Knapsack type electric fertilizer applicator

A knapsack and fertilizer applicator technology, applied in fertilization devices, fertilizer applicators with centrifugal wheels, applications, etc., can solve problems such as limited weight, high labor intensity, and impact on health, so as to reduce fatigue and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

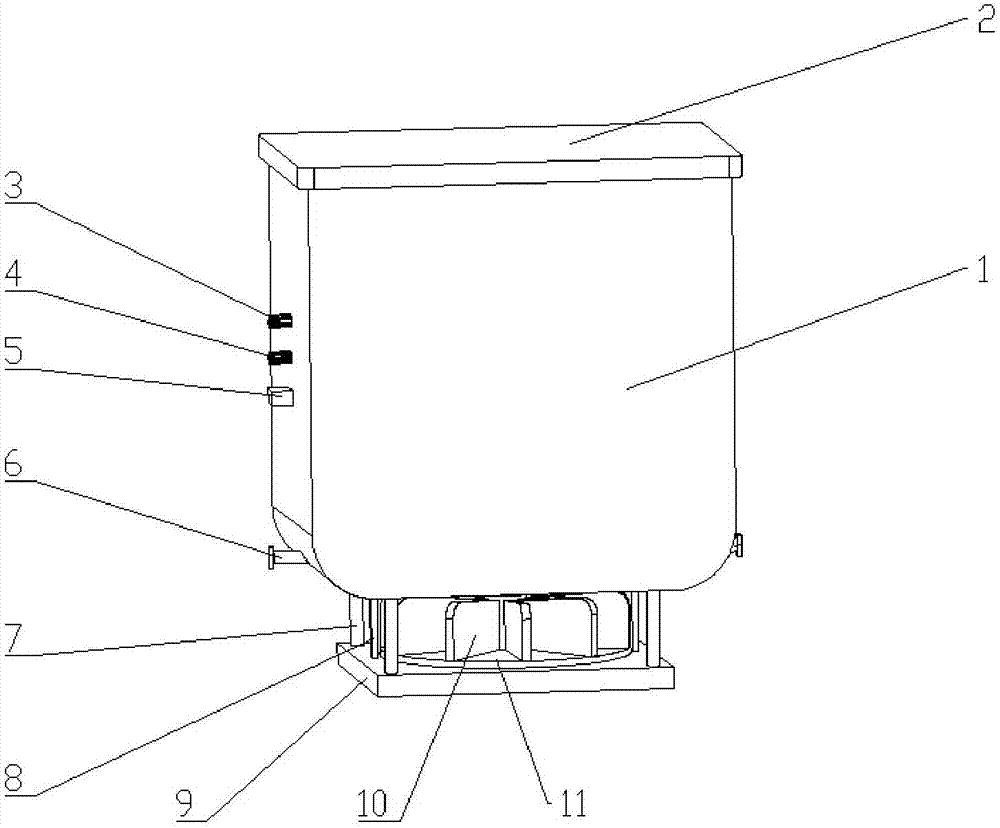

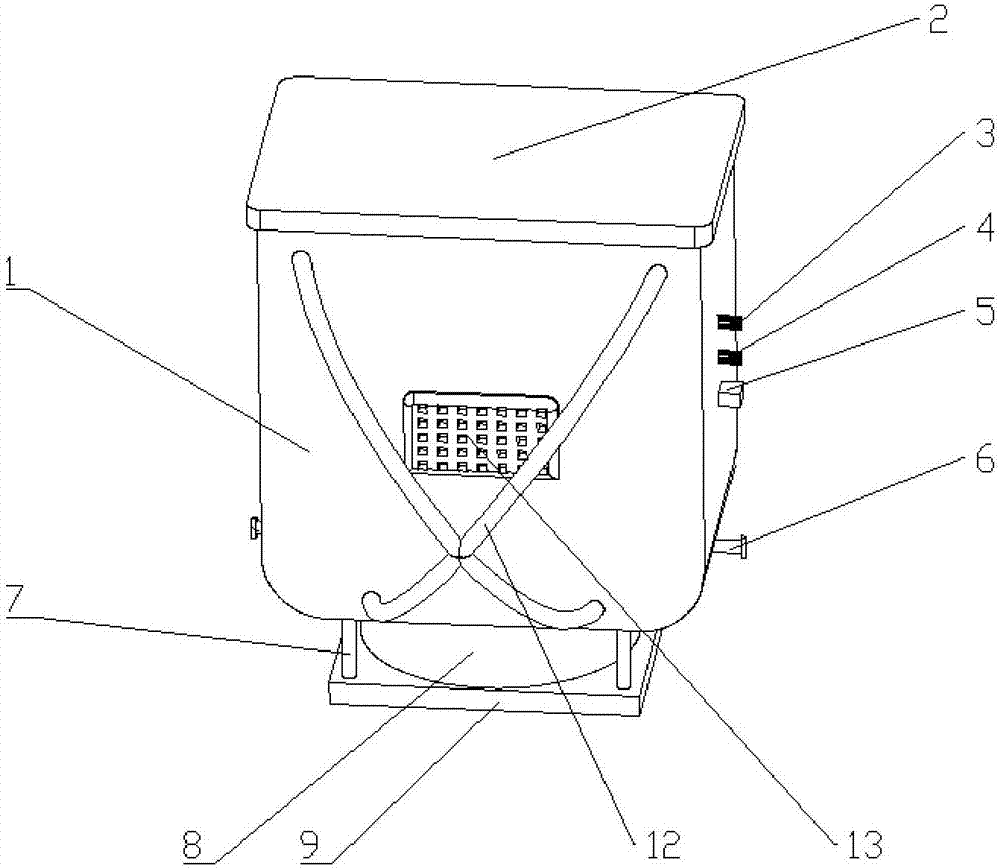

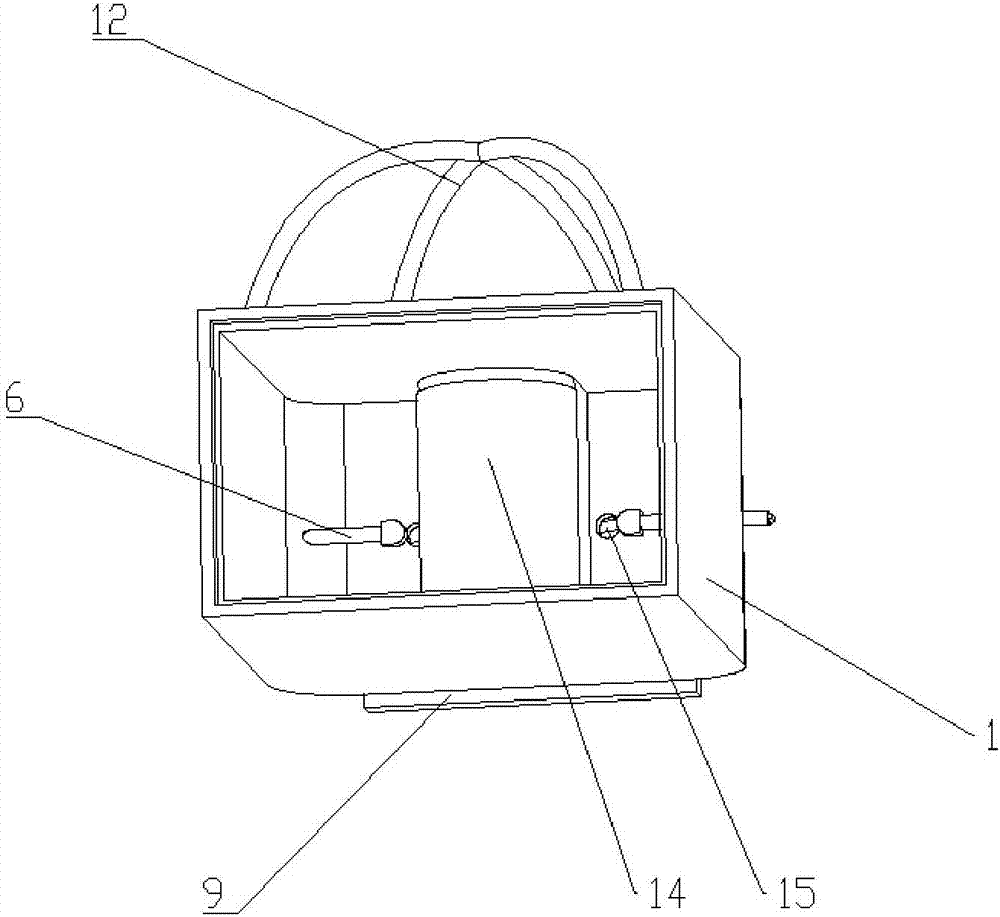

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] Such as Figure 1 to Figure 6 As shown, the knapsack electric fertilizer applicator includes a box body 1 and a back belt 12 arranged at the front end of the box body 1. The bottom of the box body 1 is provided with a discharge hole 15, and the side wall of the box body 1 is provided for controlling the size of the discharge hole 15. cock 6, the lower end of the box body 1 is provided with a spreading device and a power supply device; specifically, the spreading device includes an inner cover box 14-1 arranged at the inner lower end of the box body 1, and the upper end of the inner cover box 14-1 is provided with an inner cover Shell 14, the lower end of inner cover box 14-1 is provided with through hole 20 and fixing hole 21, and the motor 17 that is provided with fan blade disc 11 is fixed in the through hole of inner cover box 14-1, and the inner cover box 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com