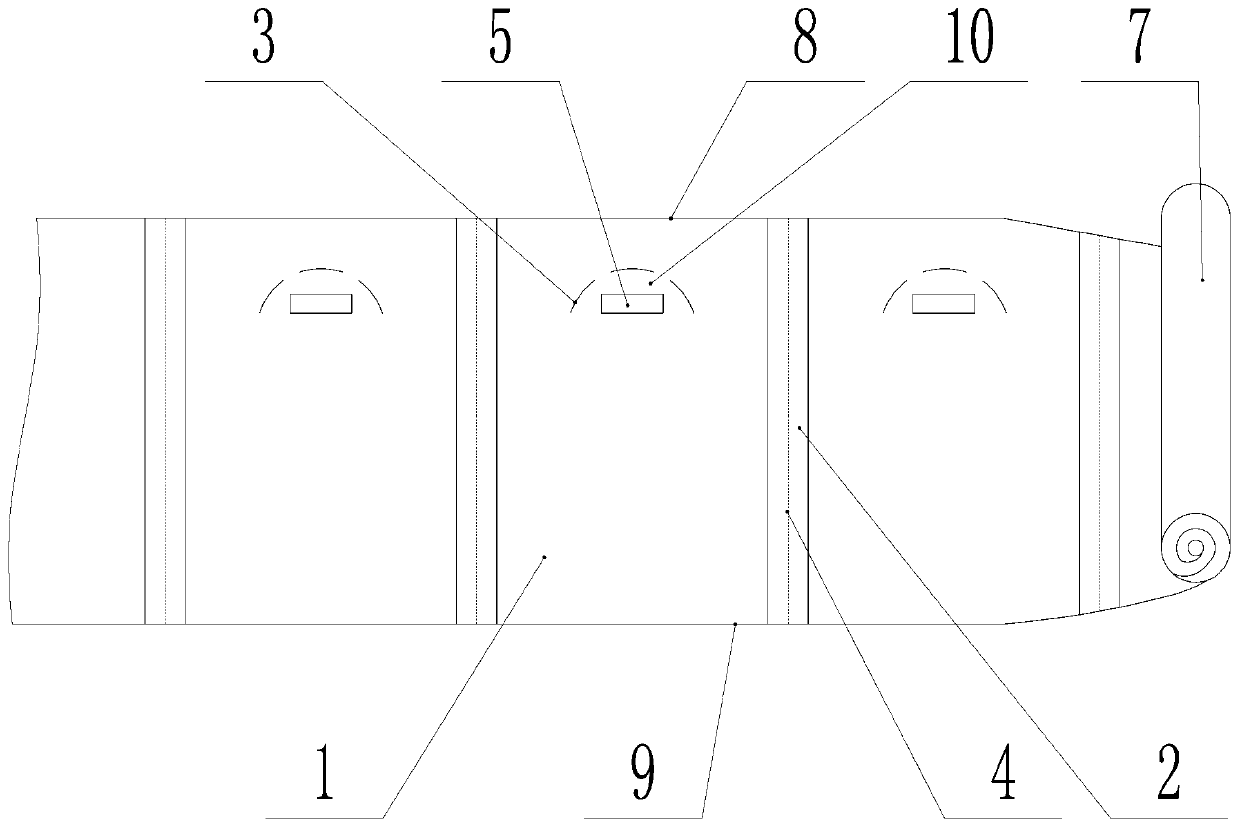

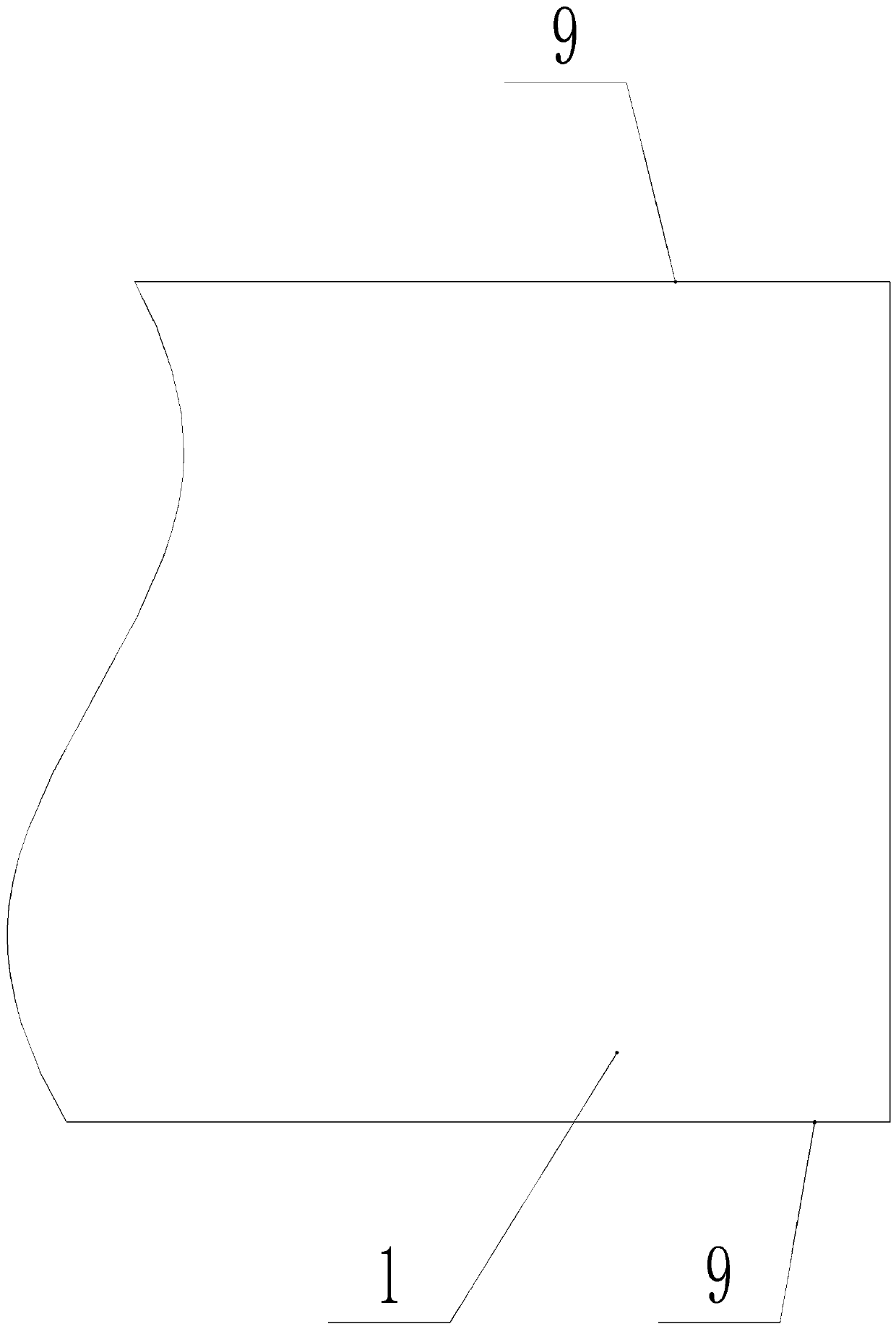

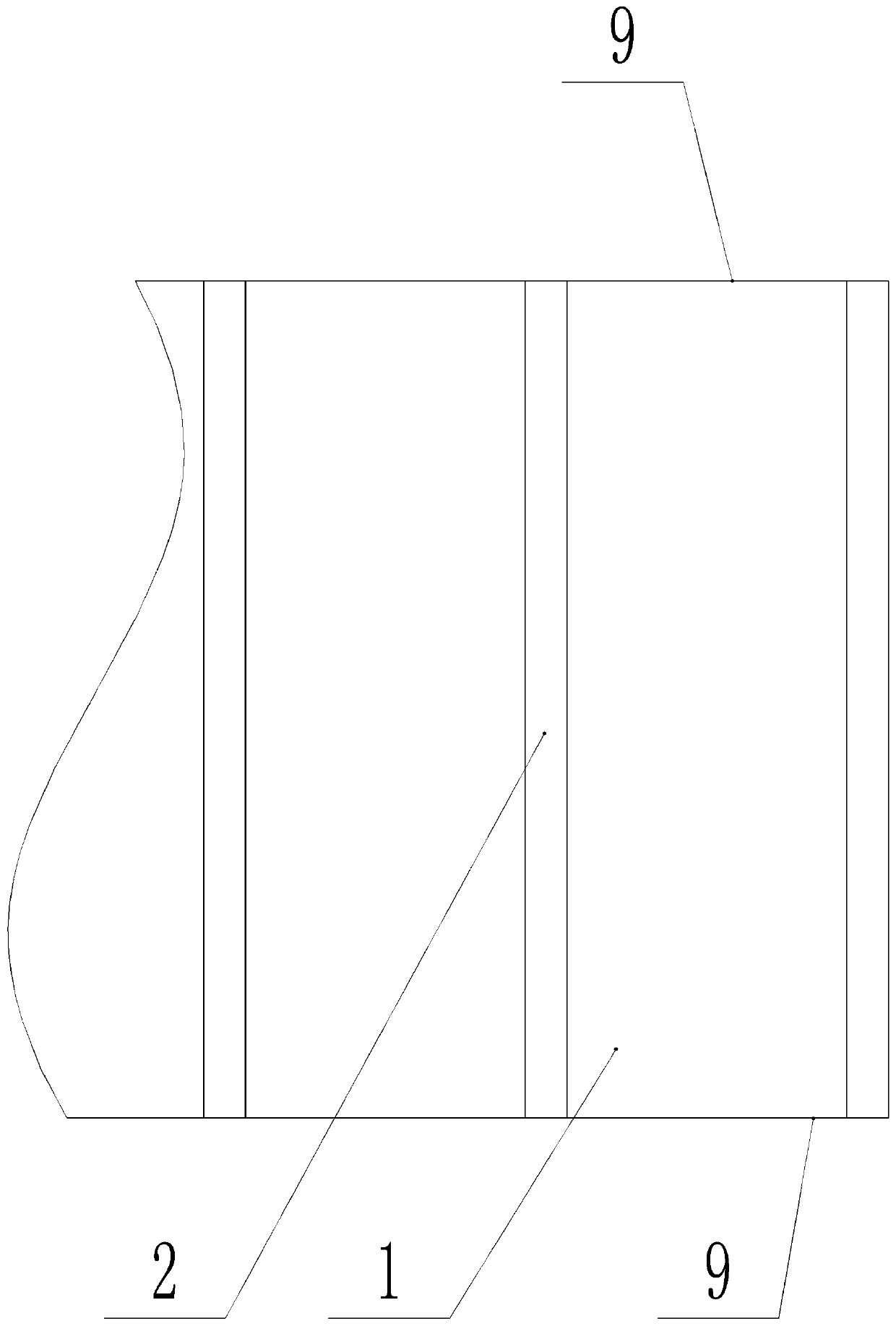

[0027] Such as figure 1 As shown, a film hand-held continuous roll bag includes a plurality of film bag bodies 1 that are sequentially connected and rolled into a reel, and a broken line 4 is provided between adjacent bag bodies 1, and two adjacent film bag bodies 1 is side connection, the bottom edge 9 of the bag body 1 is the folded edge, the bottom edge 9 is the bottom of the film bag, the side edges on both sides of the bag body 1 are heat-sealing edges 2, the top of the bag body 1 is the pocket 8, and the bag body 1 The arc-shaped broken line 3 provided at the lower part of the mouth 8 is the handle.

[0028] Described arc broken mark line 3 is apart from pocket mouth 4-6cm, and this example is 5cm.

[0029] The two sides of the bag body below the arc-shaped fracture line 3 are hinged sheets 10 , and the outside of one of the folded leafs 10 is a self-adhesive sheet 5 .

[0030] The arc-shaped fracture line 3 is divided into three parts, the distance between two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com