A dual-channel centrifugal injector structure for a variable-thrust solid-liquid rocket engine

A solid-liquid rocket and engine technology, which is applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as difficult to ensure injection pressure drop and engine performance, and achieve compact structure, convenient processing, and good atomization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the drawings.

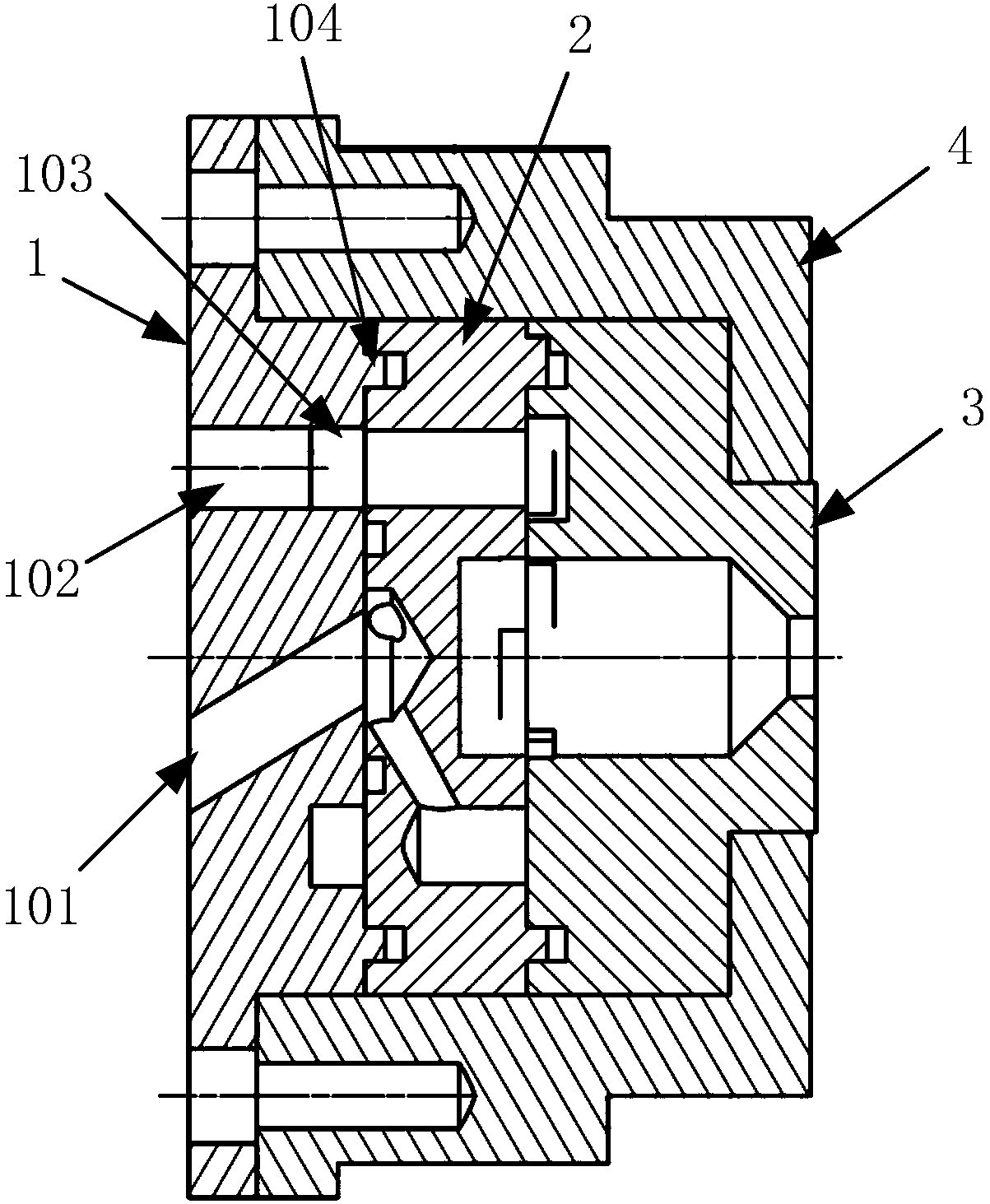

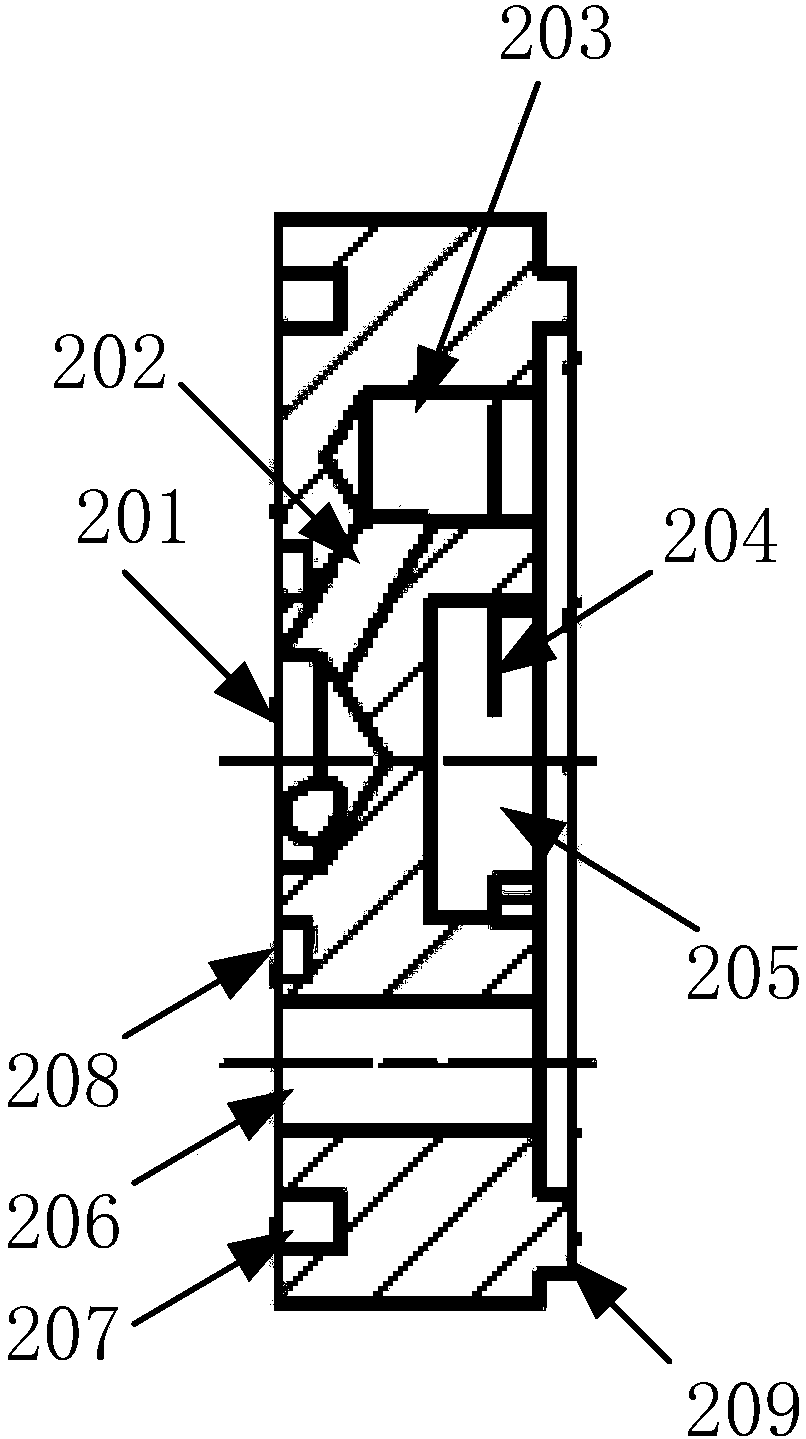

