Automatic anti-collision noise reduction device used on pipe gravity conveying frame

A technology for conveying racks and pipes, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of harsh impact, mutual collision, and low controllability of steel pipe rolling, and achieve noise reduction and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

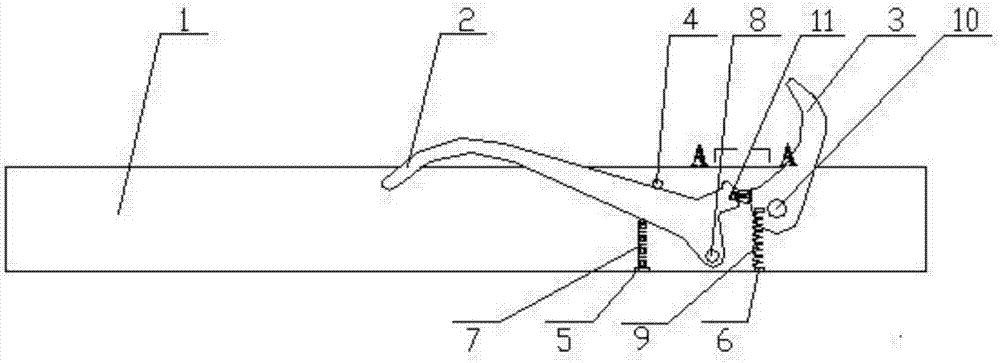

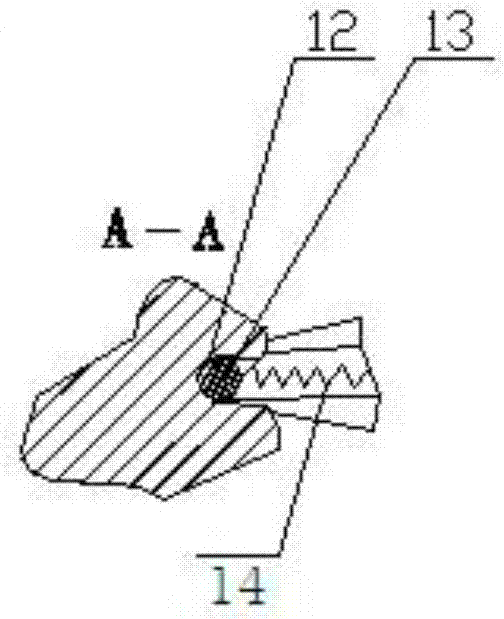

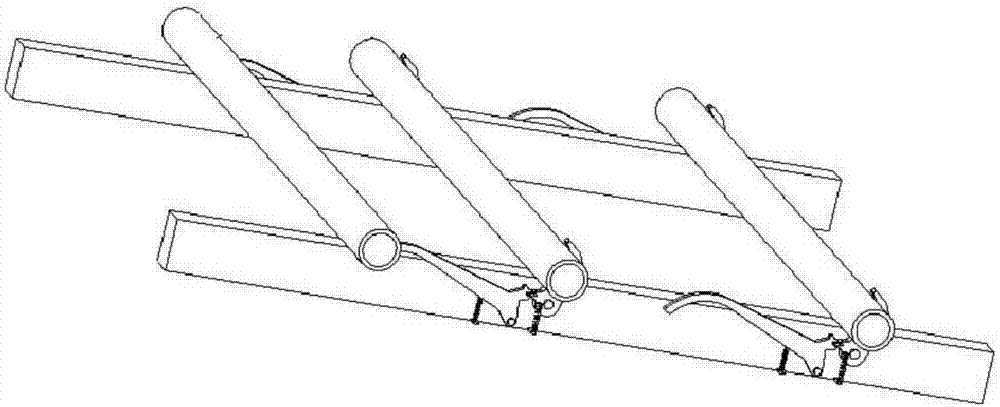

[0023] Such as figure 1 and 2 Shown is an automatic anti-collision and noise reduction device used on a pipe gravity transmission rack, including a flat plate 1, a trigger lever 2, a pipe shift hook 3 and a limit nail 4, and a first spring is fixed under one side of the flat plate 1 The fixed plate 5 and the second spring fixed plate 6, the trigger lever 2 is elastically connected to the first spring fixed plate 5 through the first spring 7, and is connected to the side of the flat plate 1 through the first fixed shaft 8; 3. The second spring 9 is elastically connected to the second spring fixing plate 6, and is rotationally connected to one side of the plate 1 through the second fixing shaft 10; One end is provided with a movable groove 12, and a hook shaft 13 is fixedly installed in the movable groove 12, and the hook shaft 13 is fastened and connected with the card groove 11 through a third spring 14; the limiting nail 4 is fixed on One side of the flat panel 1, and above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com