Method for catalyzing and synthesizing S-acetyl-L-glutathione from mixed solvent

A technology of glutathione and synthetic methods, which is applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the difficulty of selective acylation of sulfhydryl groups, acetyl-CoA is not easy to obtain, and is not suitable for large-scale industrial production, etc. problem, to achieve the effect of high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

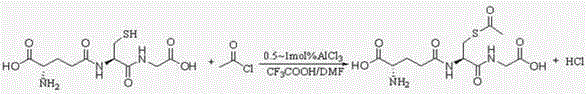

Image

Examples

Embodiment 1

[0022] Add glutathione 50g (0.16mol), 106mg AlCl 3 , 200mL of trifluoroacetic acid and 200mL of DMF, stir well, then raise the temperature to 40°C, add 13.8g (0.176mol) of acetyl chloride dropwise while stirring, take 10min, keep warm for 15min, TLC detects that there is no raw material point, drop 1.0g Methanol was incubated at 40°C for 15 minutes, and the solvent was recovered under reduced pressure after the reaction. Add 900mL of acetone / water (2:1) mixed solution to it and stir to dissolve. After dissolving, add triethylamine dropwise to adjust the pH to about 3. Add 300mL of acetone dropwise under slow stirring, let stand for crystallization for 1 hour after dropping, slowly cool down to 0°C, crystallize for 3 hours, filter with suction, rinse the filter cake with about 50-100mL of solvent and dry it at 70°C, that is S-acetyl-L-glutathione product 50.1g was obtained, the product yield was 89.5%, and the purity of the product detected by HPLC was greater than 99.3%.

Embodiment 2

[0024] Add 50g (0.16mol) of glutathione, 200mL of trifluoroacetic acid and 200mL of DMF into a 1 L three-necked flask equipped with a reflux condenser, a thermometer, and a mechanical stirrer, stir evenly, raise the temperature to 40°C, and add acetyl chloride dropwise while stirring 13.8g (0.176mol), it took 10min, and the temperature was kept for 15 minutes after dripping. TLC detected that there was no raw material point, and 1.0 g of methanol was added dropwise, and the reaction was kept for 15 minutes at 40°C. After the reaction, the solvent was recovered under reduced pressure. Add 900mL of acetone / water (2:1) mixed solution to it and stir to dissolve. After dissolution, triethylamine was added dropwise to adjust the pH to about 3. Add 300mL of acetone dropwise under slow stirring, let stand for crystallization for 1 hour after dropping, slowly cool down to 0°C, crystallize for 3 hours, filter with suction, rinse the filter cake with about 50-100mL of solvent and dry it ...

Embodiment 3

[0026] Add 50 g (0.16 mol) of glutathione, ZnCl 2 108mg, add 400mL trifluoroacetic acid, stir evenly, raise the temperature to 35°C, add 17.6 g (0.224mol) of acetyl chloride dropwise while stirring, take 10 minutes, keep warm for 20 minutes after dropping, TLC detects that there is no raw material point, drop 5.9g Ethanol was incubated at 35°C for 15 minutes, and the solvent was recovered under reduced pressure after the reaction. Add 900mL of acetone / water (2:1) mixed solution to it and stir to dissolve. After dissolving, trimethylamine was added to adjust the pH to about 3. Add 400mL of acetone dropwise under slow stirring, let stand for crystallization for 1 hour after dropping, slowly cool down to 0°C, crystallize for 3 hours, filter with suction, rinse the filter cake with about 50-100mL of solvent and dry it at 70°C, that is Obtain S-acetyl-L-glutathione product 48g, product yield 85.7%, HPLC detection product purity is greater than 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com