Method used for garbage dynamic weighing of sanitation truck

A technology of dynamic weighing and collection and transportation vehicles, which is applied in the direction of garbage storage, weighing, and special scales, etc., can solve the problems of inability to monitor and dispatch the reprinted volume in real time, unable to monitor and dispatch the reprinted volume, and reduce work efficiency, etc., to achieve Improve the efficiency of garbage weighing, meet the environmental sanitation weighing, and achieve the effect of accurate weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

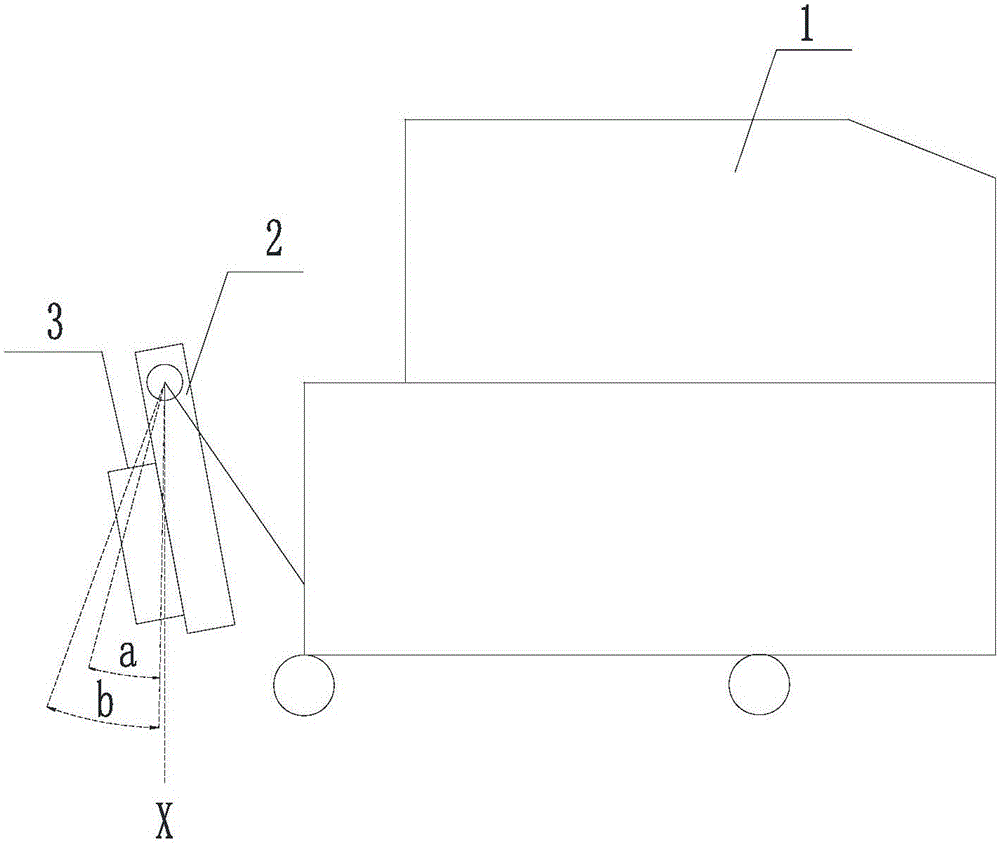

[0016] Attached below figure 1 and figure 2 The present invention is further described.

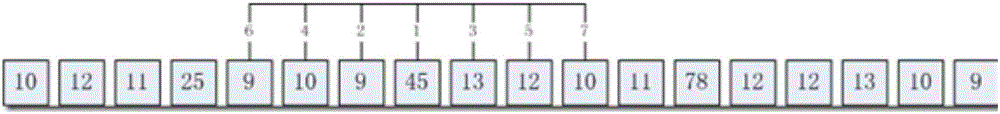

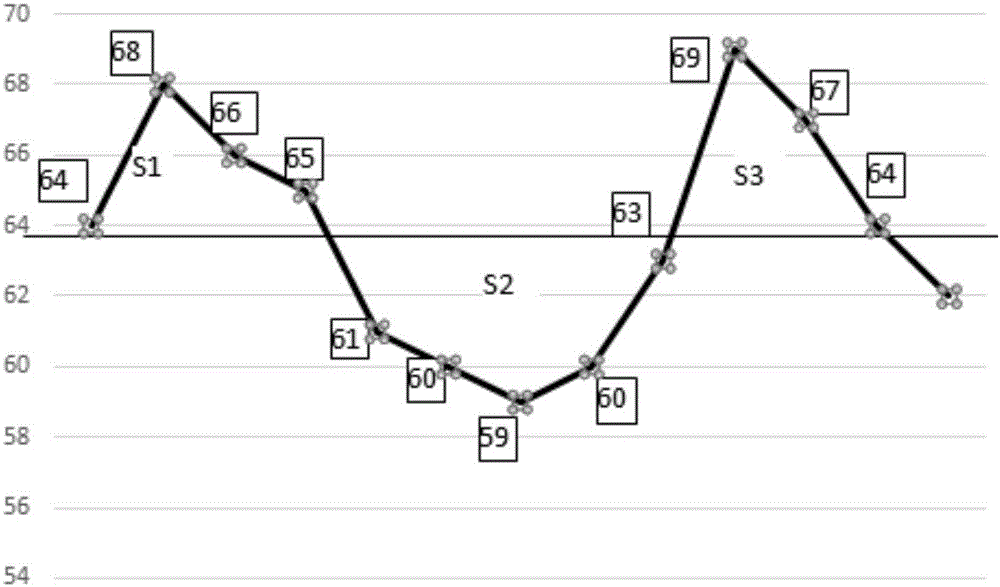

[0017] like figure 1 As shown, a method for dynamic weighing of garbage in the sanitation collection and transportation vehicle, the garbage in the garbage can is poured on the sanitation collection and transportation vehicle, and the sequence includes the following steps: (1) Hanging the bucket, the bracket on the sanitation vehicle 1 is directed towards the garbage The barrel 3 moves until the trash can 3 hangs on the support 2, specifically, the support 2 is slightly offset from the vertical axis by a negative angle, generally -1~-2°, moves in a direction parallel to the vertical axis and rises to touch the edge of the trash can 3 ; (2) carrying the bucket, the support 2 drives the garbage can 3 to rise, and the garbage can 3 leaves the ground; (3) rotating movement, the garbage can 3 is turned towards the sanitation collection and transportation vehicle 1 with the rotation angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com