Double-load weighing system for scissor-fork-type lifting working platform

The technology of a working platform and weighing system, which is applied in the direction of lifting frame, lifting device, lifting equipment safety device, etc., can solve the problems of reducing work efficiency, being unable to carry loads, and not being able to give full play to the advantages of scissor-type lifting work platforms, etc. Achieve the effect of improving work efficiency and exerting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

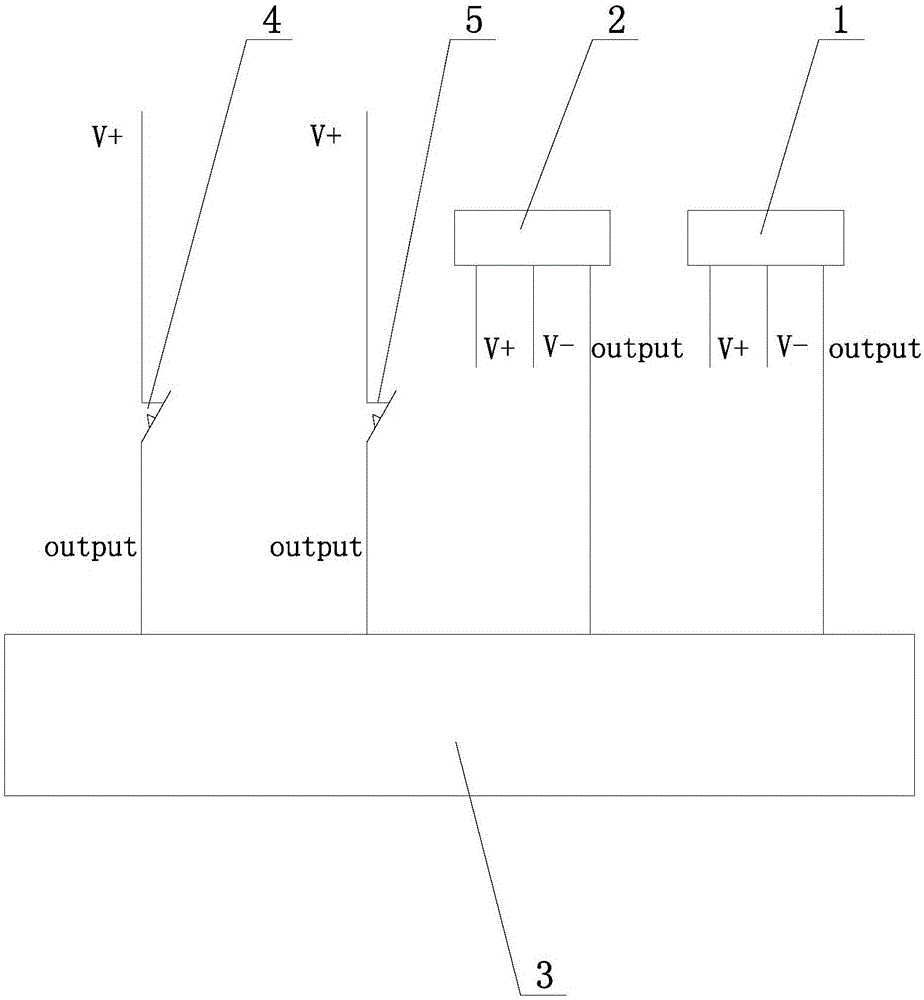

[0019] Such as figure 1 As shown in the figure, a double-load weighing system for scissor lift work platforms includes an angle sensor 1 for recording the lifting height of the work platform and a pressure sensor 2 for recording the lifting pressure of the oil cylinder. The angle sensor 1 and the pressure sensor 2 are respectively passed through wires It is connected with the electrical control unit 3, and the electrical control unit 3 is respectively connected with the low limit switch 4 and the maximum limit switch 5 through wires. By designing the angle sensor 1, the lifting height of the working platform can be detected in real time, and the lifting height can be transformed into The electrical signal is transmitted to the electrical control unit 3; through the design of the pressure sensor 2, the lifting pressure of the oil cylinder under the rated power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com