Systematic design method of embedded type module cross test

A technology of embedded systems and design methods, applied in software testing/debugging, etc., can solve problems such as limiting maximum power, increasing the number of use cases, and poor cross-testing design, to ensure completeness and reduce workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

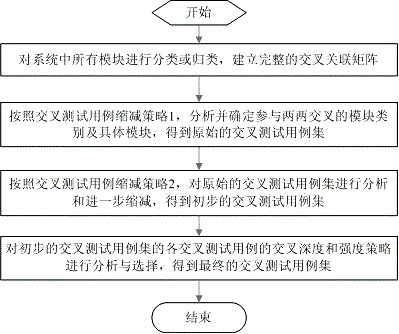

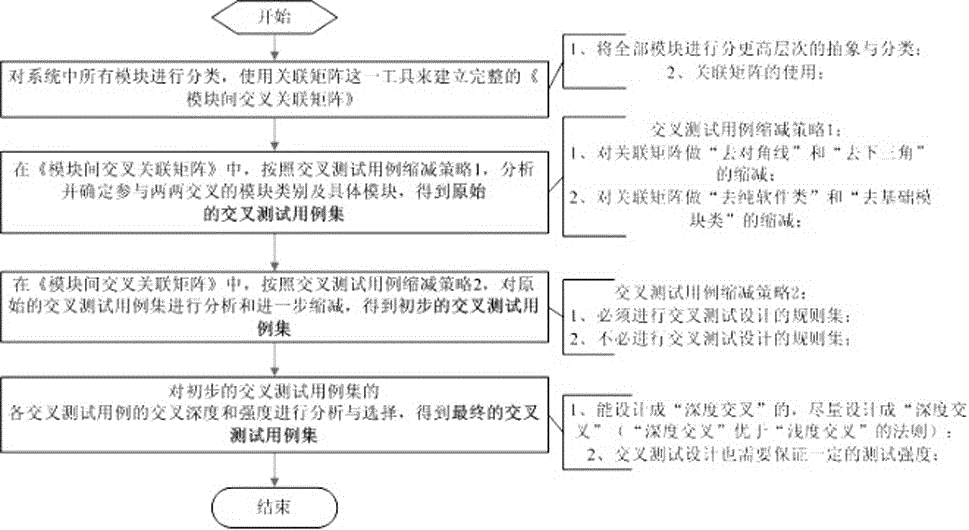

[0030] like figure 1 As shown, a systematic design method of an embedded module cross-test of the present invention comprises the following steps,

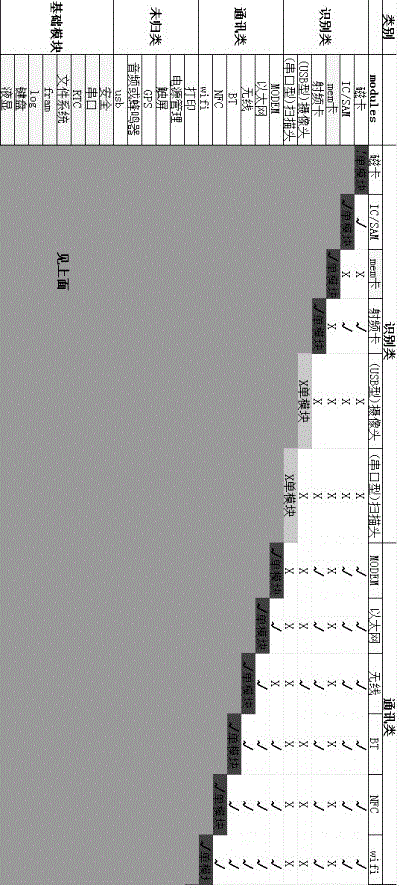

[0031] S1: Classify or classify all modules in the embedded system, and establish a complete inter-module cross-correlation matrix;

[0032] S2: According to the reduction strategy of cross test cases in the first step, analyze and determine the module categories and specific modules participating in pairwise cross, and obtain the original cross test case set;

[0033] S3: According to the second step cross-test case reduction strategy, analyze and further reduce the original cross-test case set to obtain a preliminary cross-test case set;

[0034] S4: Analyze and select the intersection depth and intensity of each intersection test case in the preliminary intersection test case set, and ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com