Ultrasonic non-destructive measurement method for fillet weld leg size and internal defects

A technology of solder foot size and internal defects, applied in measuring devices, using ultrasonic/sonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problem of difficulty in obtaining solder foot size, and the waveform read by the data gate is not accurate enough , the difficulty of accurately evaluating the strength of actual components, etc., to achieve the effect of fast ultrasonic scanning and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides an ultrasonic non-destructive measurement method for the size of the weld leg of an aluminum alloy fillet weld:

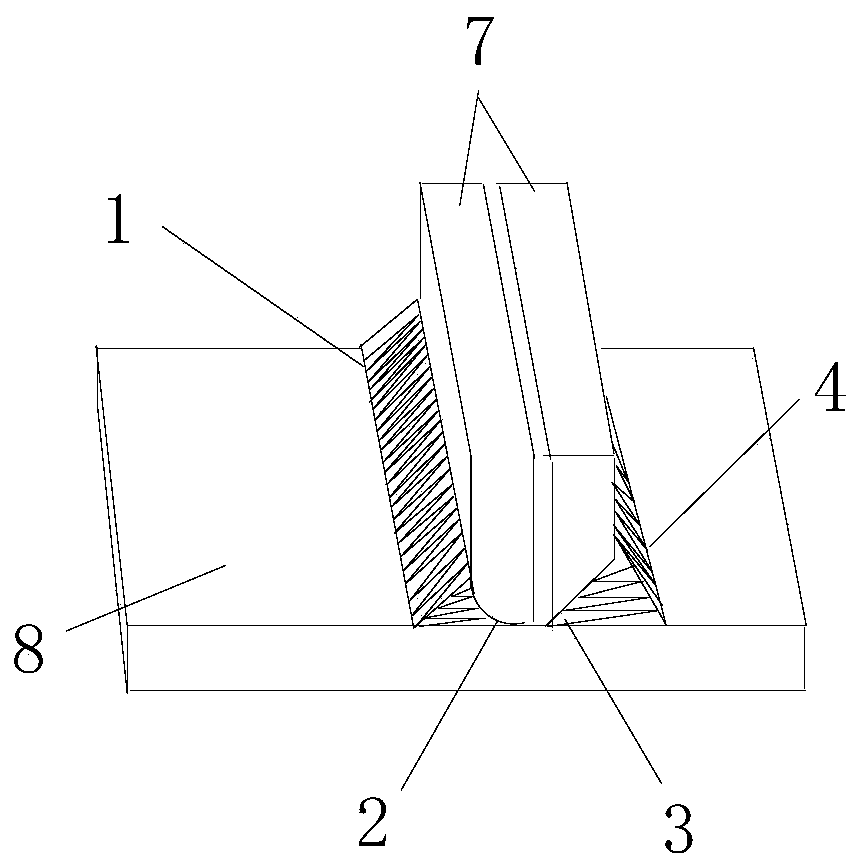

[0044] It includes a first welded plate, and welds a second welded plate with a welded area at a certain angle with the first welded plate. The welded area includes a fillet weld or an unfused hole. The weld term of the fillet weld structure is based on GB / T3375-94 Definitions of Welding Terms.

[0045]Preferably, the first welding plate is vertically welded on the second welding plate, and the first welding plate and the second welding plate form a T shape after welding.

[0046] The first welding plate includes grooves for welding, or no grooves for welding;

[0047] Specific measurements include:

