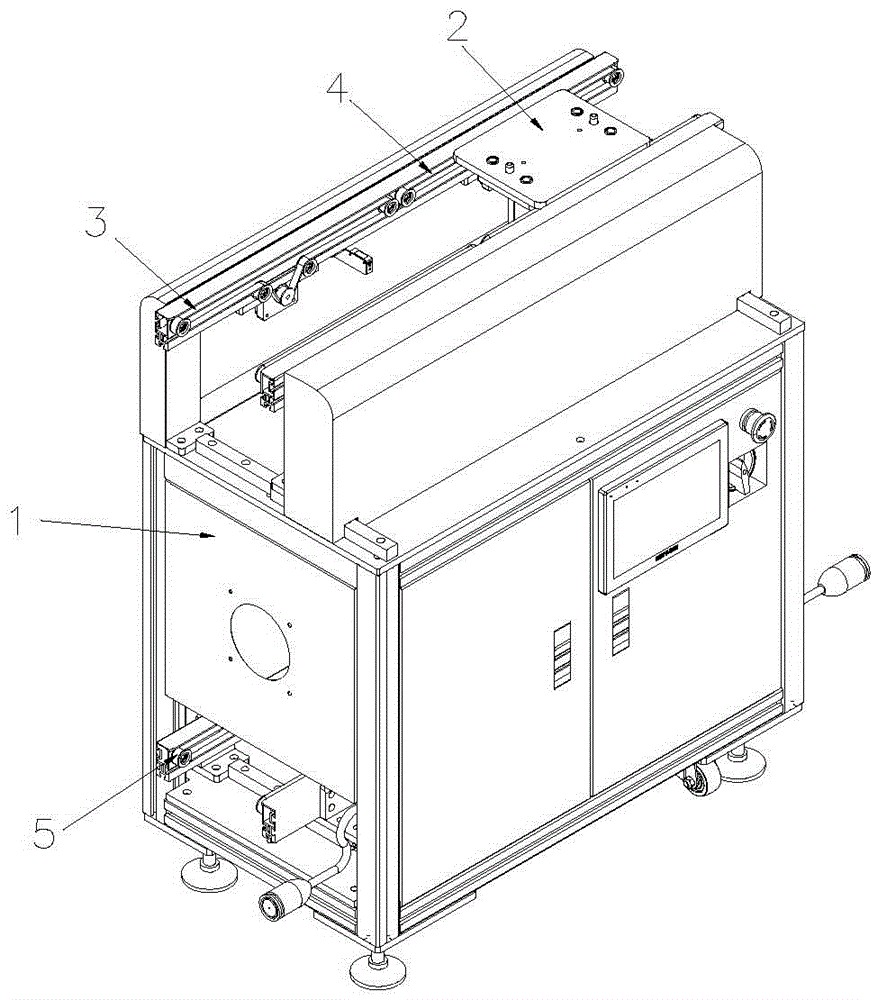

Conveying device and conveying line body thereof

A technology of conveying device and conveying mechanism, which is applied in the direction of conveyor control device, conveyor, mechanical conveyor, etc., can solve the problems of real-time control of product flow or stop by conveyor belt, increase production cost, and produce defective products, etc. To achieve the effect of reducing the use of labor, reducing collisions, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

