Ship full life circle product data management system

A technology of product data management and full life cycle, applied in data processing applications, instruments, office automation, etc., can solve problems such as inability to realize full life cycle management, and achieve difficult tracking control, high information integration capabilities, and improved management horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings.

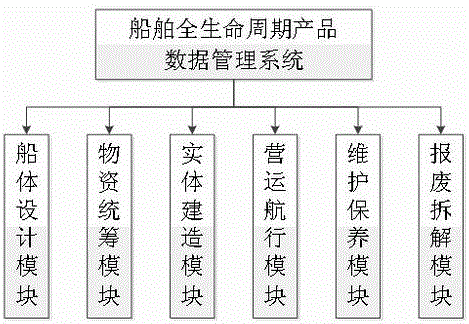

[0023] figure 1 It is stated that the product data management system of the whole life cycle of the ship includes seven modules, namely the ship design module, the material coordination module, the physical construction module, the operation navigation module, the maintenance module and the scrapping and dismantling module.

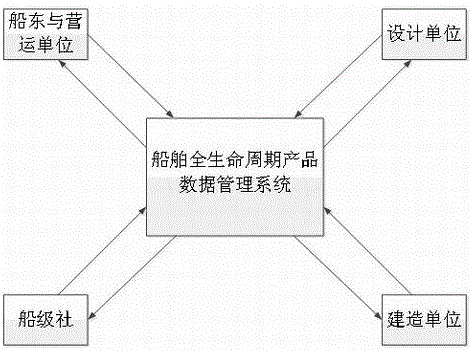

[0024] figure 2 It states that the product data management system for the whole life cycle of a ship is jointly used by shipowners, operating units, design units, classification societies and construction units to enhance the speed of information exchange between them.

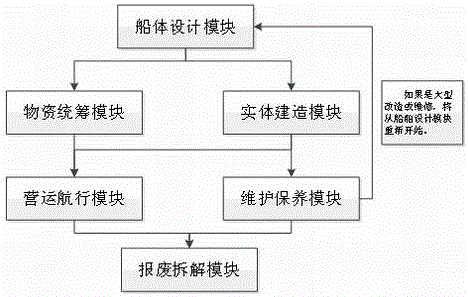

[0025] image 3 It describes the use stage of the product data management system in the whole life cycle of the ship. The ship design module is used first. When the design drawings are approved by the classification society and approved by the shipowner and the operating organiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com