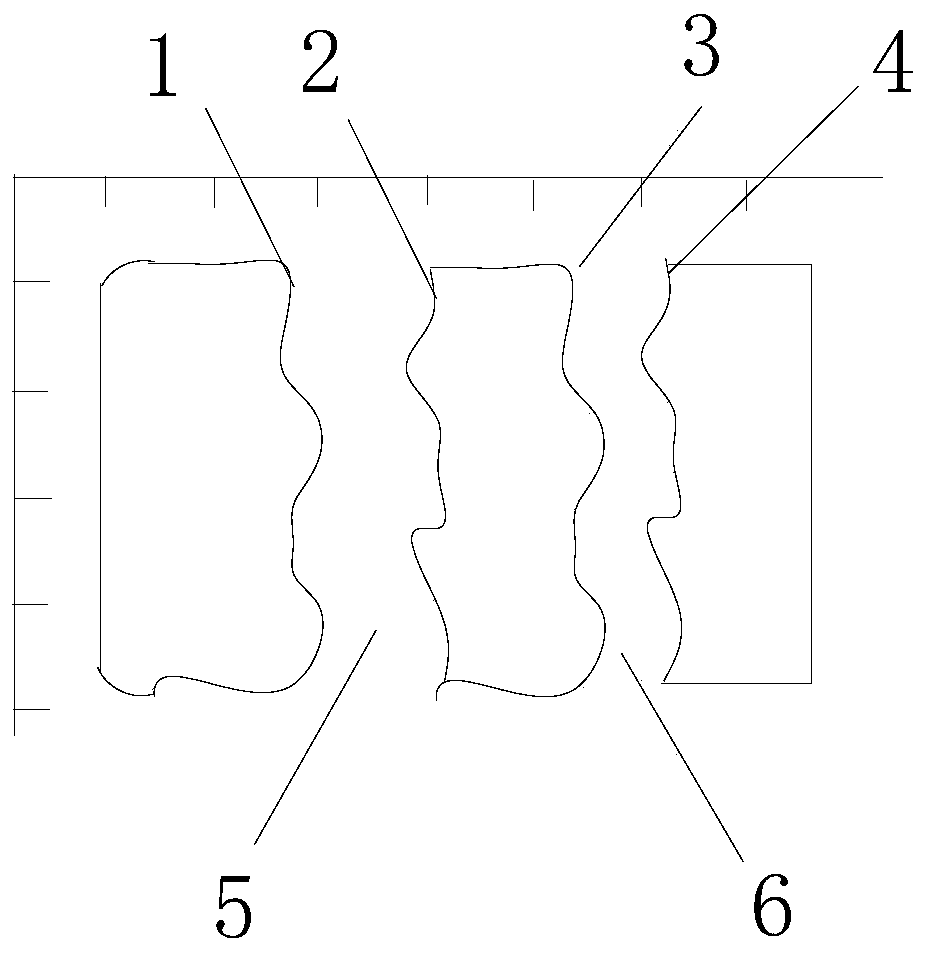

[0048] S1. Scanning the second welding plate to obtain the reflected echo of the target section;

[0049] S2. Perform visual scanning according to the reflected echo, and obtain a plan view of the target section represented by the e...

Embodiment 2

[0086] This embodiment provides an imaging method, including a phase imaging method. Ultrasonic reflected echoes contain amplitude and phase information, but commonly used ultrasonic equipment only uses echo amplitude information, and the actual echo signal phase also reflects the medium condition inside the object, even more sensitive. In this system, the phase difference is converted into gray value or color value for imaging.

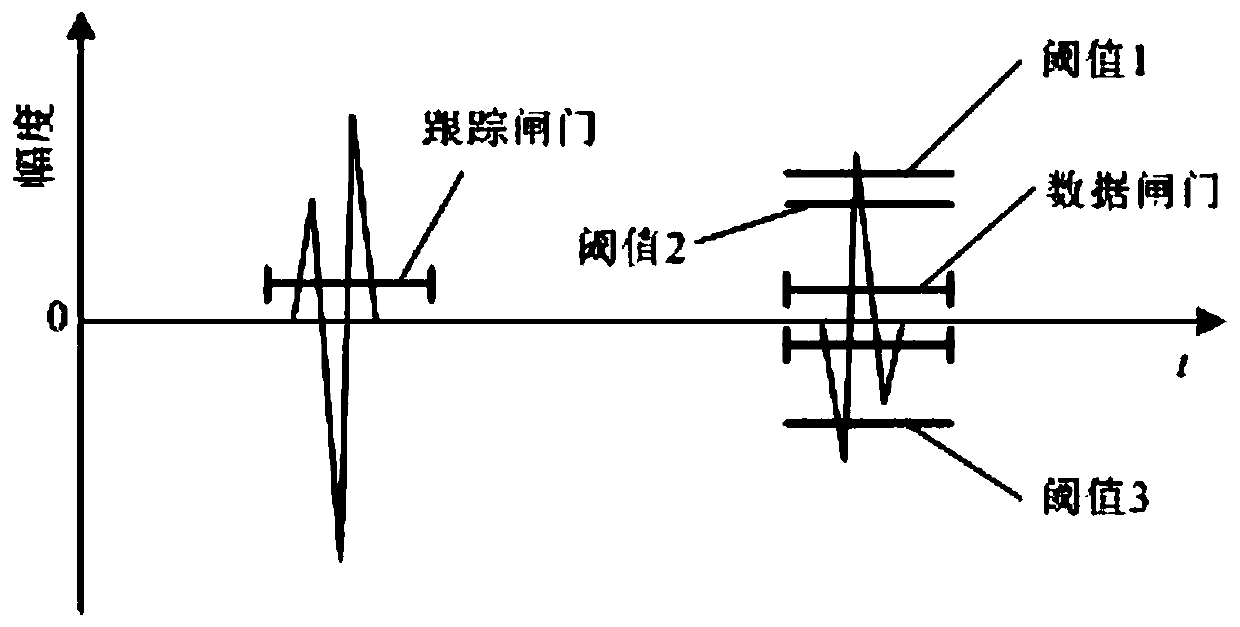

[0087] Further, the gray-scale plan includes obtaining the gray-scale plan by using phase imaging, and the phase imaging determines whether the phase of the waveform read by the second gate is reversed by setting the threshold value when the waveform data is read by the second gate .

[0088] The threshold is set to 2-4;

[0089] Preferably, the threshold includes 3, threshold 1, threshold 2 and threshold 3, wherein threshold 1 and threshold 2 are positive values, and threshold 3 is negative;

[0090] Optionally, the system can also use frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com