A bar processing device

A bar processing and processing mechanism technology, applied in metal processing, feeding devices, metal processing equipment, etc., can solve the problem of inability to process and cut the front and rear ends of the bar at one time, and achieve the realization of free positioning and automatic installation. Clamp, avoid the effect of clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

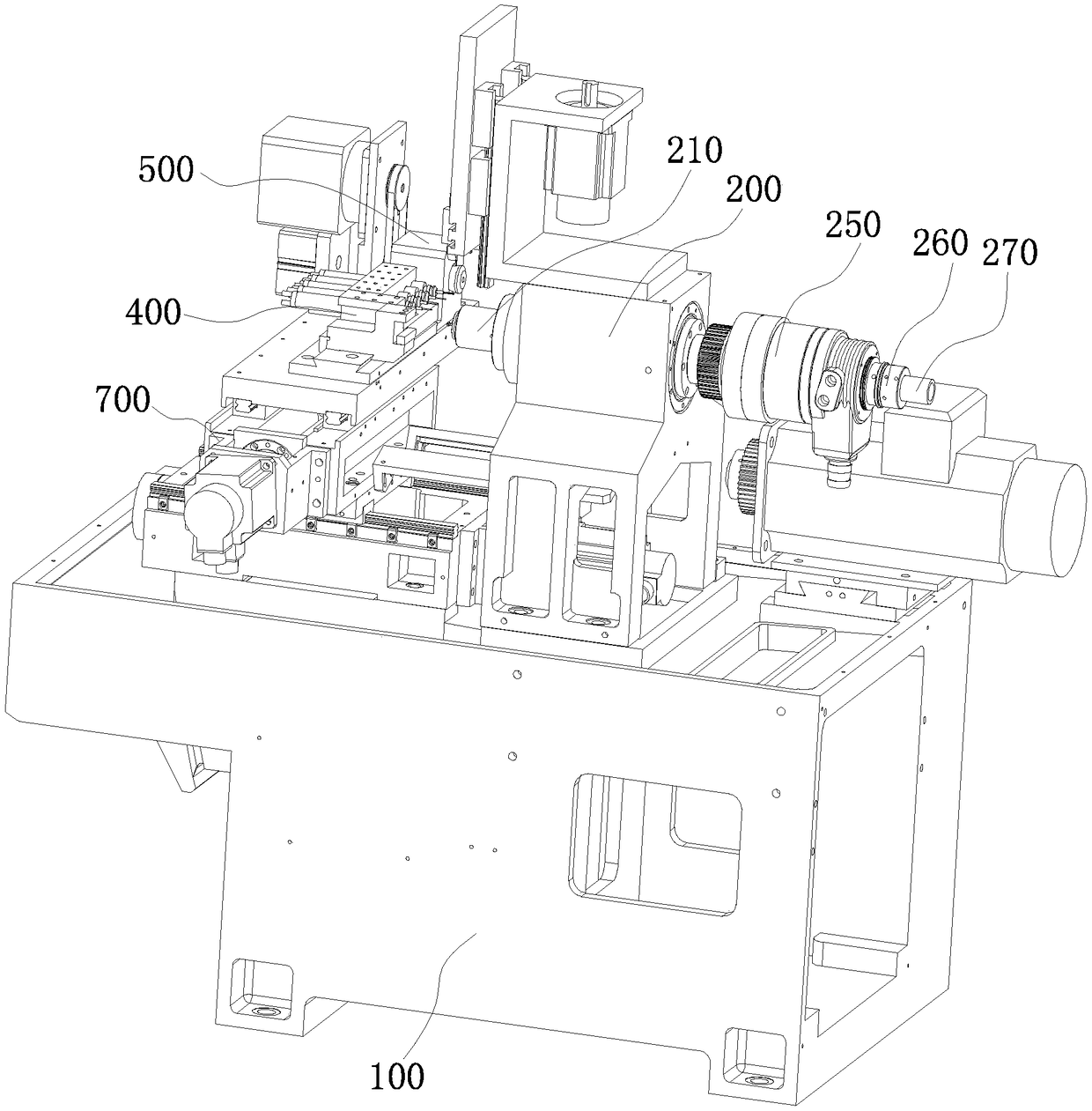

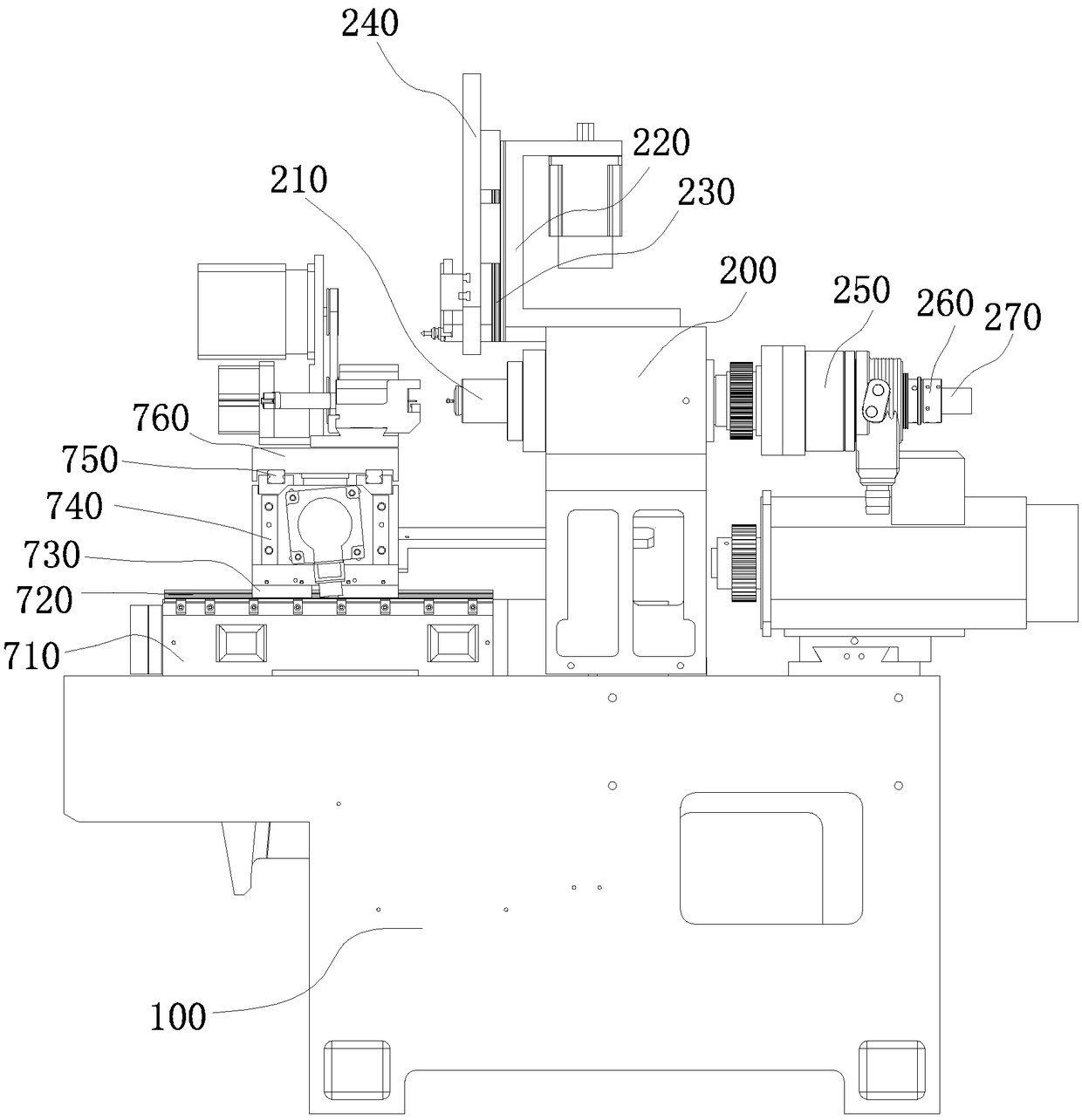

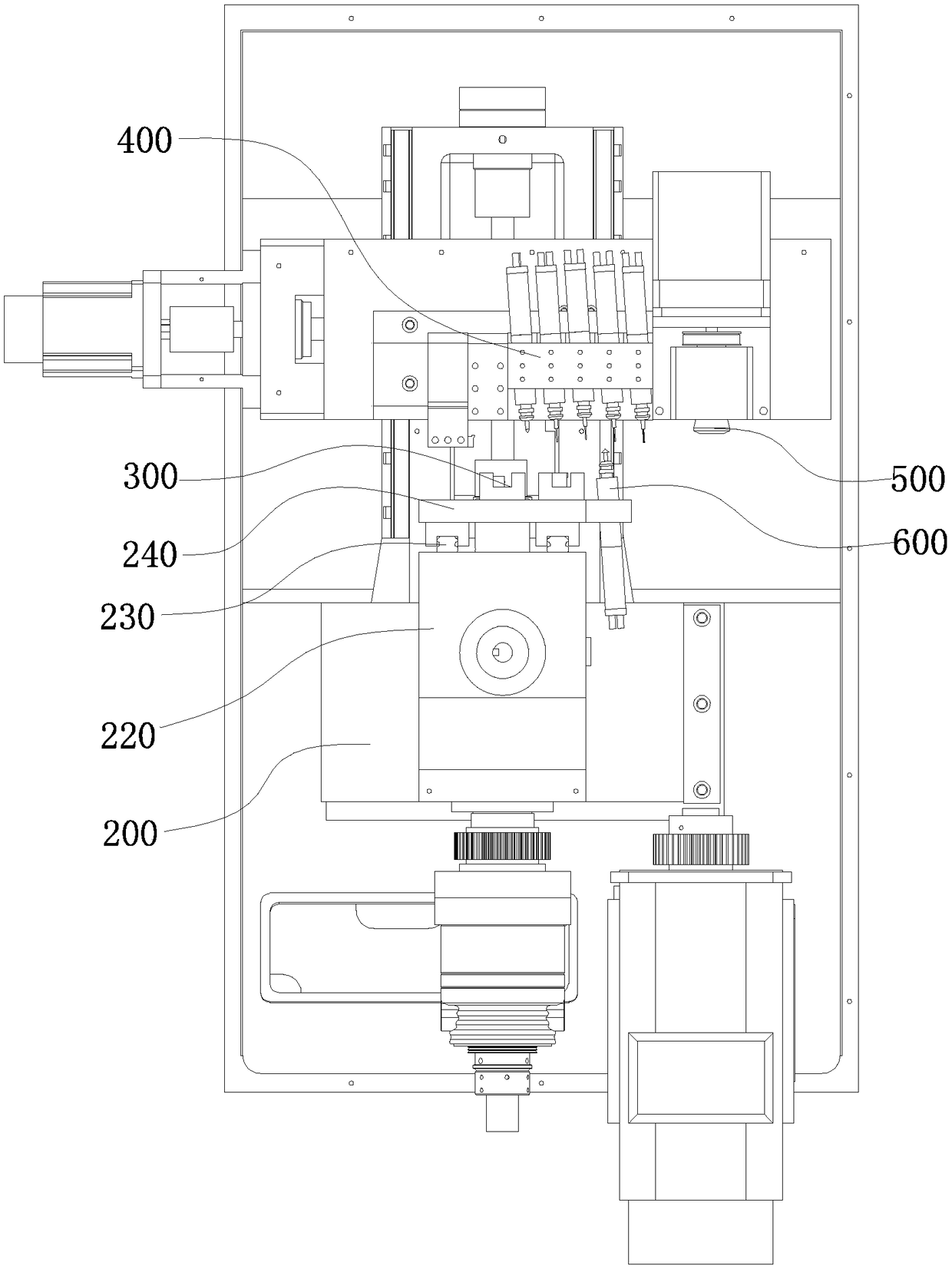

[0037] like figure 1 , figure 2 , image 3 As shown, a bar processing device includes: a bed base 100, a spindle box 200, a cutting mechanism 300, a first processing mechanism 400, a clamping mechanism 500 and a second processing mechanism 600, which are generally used for processing rod-shaped parts, and are simple In other words, the strip-shaped bar is firstly processed on the front end, and then cut to form a small section of bar, and then the rear end of the small section of bar is processed.

[0038] It is worth pointing out here that the bar processing device is for long materials that need to be processed at the other end, such as long bars. After the front end is processed, it is cut into short bars, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com