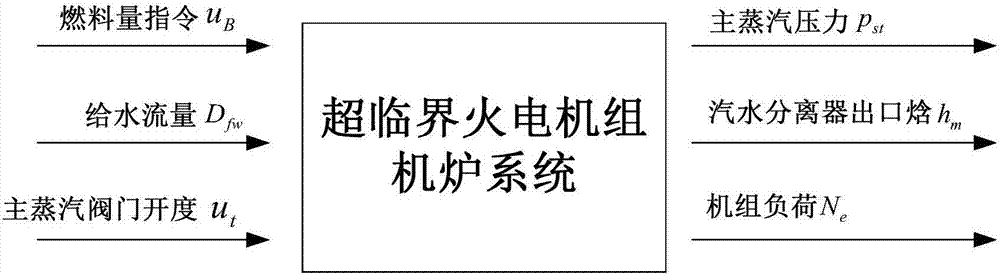

Double-layer control system for load tracking for supercritical thermal power unit turbine-boiler system

A technology for thermal power units and system load, applied in general control systems, adaptive control, control/regulation systems, etc., can solve problems such as poor optimal trajectory tracking effect, and achieve the effect of reducing design difficulty and good load tracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

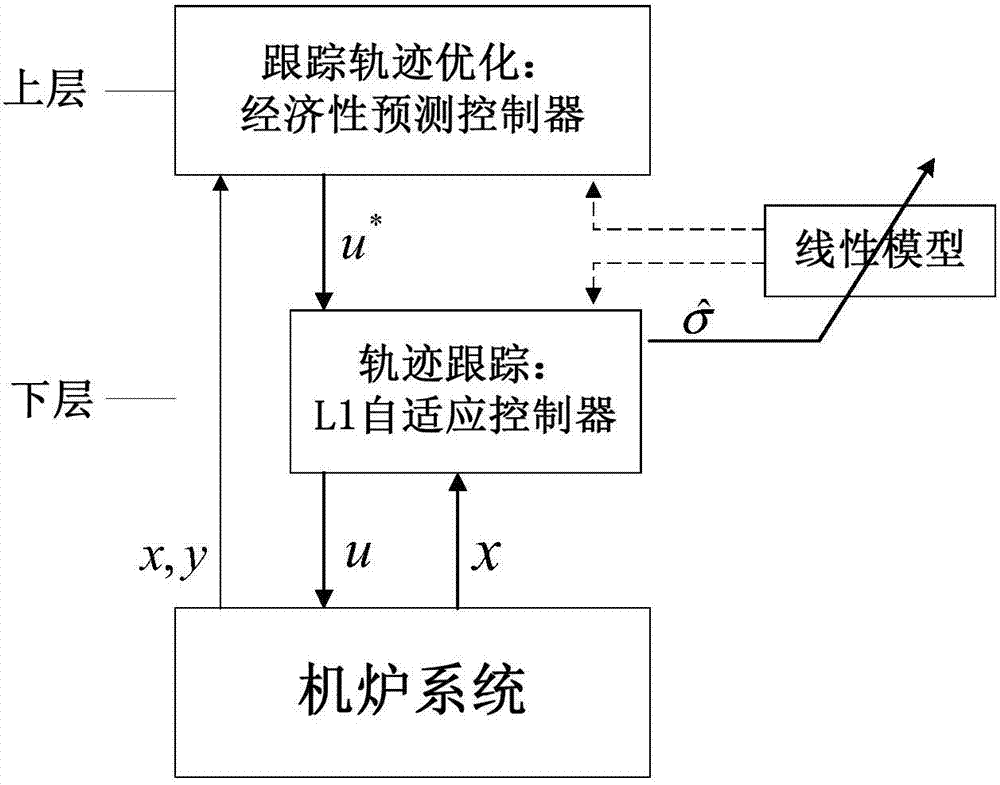

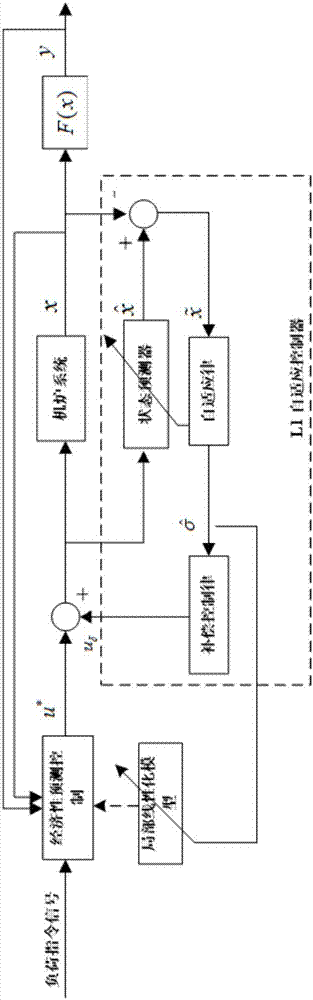

[0058] like figure 2 and image 3 As shown, it is a block diagram of the control system implementation scheme of the present invention, wherein the economical linear predictive controller adopts a linearized model of the machine furnace system, and optimizes the optimal tracking of the machine furnace system according to the actual economic requirements of the machine furnace system. trajectory; the lower layer L1 adaptive controller consists of a state predictor, adaptive law and compensation control law. According to the linear model of the machine furnace system, the state predictor is designed, and the adaptive law is designed. According to the difference between the output state of the state predictor and the measured s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com