Manual rotating type oven body

A baking oven and rotating technology, which is applied in the direction of baking equipment, household utensils, applications, etc., can solve the problems that affect the grilling effect, the ingredients cannot be rotated, and the pins cannot be rotated, etc., so as to improve the grilling effect and improve the uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

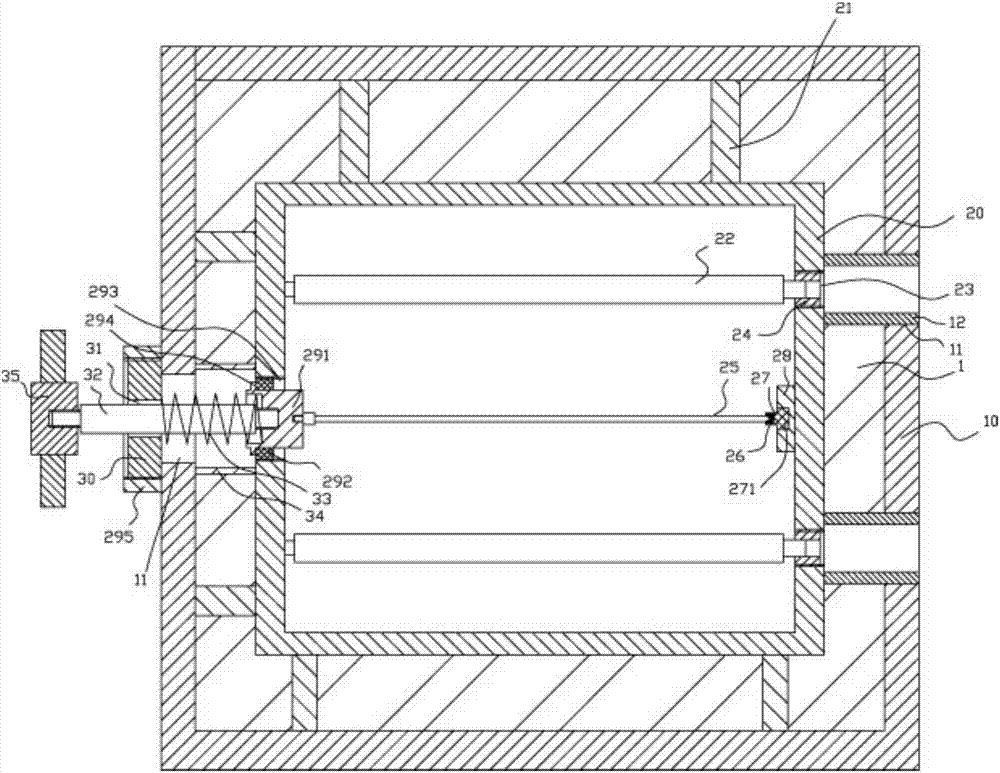

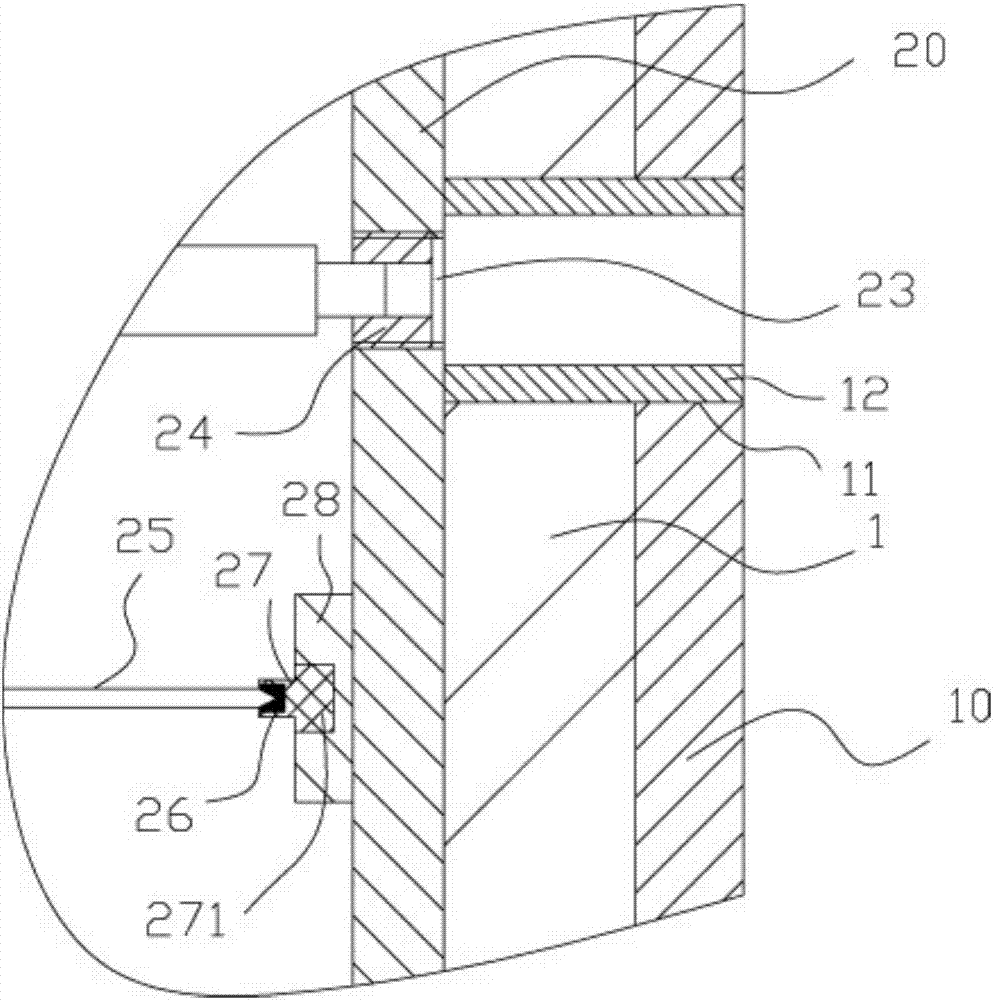

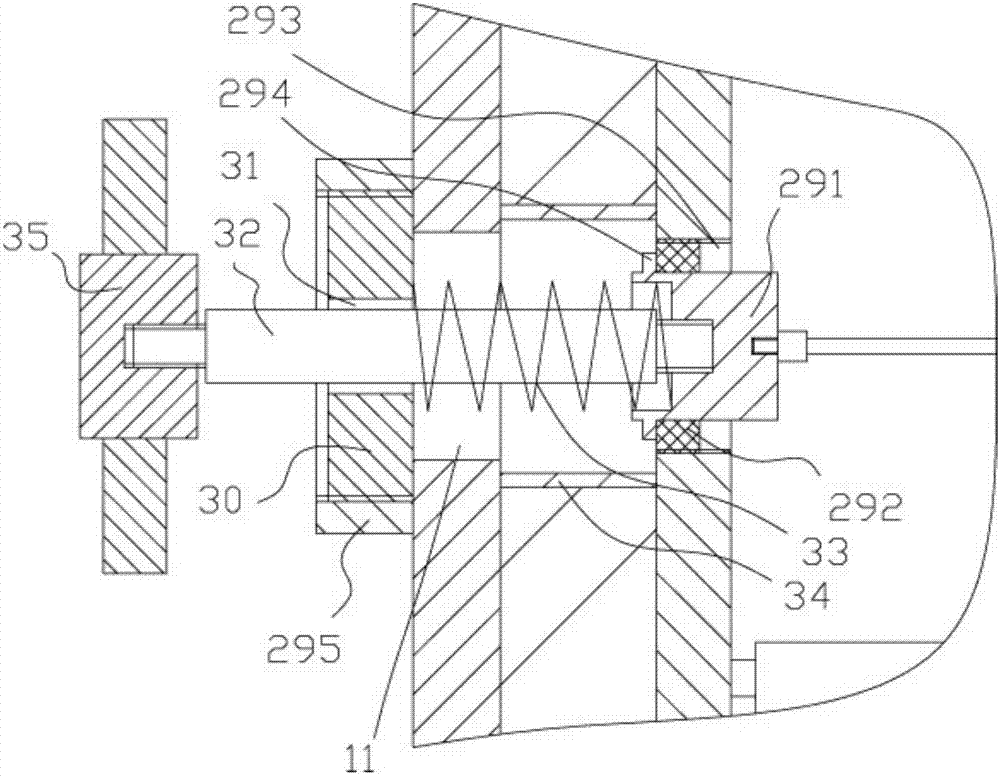

[0020] Example: see Figure 1 to Figure 3 As shown in the figure, a manual rotating oven box body includes a box body 10, an inner box body 20 is arranged inside the box body 10, and a plurality of connecting plates 21 are fixed on the outer side wall of the inner box body 20, and the connecting plates The other end of 21 is fixed on the inner side wall of the box body 10, and the upper and lower parts of the inner box body 20 are provided with heating rods 22, and the inner box body 20 between the heating rods 22 of the upper part and the lower part is provided with a central pin 25. The right end of the central pin 25 is inserted into the side wall socket at the left end of the right connecting block 26 and is adsorbed to the right connecting block 26, and the right connecting block 26 is inserted into the sleeve and clamped on the left end of the right self-lubricating block 27 In the main concave hole, the rotating part 271 on the right end of the right connecting block 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com