Smart card production method and device

A production method and production device technology, applied in the field of smart cards, can solve problems such as inconsistent data structures, high risk of pairing errors, and low efficiency of smart card production, so as to reduce the probability of errors and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

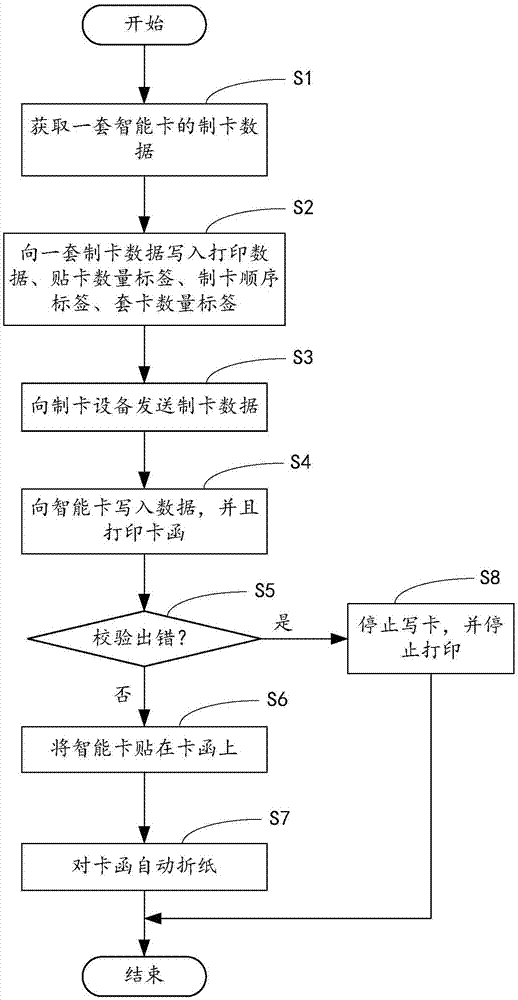

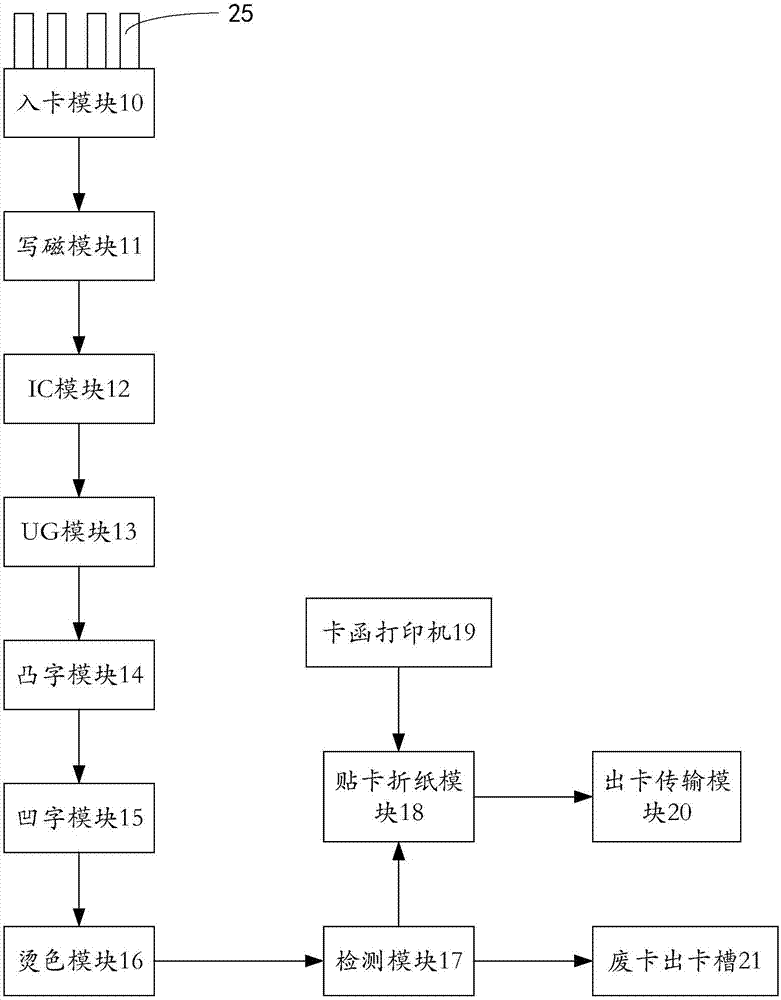

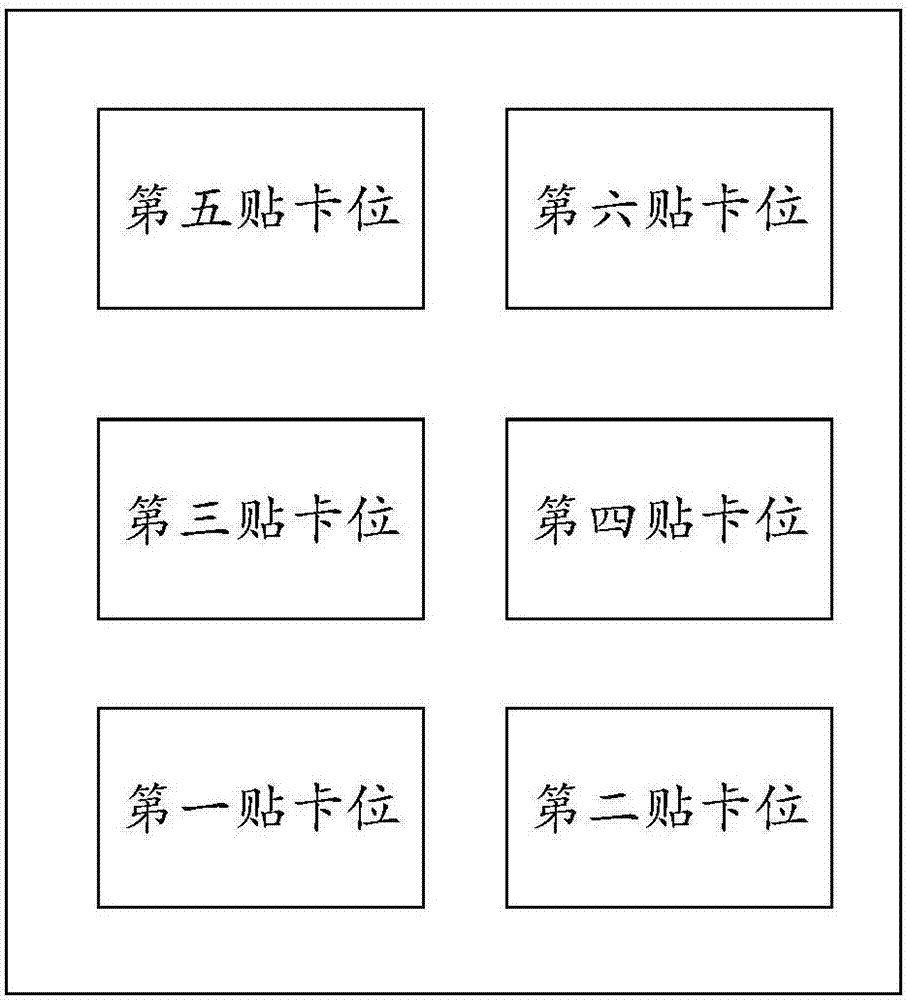

[0027] The smart card production method of the present invention is used to realize the production of smart cards, especially for the production of complete sets of smart cards. The complete set of smart cards referred to in the present invention includes a plurality of associated smart cards, and the plurality of associated smart cards need to be pasted on a card holder. For example, if the same applicant applies for multiple smart cards at the same bank, multiple smart cards need to be pasted on a card letter and mailed. Therefore, the smart card production method of the present invention is applied to the A method of producing multiple smart cards on a letter. The intelligent production device of the present invention is a software program that needs to be used in the smart card production process, such as the application program running on the card making equipment, and the production device of the present invention is used to realize the above-mentioned smart card producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com