Self-locking power-off time delay protector

A technology of power-off delay and protector, applied in the direction of thermal switch components, etc., can solve problems such as disconnection, hidden circuit safety hazards, and environmental temperature reduction of thermal bimetals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

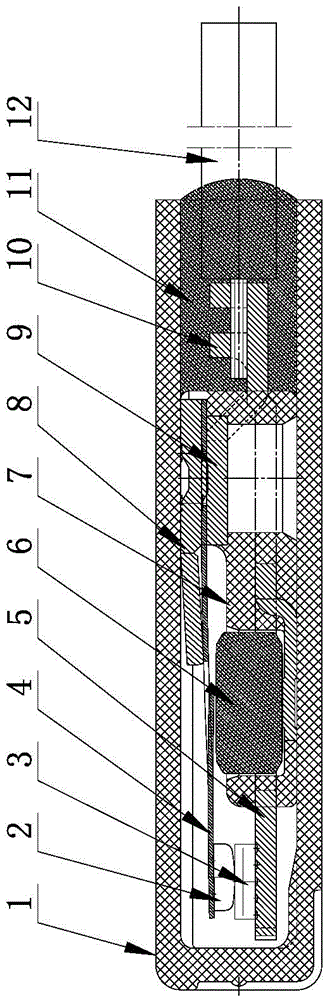

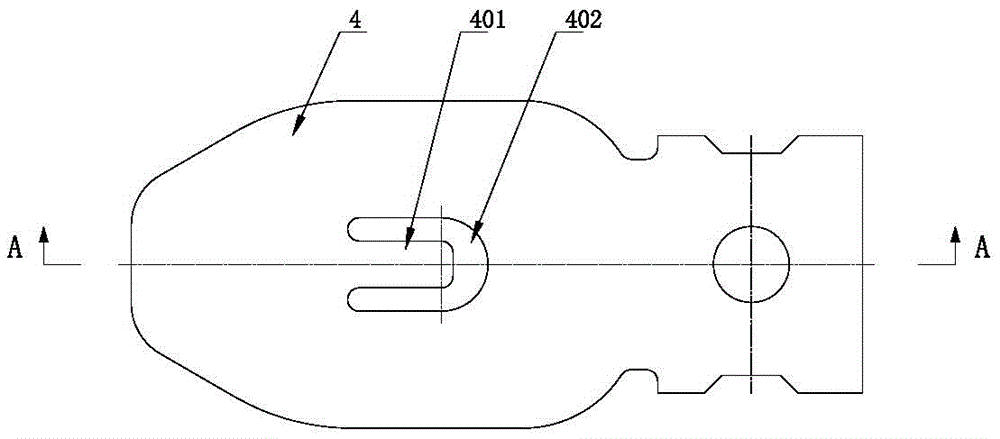

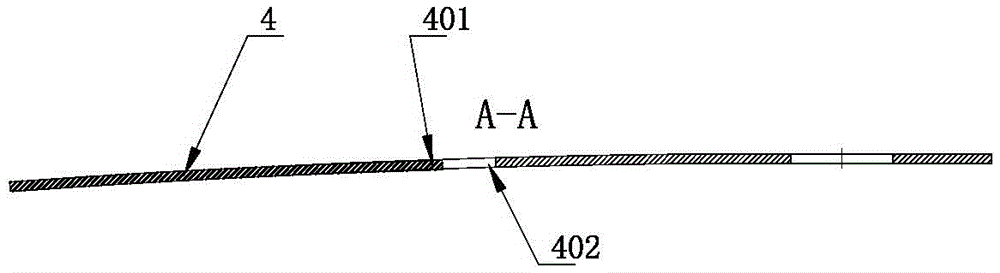

[0023] like Figure 1-8 The self-locking power-off delay protector shown includes a housing 1 with one end open, and an overcurrent and overheating protection component is arranged inside the housing 1, and the end of the overcurrent and overheating protection component is connected with a Two wires 12, the opening of the housing 1 is sealed by the sealant 11, and forms a sealed cavity, the overcurrent and overheating protection components include the static contact piece 5, the moving contact piece 9, and the temperature calibration piece 8 installed in the insulating support seat 7 And the temperature calibration sheet 8 of the thermal bimetal sheet 4 is pressed tightly in the insulating support seat 7, and the end of the temperature calibration sheet 8 is in contact with the top surface of the middle part of the thermal bimetal sheet 4, and the bottom of the temperature calibration sheet 8 Processing has the welding boss 802 that compresses and fixes the thermal bimetal 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com