A sheet metal creasing and grooving machine capable of automatic and continuous unwinding

A technology of grooving machine and indentation, which is applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve the problems of consuming manpower labor and increasing the production time of indentation and grooving, and achieves reduction of manpower labor, good cutting effect, The effect of preventing deformation and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

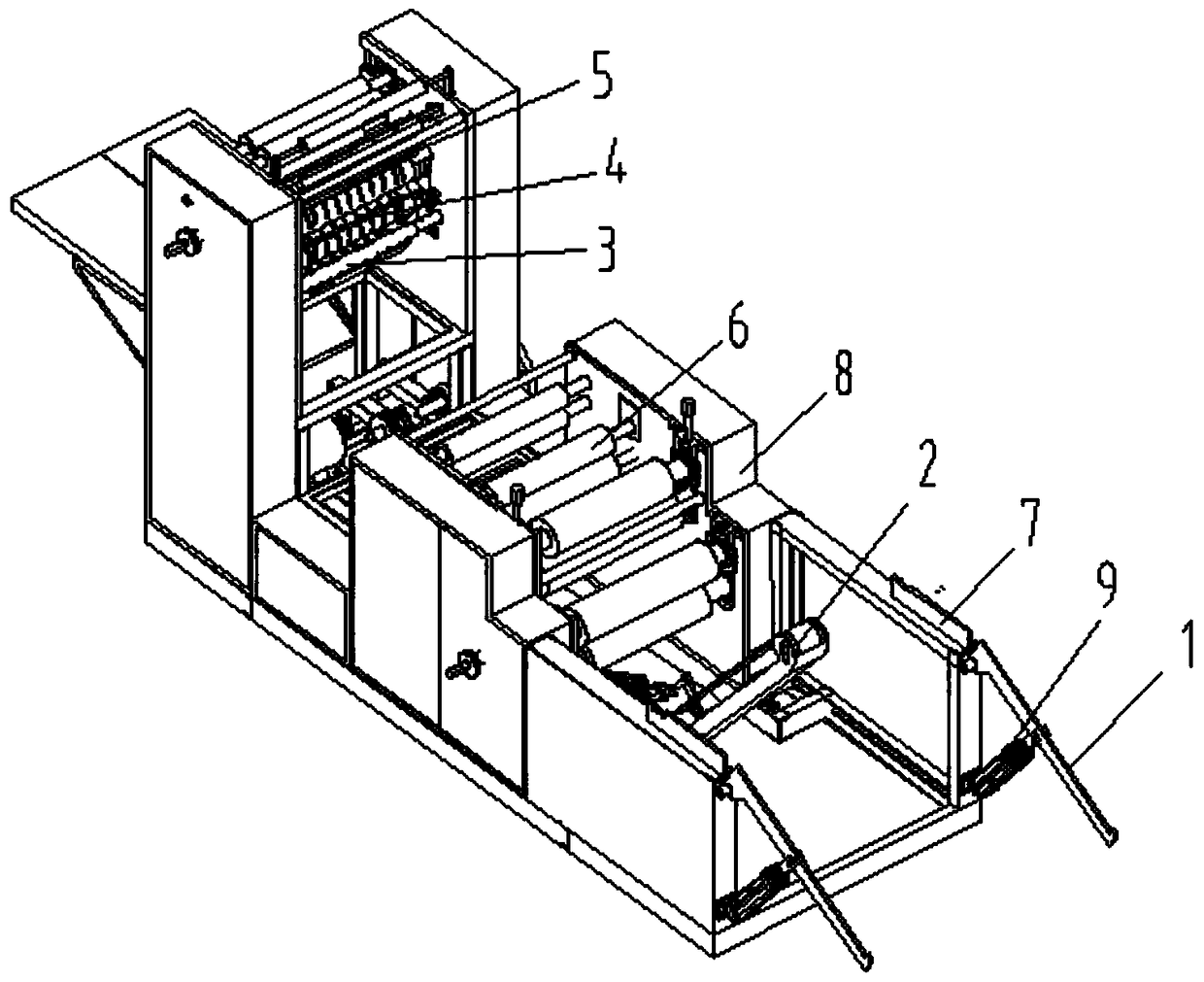

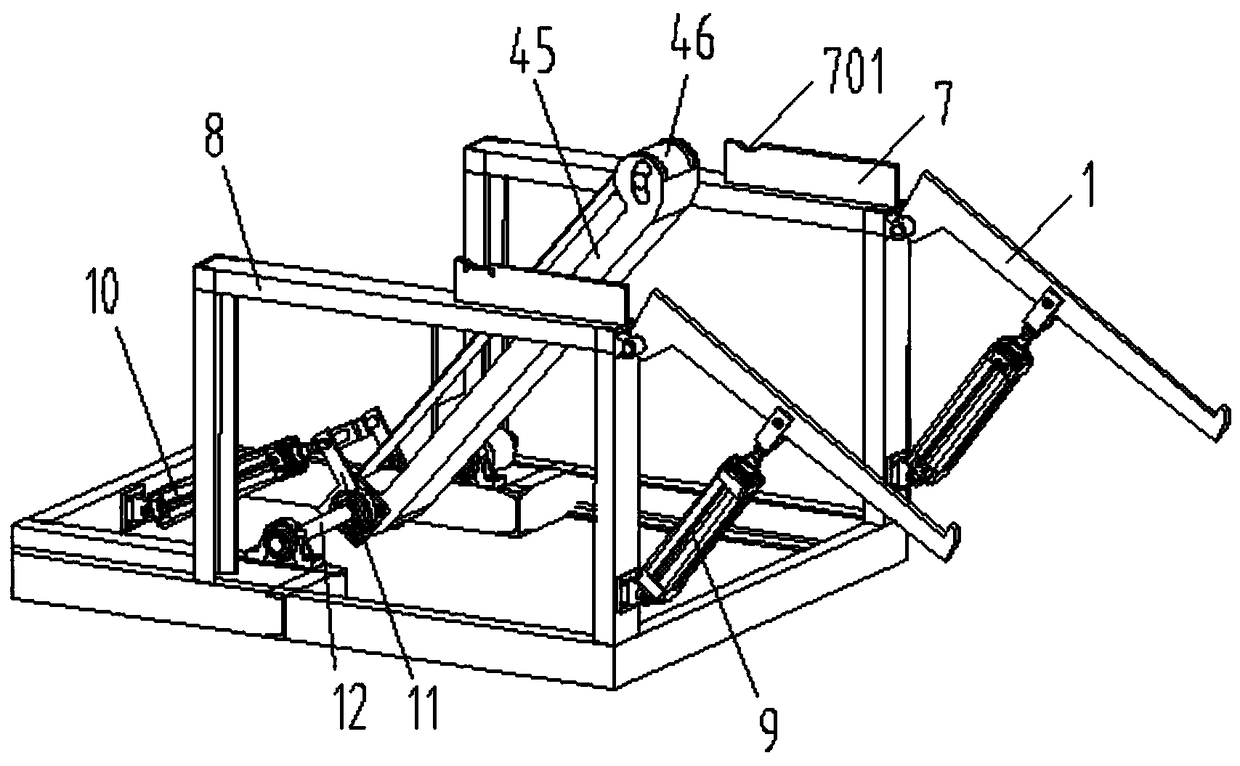

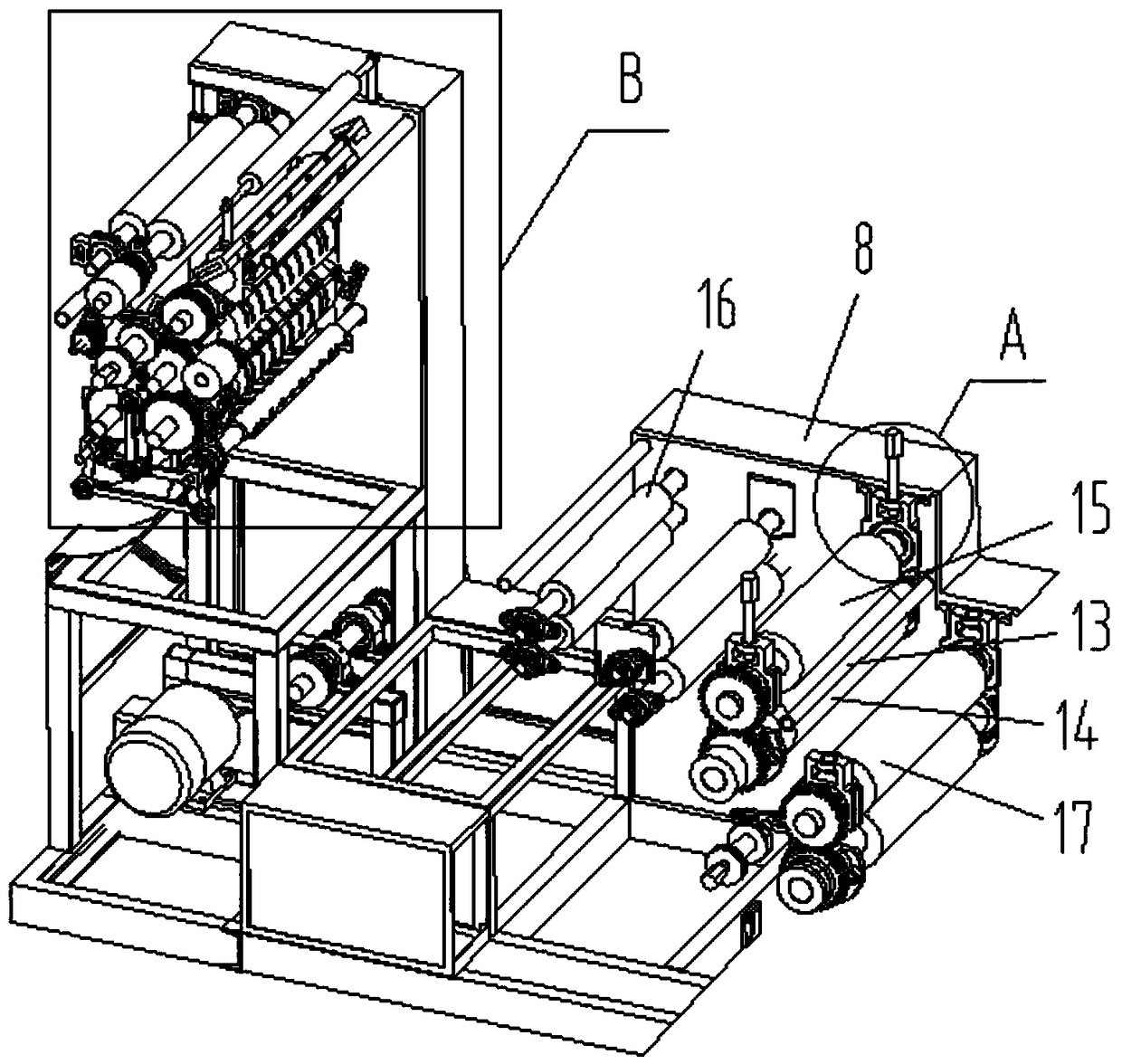

[0036] Such as Figure 1-Figure 9 As shown, the concrete structure of the present invention is: a kind of iron sheet indentation groove machine that can automatically unwind continuously, it comprises frame 8, and the right part of described frame 8 is provided with unwinding plate 7, and described The unwinding plate 7 is provided with an unwinding groove 701 that cooperates with the iron reel, and the frame 8 on the left side of the unwinding groove 701 is provided with a conveying device 6, and the unwinding groove 701 and the conveying guide cylinder 13 are provided with There is a conveying guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com