Electroplastic shearing machining device and using method thereof

A processing device, electroplastic technology, applied in shearing device, metal processing, metal processing equipment and other directions, can solve the problems of shearing difficulty, large deformation resistance, environmental pollution, etc., to reduce shear deformation resistance and prolong service life. Longevity, effect of avoiding softening annealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

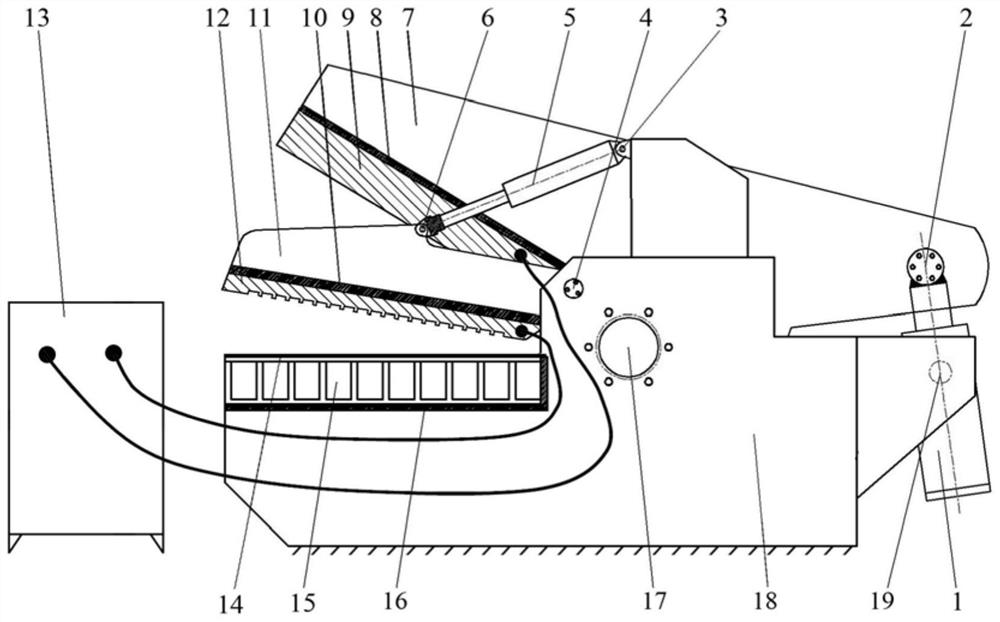

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other without conflict, and the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

[0029] Referring to the accompanying drawings, the present embodiment, according to an aspect of the present invention, provides an electroplastic shearing device, comprising a fixed shearing component, a movable shearing component, a plate pressing component and a pulse power source 13. The fixed shearing component The shearing component is connected with the movable shearing component, the fixed shearing component is used to support the metal plate, the movable shearing component is used to cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com