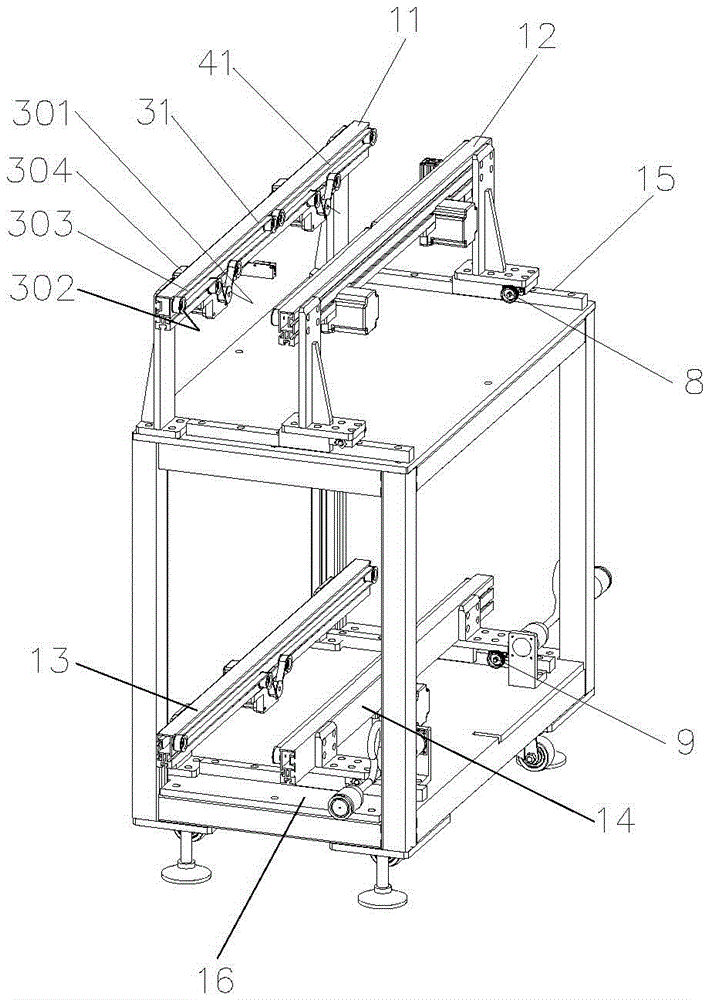

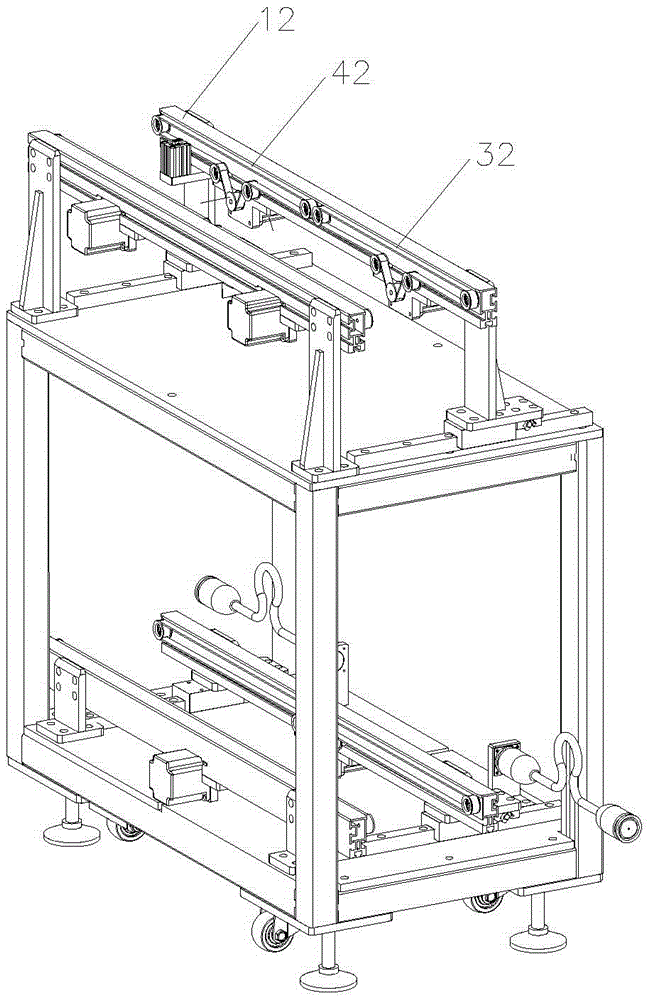

[0038] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

[0039] A conveying device of the present invention includes a frame 1, and at least one conveying device for conveying loading boards. The conveying device includes a front conveying mechanism 3 and a rear conveying mechanism 4 docked with the front conveying mechanism 3. The preceding section conveying mechanism 3 includes a first conveying mechanism 31 and a second conveying mechanism 32 arranged on the support 1, and the first conveying mechanism 31 and the second conveying mechanism 32 all include a first driving pulley 301, a first slave Driving pulley 302, the first motor 303 for driving the first driving pulley 301 to rotate and the first synchronous belt 304 connecting the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com