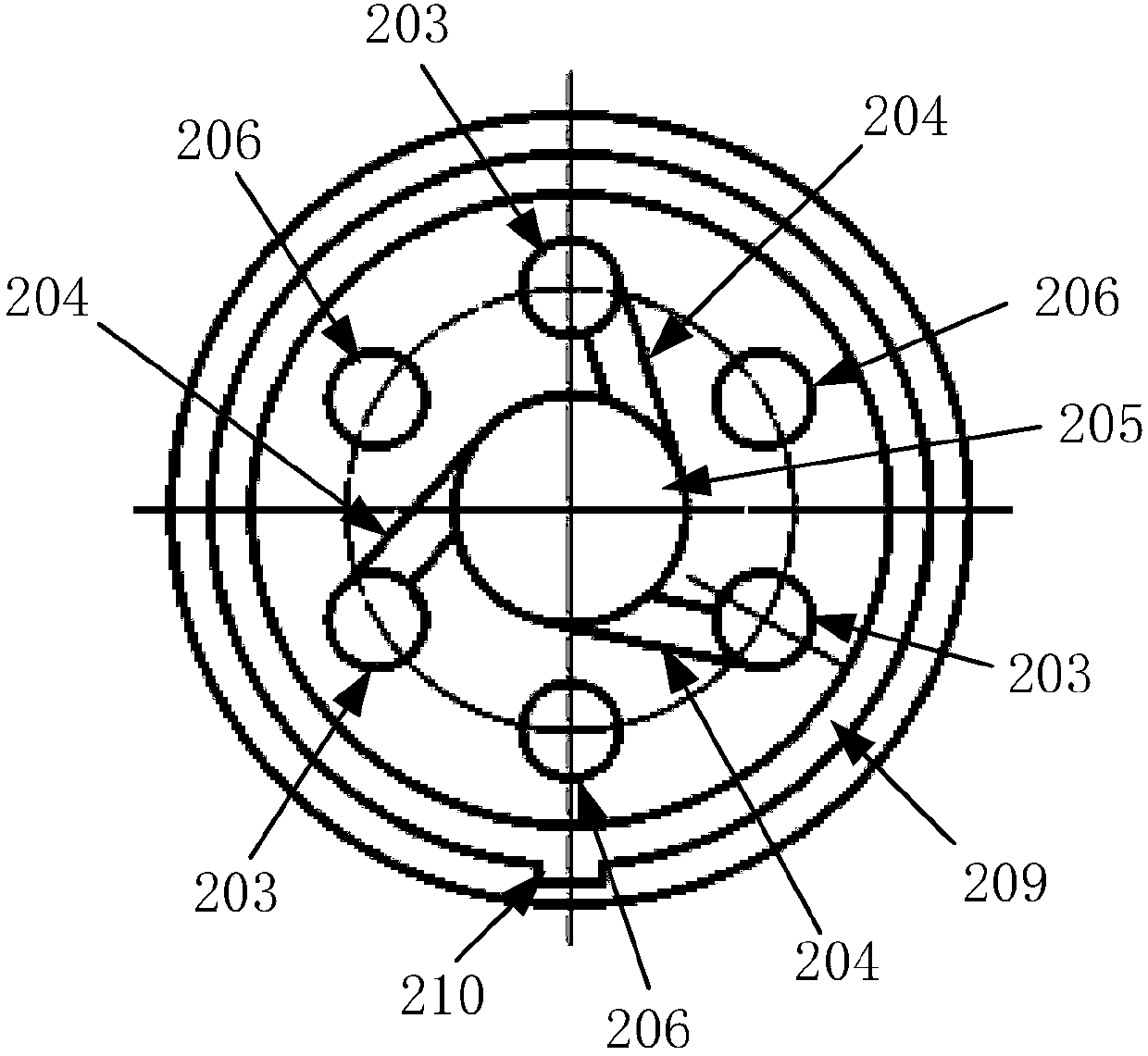

[0033] The two-way centrifugal injector structure of the variable thrust solid-liquid rocket engine of the present invention includes a spray cover 1, a liquid distributor 2, a nozzle 3 and a shell 4, such as figure 1 Shown.

[0034] The nozzle 3, the dispenser 2 and the spray cover 1 are cylindrical and are coaxially arranged in the cylindrical casing 4 from front to back, and the outer wall and the inner wall of the casing 4 are circumferentially matched. Among them, the front end of the nozzle 3 and the front end of the casing 4 are coordinated and positioned with a shoulder in the circumferential direction; the spray cover 1 is positioned in conjunction with the shoulder of the rear end of the casing 4 in the circumferential direction, and is fixed to the casing 4 by screws, and at the same time, the spray cover 1 The nozzle 3 and the dispenser 2 are compressed and fixed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com