A new method for preparing high-purity asthma medicine pranlukast

An asthma drug and a new method technology, applied in the field of organic drug synthesis, can solve the problems of cumbersome operation, high cost, and low content of pranlukast crude product, and achieve the effect of simple process and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

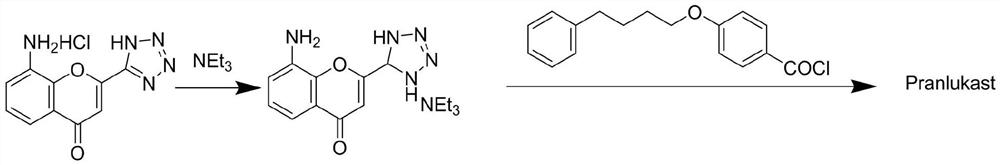

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 80 g of 8-amino-4-oxo-2-tetrazol-5-yl-4H-1 benzopyran hydrochloride in 500 ml of dichloromethane, add 65 g of triethylamine dropwise, and reflux for reaction after dropping After 2h, the dichloromethane was recovered, the residue was stirred at 0℃ for 30min, and then filtered with suction to obtain the intermediate 8-amino-4-oxo-2-oxazol-5-yl-4H-1-benzopyran Triethylamine salt 93g.

[0019] 67g of 8-amino-4-oxo-2-oxazol-5-yl-4H-1-benzopyran monotriethylamine salt and 60g of p-phenylbutoxybenzoyl chloride were put into a 700ml dichloromethane After stirring and refluxing for 6 hours in a 1000ml reaction flask, dichloromethane was recovered, 1200ml of 5% alkaline water was added to the remainder, stirred, and a little activated carbon was added for decolorization, freezing and crystallization to obtain Pranlukast sodium salt, and then the obtained Pranlukast Ster sodium salt was put into 500ml ethanol, 500ml water was added, and the pH was adjusted to 6.8-7.2 with ...

Embodiment 2

[0021] 80g of 8-amino-4-oxo-2-tetrazol-5-yl-4H-1 benzopyran hydrochloride was dissolved in 500ml of dichloromethane, 50g of pyridine was added dropwise, and the reaction was refluxed for 2h after dropping. The dichloromethane was recovered, and the residue was stirred at 0°C for 30 min, and filtered with suction to obtain the intermediate 8-amino-4-oxo-2-oxazol-5-yl-4H-1-benzopyran monopyridine salt 86g.

[0022] 62g of 8-amino-4-oxo-2-oxazol-5-yl-4H-1-benzopyran monopyridine salt and 60g of p-phenylbutoxybenzoyl chloride were put into 1000ml reaction containing 700ml of dichloromethane After stirring and refluxing for 6 hours, the dichloromethane was recovered, and 1200ml of 5% alkaline water was added to the remainder, stirred, and a little activated carbon was added for decolorization, frozen and crystallized to obtain the sodium salt of Pranlukast. Sodium salt was put into 500ml ethanol, 500ml water was added, pH was adjusted to 6.8-7.2 with hydrochloric acid while stirring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com