A split type ladle needle jumper

A split-type, ladle technology, applied in the field of optical fiber jumpers, can solve the problems of easy damage to the end face of optical fiber pins, inconvenient manual operation, sticking to dust or dirt, etc., so as to achieve convenient and direct manual operation and save materials. , the effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

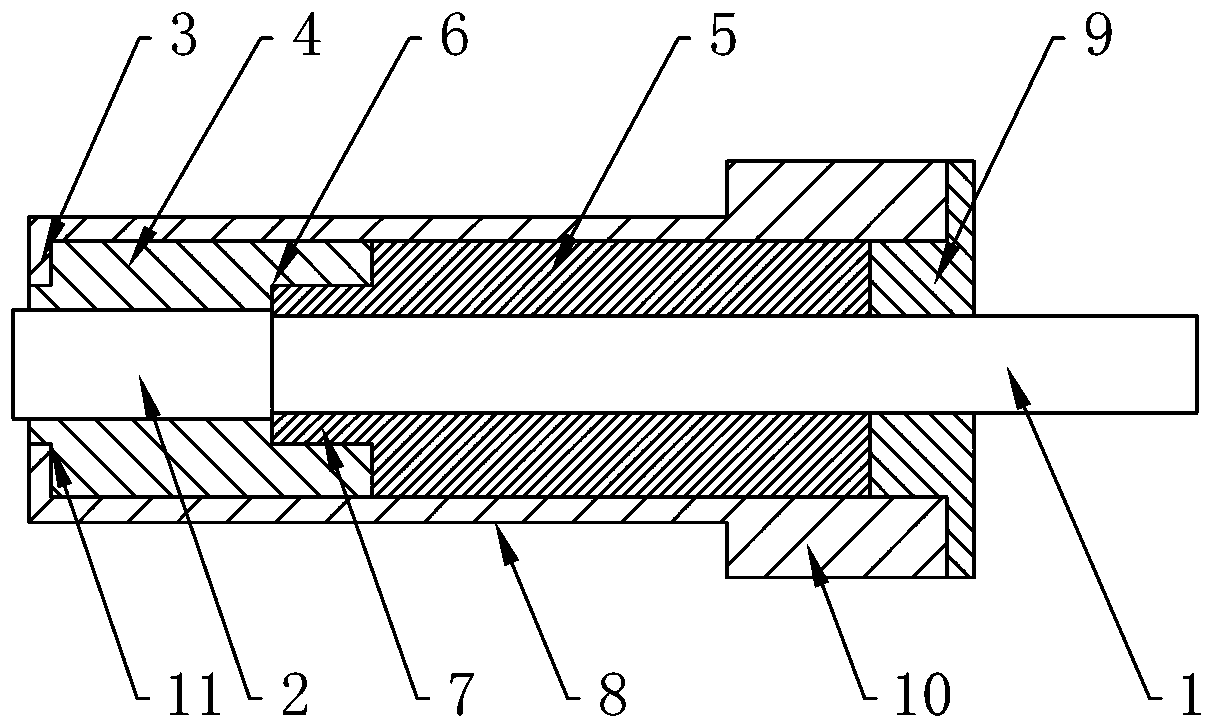

[0015] Such as figure 1 As shown, a split-type ladle pin jumper according to the present invention includes an optical fiber cable 1, an optical fiber ferrule 2 and a connector. The connector includes a first connecting part 4 and a second connecting part 5. The first connecting part 4 Sleeved on the fiber optic ferrule 2 and the first connection part 4 is fixedly connected to the fiber optic ferrule 2, the second connection part 5 is sleeved on the fiber optic cable 1 and the second connection part 5 is fixedly connected to the fiber optic cable, the first connection part The inner circumference of 4 is concavely provided with an annular groove 6, and one end of the second connecting portion 5 close to the first connecting portion 4 is provided with a protruding ring 7 matching the annular groove 6, and the outer periphery of the connector is provided with a sheath 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com