PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) composition with good paint spraying property and preparation method of PC/ABS composition

A technology of composition and ABS resin, which is applied in the field of spraying polymers and polymer materials, can solve the problems of decreased compatibility, general chemical resistance, discounted bonding force between materials and paint layers, etc., so as to improve the etching resistance 、Excellent spraying performance, avoiding the effect of biting the bottom and spraying cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

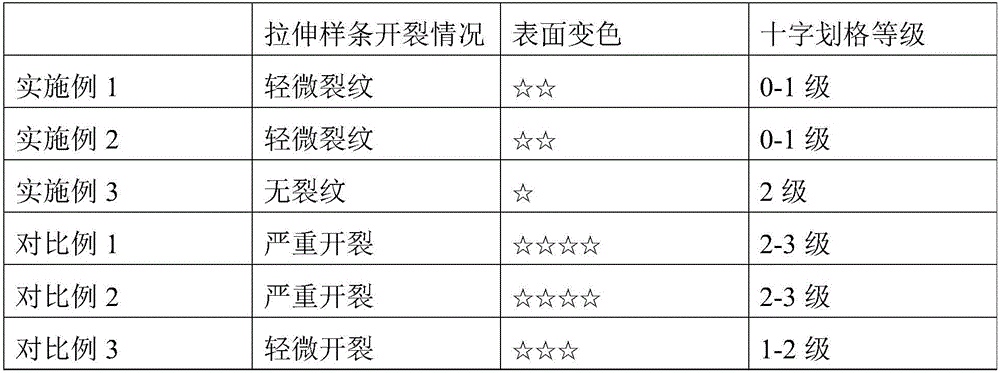

Examples

Embodiment 1

[0035] The present embodiment provides a kind of PC / ABS composition and preparation method thereof with good sprayability, and the method comprises the following steps:

[0036] (1) Weigh each component by weight: PC is PC-1220:60, ABS8434:40, talcum powder 3, antioxidant 10100.1, antioxidant 168 0.1, lubricant PETS 0.3.

[0037] (2) After mixing all the raw materials evenly, feed them from the feeding port of the extruder, melt and extrude at 220-260°C, the screw extruder speed is 500rpm, the pressure is 2MPa, after melt extrusion, granulation is get the product.

Embodiment 2

[0039] The present embodiment provides a kind of PC / ABS composition and preparation method thereof with good sprayability, and the method comprises the following steps:

[0040] (1) Weigh each component by weight: PC is L1250Y: 80, ABS8434: 20, talcum powder 3, antioxidant 10100.1, antioxidant 168 0.1, lubricant PETS 0.3.

[0041] (2) After mixing all the raw materials evenly, feed them from the feeding port of the extruder, melt and extrude at 220-260°C, the screw extruder speed is 500rpm, the pressure is 2MPa, after melt extrusion, granulation is get the product.

Embodiment 3

[0043] The present embodiment provides a kind of PC / ABS composition and preparation method thereof with good sprayability, and the method comprises the following steps:

[0044] (1) Weigh each component by weight: PC is PC-1220: 70, ABS8434: 30, talcum powder: 5, antioxidant 10100.1, antioxidant 168 0.1, lubricant PETS 0.3.

[0045] (2) After mixing all the raw materials evenly, feed them from the feeding port of the extruder, melt and extrude at 220-260°C, the screw extruder speed is 500rpm, the pressure is 2MPa, after melt extrusion, granulation is obtained product.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap