Faucet capable of improving usage safety of heating heat exchanger

A technology for heat exchangers and faucets, applied in the field of faucets, can solve problems such as hazards, heat loss in heating systems, and increased valve core sealing effect, and achieve the effects of ensuring hygiene and safety, ensuring health and safety, and improving use safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

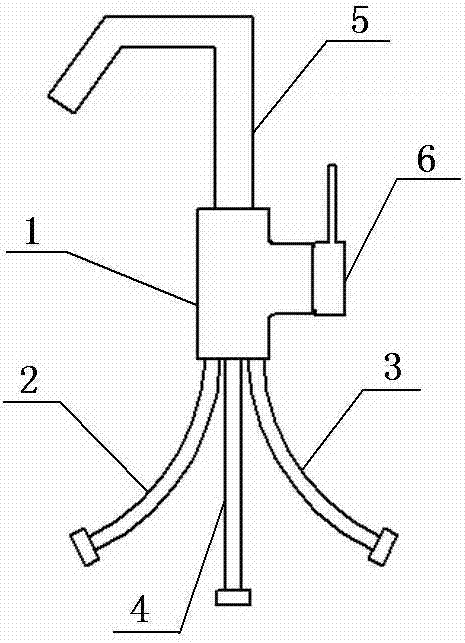

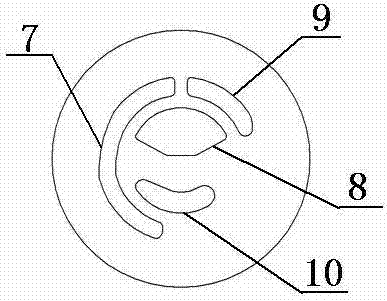

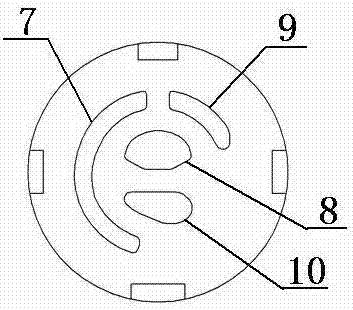

[0039] like Figures 1 to 10 As shown in the first embodiment of the present invention, a water faucet that can improve the safety of heating and heat exchangers has a structure that: the faucet housing 1 is provided with a cold water inlet port for connecting with a tap water pipe. The shell is also provided with a cold water outlet port for connecting with the cold water inlet of the heating heat exchanger heat exchange tube, and the shell is also provided with a hot water outlet port for connecting with the hot water outlet of the heating heat exchanger heat exchange tube. Water inlet port, when in use, the cold water inlet port of the faucet is connected to the tap water pipe through the connected hose 2, and the cold water outlet port of the faucet is connected to the cold water inlet of the heating heat exchanger heat exchange pipe through the connected hose 3 connected, the hot water inlet port of the faucet is connected with the hot water outlet of the heat exchange tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com